Greensmaster Flex 18/21

Page 7 – 22

Cutting Unit

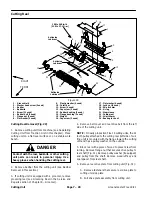

DANGER

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when handling the cutting reel.

IMPORTANT: When installing cutting reel, take care

to not nick or scratch the wear sleeve surfaces as

grease seal failure could result.

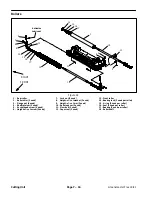

6. Carefully insert cutting reel into LH side plate grease

seals and bearing taking care to not damage wear seal

or grease seals. The reel shaft end with keyway should

be on the left side of the frame.

7. Carefully slide RH side plate and pitch arm onto reel

shaft taking care to not damage wear seal or grease

seals. Secure RH side plate to crossmember with two

(2) shoulder bolts and square nuts (Fig. 32). Torque

shoulder bolts from 210 to 240 in–lb (23.7 to 27.1

N–m).

NOTE: The reel bearing lock nut has left hand threads.

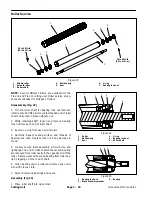

8. Apply antiseize lubricant to internal threads of reel

bearing lock nut. Block reel with a piece of wood to pre-

vent it from turning. Install and tighten the reel bearing

lock nut to the reel shaft.

9. Install reel weight on right side of cutting unit with two

(2) cap screws and flat washers.

10.Install reel drive plate to cutting unit (Fig. 31):

A. Position spacer (item 5) to LH side plate.

B. If cutting unit is equipped with a groomer, install

LH groomer side plate (see Groomer Reel Bearing

Replacement in the Service and Repairs section of

Chapter 8 – Groomer).

C. Position two (2) spacers (item 4) and reel drive

plate to LH side plate.

D. Install two (2) cap screws, flat washers and lock

nuts.

E. Install cap screw and lock washer.

F. Tighten fasteners to secure reel drive plate to cut-

ting unit.

G. Carefully install spacer (item 12) into grease seal

in LH side plate taking care not to damage seal.

11. Apply antiseize lubricant to end of reel shaft. Position

woodruff key, drive pulley and washer (if equipped) on

reel shaft. Block reel with a piece of wood to prevent it

from turning. Install flange nut that secures pulley to reel

shaft. Torque flange nut from 40 to 50 ft–lb (54 to 68

N–m).

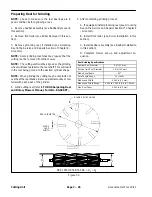

12.Secure grass shield to side plates with removed fas-

teners.

13.Check for free movement of reel assembly by rotat-

ing pulley. If binding is noted, identify and correct prob-

lem before continuing.

14.Install reel drive belt, adjust belt tension and install

belt cover (see Reel Drive Belt and Transmission Cou-

pler Drive Belt Replacement in Service and Repairs sec-

tion of Chapter 4 – Traction and Reel Drive System).

15.If cutting unit is equipped with a groomer, install

grooming reel (see Grooming Reel in the Service and

Repairs section of Chapter 8 – Groomer).

16.Install front and rear rollers (see Roller Installation in

this section).

17.Install bedbar to the cutting unit (see Bedbar Installa-

tion in this section).

18.Complete cutting unit set–up and adjustment se-

quence.

NOTE: The parallel position of the rear roller to the cut-

ting reel is controlled by the precision machined compo-

nents of the assembled cutting unit. If necessary, a

limited amount of adjustment is possible to parallel the

rear roller to the cutting reel (see Leveling Rear Roller

in the Adjustment section of this chapter).

19.Install cutting unit to the traction unit (see Separating

Cutting Unit from Traction Unit in this chapter).

Summary of Contents for 04022 Greensmaster Flex 21

Page 2: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Page 4: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Page 58: ...Greensmaster Flex 18 21 Page 5 10 Electrical System This page is intentionally blank ...

Page 83: ...Greensmaster Flex 18 21 Page 7 13 Cutting Unit This page is intentionally blank Cutting Unit ...

Page 85: ...Greensmaster Flex 18 21 Page 7 15 Cutting Unit This page is intentionally blank Cutting Unit ...

Page 111: ...Greensmaster Flex 18 21 Groomer Page 8 15 This page is intentionally blank Groomer ...