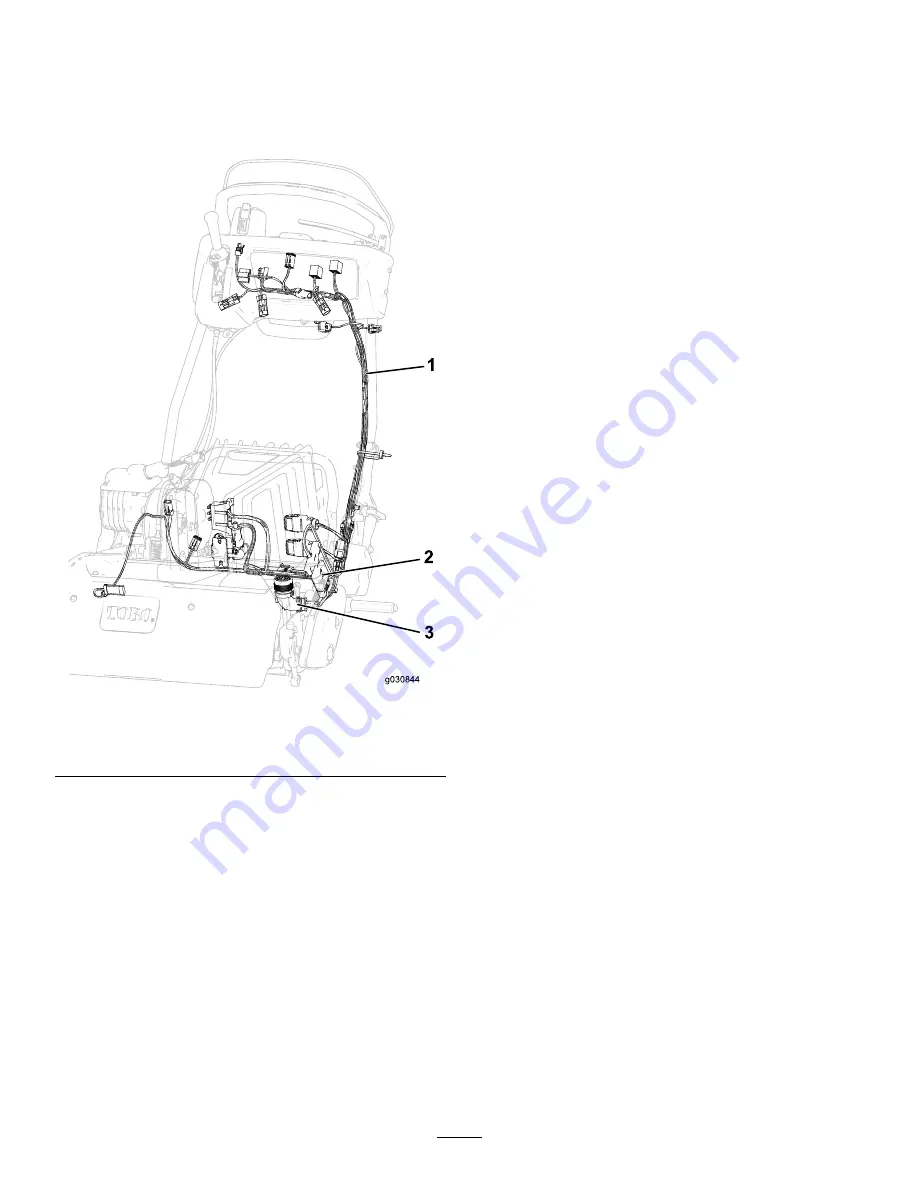

Inspecting the Wire Harnesses

and Component Connector

Assemblies

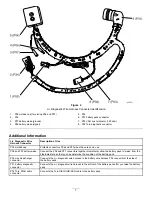

shows the three wire harnesses.

g030844

2

3

1

Figure 19

1.

Main harness

3.

Battery harness

2.

Battery adapter harness

The wire harnesses and electrical components include the

following:

•

Electrical connectors

•

Connector pins

•

Electrical terminals

•

Insulated wire

While you are troubleshooting, inspect the parts for wear

and damage.

Common electrical problems include:

•

Open, shorted, or burned wires

Note:

Debris, such as wet grass clippings, can act as a

conductor.

•

Corroded terminals or pins

•

Water in the connector

•

Connector pins that are loose, bent, or mispositioned

•

Connectors that are not fully seated

•

Wires that are pinched, frayed, or are missing insulation

•

Damaged connector locks, clips, or housings

•

Missing or inadequate dielectric grease

Note:

Dielectric grease is used in all unsealed wire

harness connectors.

Repairing Harness Wire

Insulation

If damage extends through the insulation and strands of the

wire are broken, repair or replace the wire harness. Contact

your Toro Service Representative for guidance when repairing

wires, terminals, pins, and/or connectors.

If there is damage to the outer insulation only, or if the

damage to the shielding is abrasion or deformation only with

no broken strands, repair the wire harness as follows:

1.

Clean the damaged area of the part with isopropyl

alcohol.

2.

Dry the part with a clean lint-free cloth.

3.

Wrap the damaged area with 2 layers of all-weather

electrical tape or an equivalent.

Note:

Ensure that the tape extends past the damage by a

minimum of 1.3 cm (1/2 inch).

Note:

Heatshrink tape properly installed in the same manner

as electrical tape is acceptable. Install the heatshrink tape

according to the manufacturer’s instructions.

Attaching Wire Harnesses

Properly attaching the wire harnesses to the machine helps

keep the connectors from becoming loose and protects the

harnesses from accidental damage caused by vibration.

•

Ensure that no device used to attach a wire harness to the

machine can rotate or slide freely on the wire harness.

•

For wires not contained in convoluted tubing, secure the

wires with electrical tape or a cable tie every 10 to 15 cm

(4 to 6 inches).

•

For split-loom, convoluted tubing, ensure that the tape or

cable ties are 1.3 cm (1/2 inch) away from any connectors

or labels.

13