Greensmaster Flex 18/21

Page 7 – 12

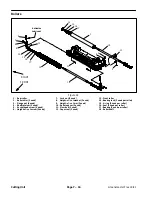

Cutting Unit

Bedknife Service

Bedknife Removal

1. Remove bedbar from cutting unit frame (see Bedbar

Removal in this section).

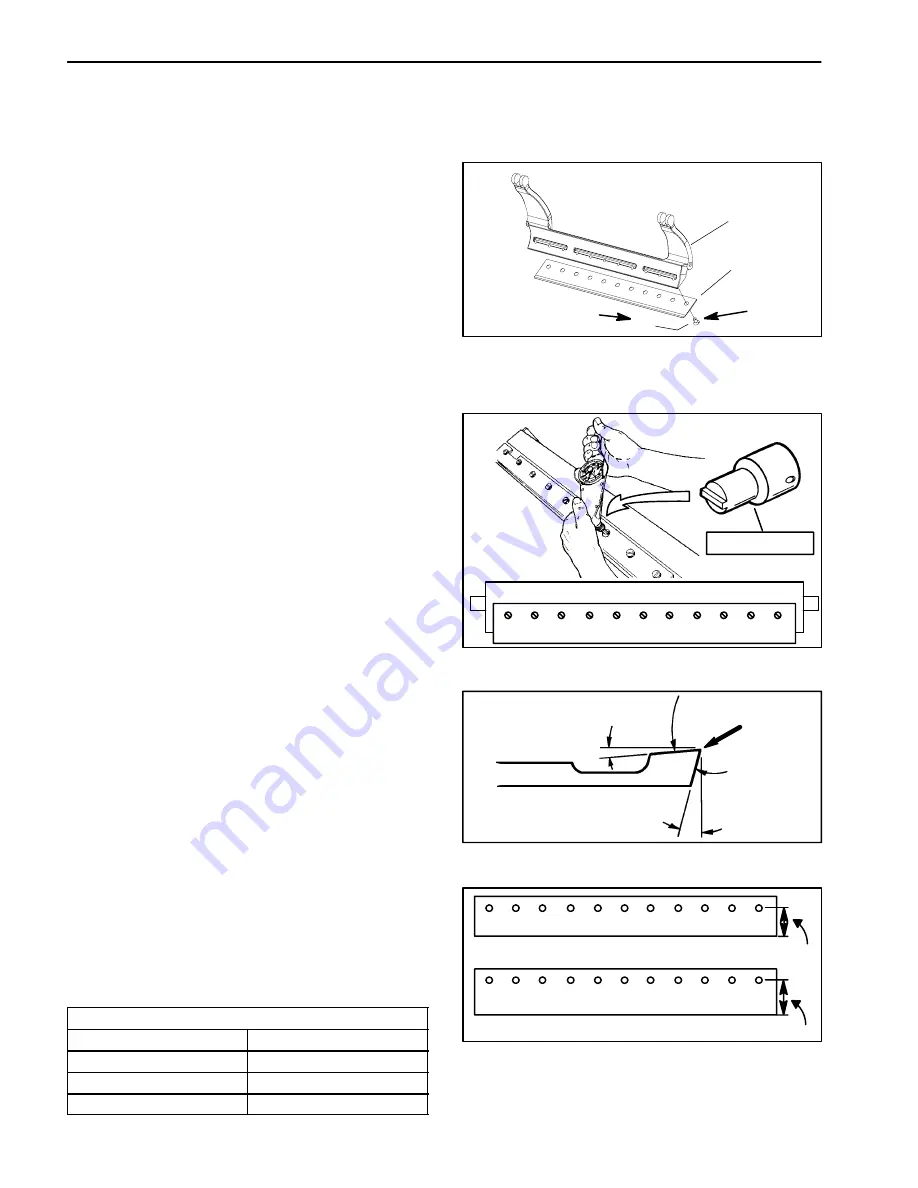

2. Remove screws that fasten bedknife to bedbar using

a socket wrench and bedknife screw tool (see Special

Tools). Discard screws. Remove bedknife from bedbar

(Fig. 17).

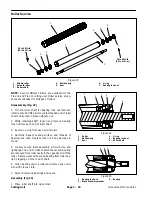

Bedknife Installation

1. Use a scraper to remove all rust, scale and corrosion

from bedbar surface before installing new bedknife.

Also, make sure bedbar threads are clean. If necessary,

use 5/16 – 18UNC 2A tap to chase threads in bedbar.

2. Use new screws to secure bedknife to bedbar. Apply

antiseize lubricant to the screws before installing. Take

care to keep antiseize lubricant from taper on screw

heads.

IMPORTANT: Do not use an impact wrench to tight-

en screws into the bedbar.

3. Install all screws but do not tighten fully. Then, using

a torque wrench and bedknife screw tool, torque screws

from 200 to 250 in–lb (22.6 to 28.2 N–m). Use a torqu-

ing pattern working from the center toward each end of

the bedknife (Fig. 18).

4. Grind bedknife after installation onto bedbar.

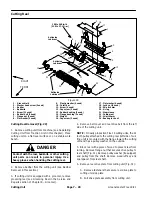

Bedknife Grinding

Since there can be variations in the mounting surface of

the bedbar, a new bedknife will not be perfectly flat after

it is installed. It is therefore necessary to grind a new

bedknife after installing it to the bedbar. Follow the exist-

ing bedknife angle and grind only enough to make sure

the top surface is true (Fig. 19). The bedbar needs to be

removed from mower for proper bedknife grinding.

NOTE: When grinding bedknife, be careful to not over-

heat the bedknife. Remove small amounts of material

with each pass of the grinder. Also, clean and dress

grinding stone often during the grinding process.

1. For bedknife grinding information, refer to TORO

Sharpening Reel and Rotary Mowers Manual, Form

No. 80-300 PT.

Bedknife Grinding Specifications

Standard bedknife relief angle

3

o

(see Fig. 20)

Extended bedknife relief angle

7

o

(see Fig. 20)

Front Angle

13

o

Front Angle Range

13

o

to 17

o

2. After bedknife grinding is complete, install bedbar to

the mower (see Bedbar Installation in this section).

1. Screw

2. Bedknife

3. Bedbar

Figure 17

3

1

2

Antiseize

Lubricant

200 to 250 in–lb

(22.6 to 28.2 N–m)

1

2

4

6

8

3

5

7

9

10

11

Figure 18

# TOR510880

Relief Angle

Front Angle

Top Face

Front

Face

Figure 19

Remove

Burr

Figure 20

1.69” (42.9 mm)

1.88” (47.8 mm)

Standard Bedknife

Extended Bedknife

Summary of Contents for 04022 Greensmaster Flex 21

Page 2: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Page 4: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Page 58: ...Greensmaster Flex 18 21 Page 5 10 Electrical System This page is intentionally blank ...

Page 83: ...Greensmaster Flex 18 21 Page 7 13 Cutting Unit This page is intentionally blank Cutting Unit ...

Page 85: ...Greensmaster Flex 18 21 Page 7 15 Cutting Unit This page is intentionally blank Cutting Unit ...

Page 111: ...Greensmaster Flex 18 21 Groomer Page 8 15 This page is intentionally blank Groomer ...