Cutting Unit Characteristics

The dual knob bedknife-to-reel adjustment system

incorporated in this cutting unit simplifies the

adjustment procedure needed to deliver optimum

mowing performance. The precise adjustment

possible with the dual knob/bedbar design gives the

necessary control to provide a continual self-sharpening

action-thus maintaining sharp cutting edges, ensuring

good quality-of-cut, and greatly reducing the need for

routine back lapping.

Daily Adjustments of Cutting Unit

Prior to mowing each day, or as required, each cutting

unit must be checked to verify proper bedknife-to-reel

contact.

This must be performed even though

quality of cut is acceptable.

1. Lower the cutting units onto a hard surface, shut off

the engine, and remove the ignition key.

2. Slowly rotate the reel in a reverse direction,

listening for reel-to-bedknife contact. If no contact

is evident, turn the bedknife adjusting knobs

clockwise, one click at a time, until light contact is

felt and heard.

Note:

The adjustment knobs have detents

corresponding to 0.0009 in. (0.023 mm) bedknife

movement for each indexed position.

3. If excessive contact is felt, turn the bedknife

adjusting knobs counterclockwise, one click at

a time until no contact is evident. Then turn

the bedknife adjusting knobs one click at a time

clockwise, until light contact is felt and heard.

Important:

Light contact is preferred at all

times. If light contact is not maintained,

the bedknife/reel edges will not sufficiently

self-sharpen and dull cutting edges will result

after a period of operation. If excessive contact

is maintained, bedknife/reel wear will be

accelerated, uneven wear can result, and quality

of cut may be adversely affected.

Note:

As the reel blades continue to run against

the bedknife, a slight burr will appear on the front

cutting edge surface along the full length of the

bedknife. If a file is occasionally run across the

front edge to remove this burr, improved cutting

can be obtained.

After extended running, a ridge will eventually

develop at both ends of the bedknife. These notches

must be rounded off or filed flush with the cutting

edge of the bedknife to ensure smooth operation.

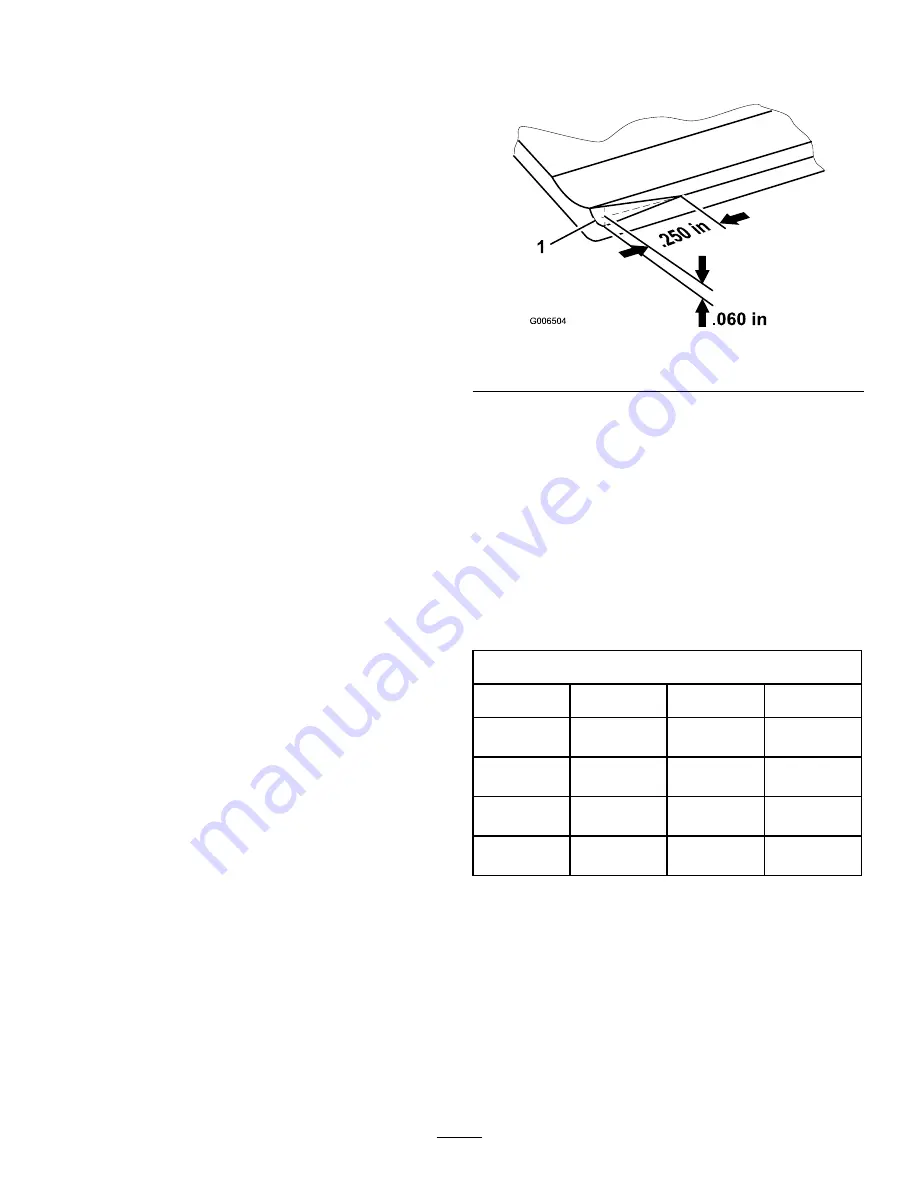

Note:

Over time, the chamfer (Figure 25) will need

to be reground as it is only designed to last 40%

of the bedknife life.

Figure 25

1.

Lead-in chamfer on right end of bedknife

Note:

Do not make lead-in chamfer too large as

it may cause turf tufting.

Servicing Bedknife

The bedknife service limits are listed in the following

charts.

Important:

Operating the cutting unit with the

bedknife below the “service limit” may result in

poor after-cut appearance and reduce the structural

integrity of the bedknife for impacts.

Bedknife Service Limit Chart

Bedknife

Part No.

Bedknife Lip

Height *

Service Limit

*

Low HOC

(Optional)

110-4084

.220

.190"

EdgeMax®

(Production)

108-9095

.270

.190"

Standard

(Optional)

108-9096

.270

.190"

Heavy Duty

(Optional)

110-4074

.370

.190"

16