1

Inspection

Parts needed for this procedure:

1

Cutting unit

Procedure

After the cutting unit is removed from the box, inspect

the following:

1. Check each end of the reel for grease. Grease should

be visibly evident in the reel bearings and internal

splines of the reel shaft.

2. Ensure that all nuts and bolts are securely tightened.

3. Make sure the carrier frame suspension operates

freely and does not bind when moved back and forth.

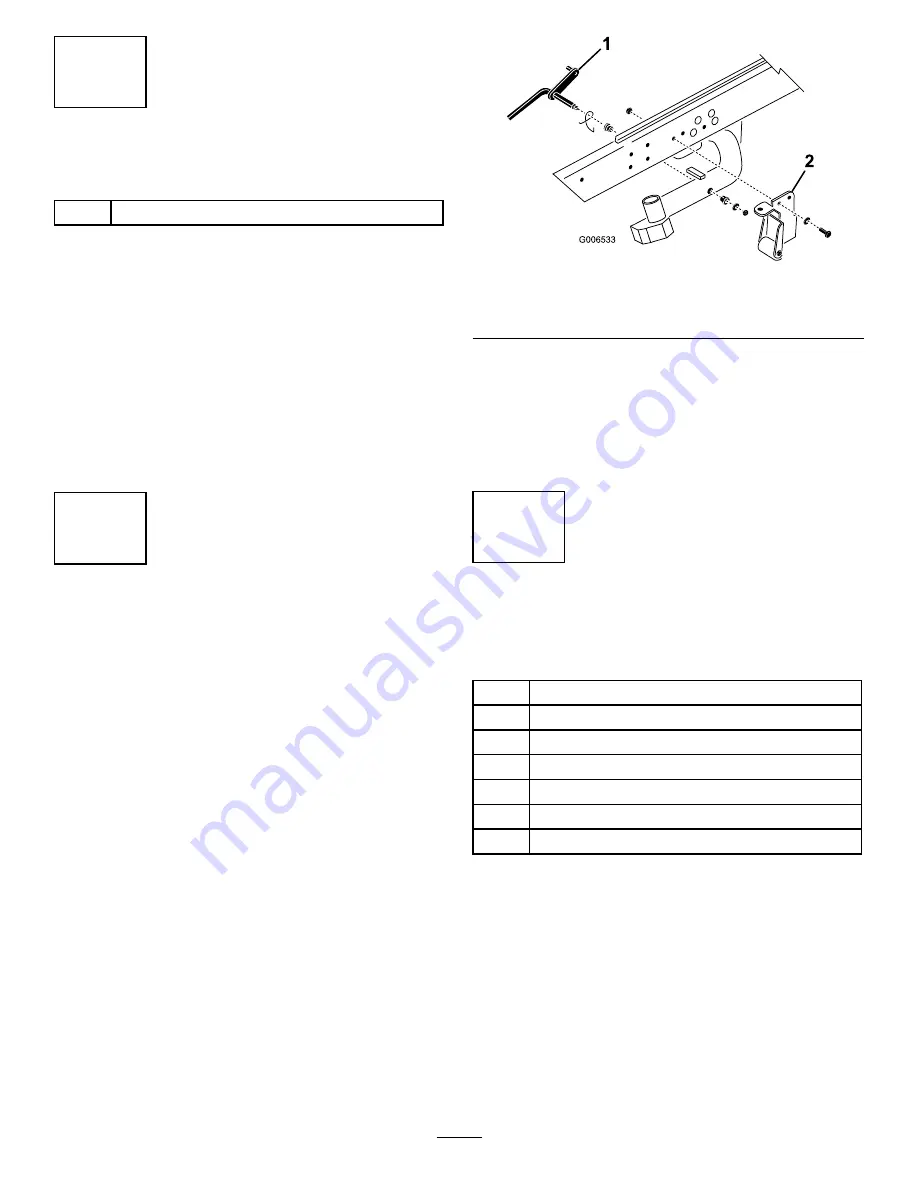

2

Removing the Tipper

Assemblies

No Parts Required

Procedure

The tipper assemblies must be removed from the #1, #2

and #3 lift arms to avoid interference with the cutting

unit carrier frames.

1. Remove the lock nut and washer securing the pivot

rod to the #2 lift arm (Figure 3). Remove the

pivot rod and spring from the lift arm. Repeat the

procedure on the #1 and #3 lift arms.

Figure 3

1.

Pivot rod

2.

Tipper support bracket

w/roller

Note:

The tipper bracket w/roller and the tipper

support brackets are not required when operating

the DPA cutting units (Figure 3). They may be

removed if desired.

2. Disconnect the lift chains from the cutting units, if

attached.

3

Mount the Lift Brackets and

Chains

Parts needed for this procedure:

5/7

Lift chain

5/7

Chain bracket

5/7

U-bolt

10/14

Nut

5/7

Screw

5/7

Washer

5/7

Nut

Procedure

Mount a chain bracket to each lift arm with a U-bolt and

2 nuts. Position the brackets as follows:

Note:

Refer to Figure 10 to determine the lift arm

number being described.

1. On lift arms #1, #4 and #5, position the chain

brackets and U-bolts 15 inches behind the center

line of the pivot knuckle (Figure 4). On lift arms #1

and #5 the brackets should be rotated to the right

10 degrees from vertical (Figure 4). On lift arm #4

5