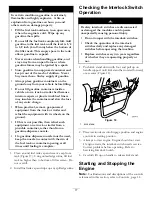

Figure 23

1.

Air cleaner cover

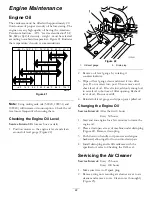

3. If foam element is dirty, remove it from paper

element (Figure 24). Clean thoroughly.

A. Wash foam element in a solution of liquid soap

and warm water. Squeeze to remove dirt, but do

not twist because the foam may tear.

B. Dry by wrapping in a clean rag. Squeeze rag and

foam element to dry, but do not twist because

the foam may tear.

C. Saturate element with clean engine oil. Squeeze

element to remove excess oil and to distribute oil

thoroughly. An oil damp element is desirable.

Figure 24

1.

Foam element

2.

Paper element

4. When servicing foam element, check condition of

paper element. Clean or replace every 100 hours or

as required.

5. Install foam element, paper element, and air cleaner

cover.

Important:

Do not operate the engine without

the air cleaner element because extreme engine

wear and damage will likely result.

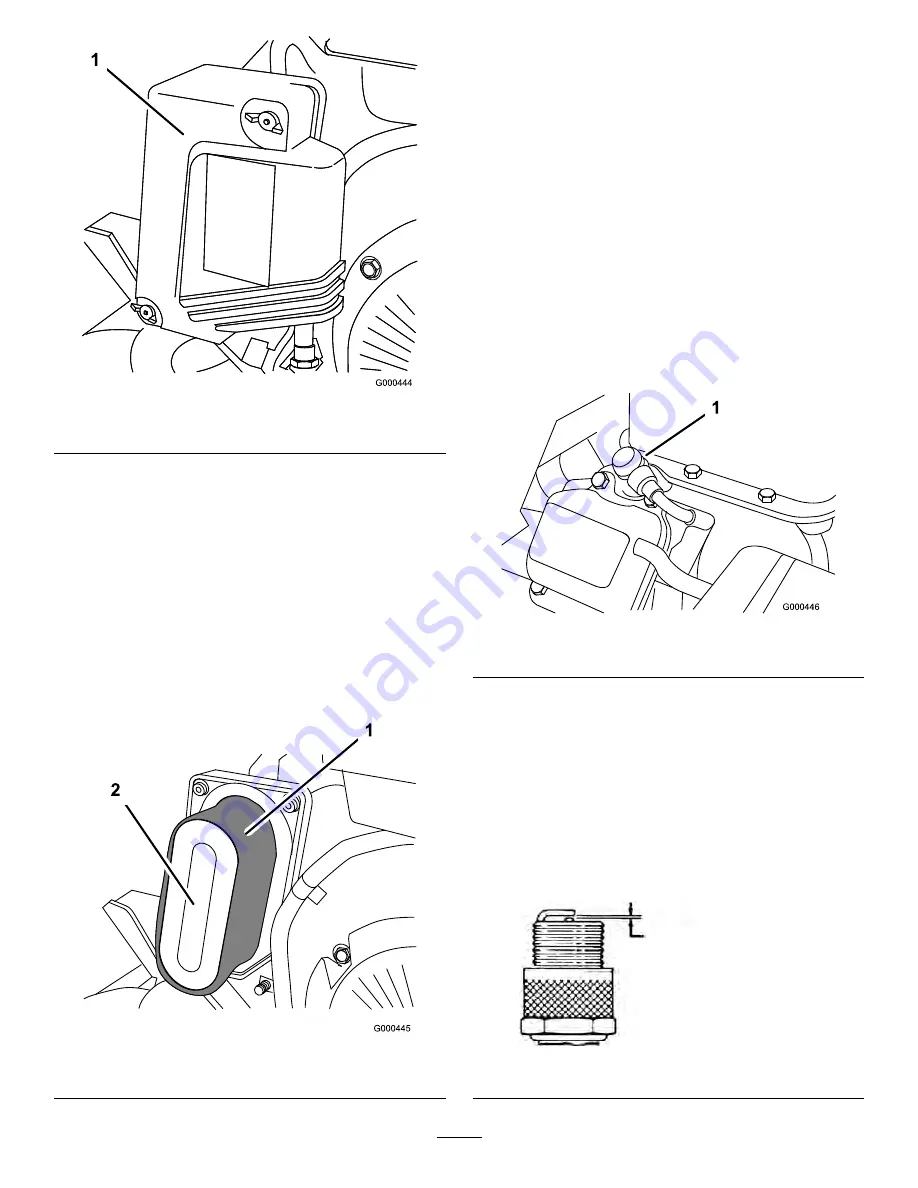

Replacing the Spark Plug

Service Interval:

Every 100 hours

Use an NGK BPR 5ES spark plug or equivalent. Correct

air gap is 0.028-0.032 inch.

1. Pull molded wire off spark plug (Figure 25).

Figure 25

1.

Spark plug wire

2. Clean around spark plug and remove plug from

cylinder head.

Important:

Replace a cracked, fouled, or dirty

spark plug. Do not sand blast, scrape, or clean

electrodes because engine damaged could result

from grit entering the cylinder.

3. Set air gap at 0.028-0.032 inch (Figure 26). Install

correctly gapped spark plug and tighten firmly to

17 ft.-lb.

0.028−0.032 in.

G000448

Figure 26

23

Summary of Contents for 04018 Greensmaster Flex 18

Page 9: ...104 2621 1 Read the Operator s Manual 9 ...

Page 39: ......