Greensmaster Flex 18/21

Traction and Reel Drive System

Page 4 – 14

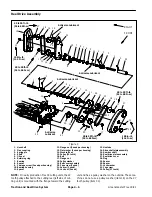

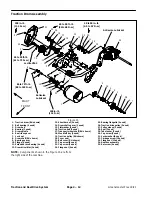

Traction Drum Assembly (Fig. 15)

1. Assemble hub/spindle assembly (Fig. 17):

A. Press one bearing into drum hub by applying

pressure to outer bearing race. Install bearing

spacer into drum hub and fill cavity between spacer

and drum hub with Mobil High Temperature

XHP–222 grease (or equivalent). Press second

bearing into drum hub by applying pressure to outer

bearing race. Make sure that spacer is centered in

hub.

B. Pack rear cavity of oil seals with Mobil High Tem-

perature XHP–222 grease (or equivalent). Fill hub

cavity between bearings and seal positions with Mo-

bil High Temperature XHP–222 grease (or equiva-

lent).

C. Press seals into hub so the seals are flush with

the hub surface. Lightly grease lip of both seals.

D. Lightly grease the drum spindle and slide spindle

into the hub. Slide seal ride spacer onto spindle and

insert spacer into oil seal. Secure drum spindle to

prevent it from turning and then secure spindle to the

hub with lock nut.

2. Position traction drums to hub/spindle assembly. Se-

cure each traction drum to hub/spindle with four (4) cap

screws and lock washers. Torque cap screws 100 in–lb

(11.3 N–m).

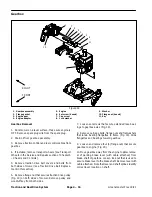

Traction Drum Installation (Fig. 15)

1. Position machine on a level surface. Make sure en-

gine is OFF. Remove spark plug wire from the spark

plug.

2. If removed, loosely install bearings (item 11) and

bearing flangettes (item 10) to machine frame. Make

sure that extended race of bearings is positioned to the

outside of the frame.

3. Pivot mower back and position traction drum assem-

bly under the mower. Lower mower onto traction drum.

4. Position drum spacers to sides of drum.

5. Insert bar stock or other suitable tool through spokes

of drum to keep drum from turning.

NOTE: The left side drum shaft has left hand threads

(Fig. 16).

6. Apply antiseize lubricant to drum shaft (item 8)

threads and install shafts through bearings, spacers and

into drum. After both shafts are installed, torque drum

shafts from 65 to 75 ft–lb (88 to 102 N–m).

7. Tighten the fasteners that secure the bearing flan-

gettes (item 10) to the machine frame. Tighten the bear-

ing set screw (item 25) to secure each bearing to the

drum shaft. Torque set screws from 40 to 50 in–lb (4.5

to 5.7 N–m).

NOTE: The left side drum pulley has left hand threads

(Fig. 16).

8. Apply antiseize lubricant to the external threads of

the drum shafts. Secure both drum pulleys (item 19) to

the drum shafts.

NOTE: The right side wheel shaft has left hand threads

(Fig. 16).

9. Apply Loctite #242 (or equivalent) to the threads of

the transport wheel shafts (item 17). Install wheel shafts

into drum drive shafts. Torque wheel shafts from 45 to

55 ft–lb (61 to 75 N–m).

10.Install traction belts and adjust belt tension (see

Traction Drive Belt Replacement in this section).

11. Install traction drive belt cover and secure with flange

nut. Torque flange nut 100 in–lb (11.3 N–m).

12.Install transport wheels if they were attached (see

Transport Wheels in the Service and Repairs section of

Chapter 6 – Chassis and Controls).

13.Connect spark plug wire to spark plug.

Summary of Contents for 04022 Greensmaster Flex 21

Page 2: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Page 4: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Page 58: ...Greensmaster Flex 18 21 Page 5 10 Electrical System This page is intentionally blank ...

Page 83: ...Greensmaster Flex 18 21 Page 7 13 Cutting Unit This page is intentionally blank Cutting Unit ...

Page 85: ...Greensmaster Flex 18 21 Page 7 15 Cutting Unit This page is intentionally blank Cutting Unit ...

Page 111: ...Greensmaster Flex 18 21 Groomer Page 8 15 This page is intentionally blank Groomer ...