24

3. Install drain plug; remove oil fill plug (Fig. 31), assure

engine is level and fill crankcase with fresh clean oil;

refer to Engine Operator’s Manual for oil

requirements.

Traction Drive Belt Adjustment

The belt should be tight enough so traction wheels will

spin on cement floor when clutch is engaged with the

engine running. Belt should be checked after first 10 hours

of operation and tightened if necessary. To adjust the belt:

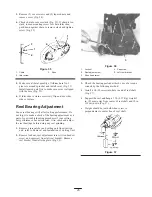

1. Remove belt cover from left side of machine (Fig. 32).

2

1

Figure 32

1.

Cover

2.

Engine mounting fastener

2. Loosen the four engine hold down screws.

3. Slide engine rearward equally on both sides until belt

is tight. Tighten mounting fasteners and check

adjustment by placing unit on a cement floor, starting

engine and checking to see if traction wheels spin

when clutch is engaged.

4. Continue adjustment until tension is correct and install

belt guard (Fig. 32).

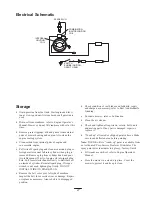

Clutch Adjustment

Should clutch slip during operation, check and adjust as

follows:

Do not adjust clutch with the engine running.

Clutch could catch and cause harm to both

you and machine.

Warning

1. Tighten clutch locknut in small increments, start

engine and test adjustment (Fig. 33).

2. Traction wheels will spin, on a cement floor, when

clutch is engaged.

1

2

Figure 33

1.

Locknut

2.

Clutch friction discs

3. Repeat adjustment until clutch operates correctly.

Important

Mower should remain stationary when

engine is running and clutch is in the disengaged position.

Note: Clutch plates and friction discs should be totally

free of grease or oil (Fig. 33).

Cutting Unit Chain Adjustment

Once each year, check the chain assembly inside the

cutting unit chain case. Use the following procedures:

1. Remove the grass catcher and cutting unit from the

traction unit; refer to Removal and Installation of

Cutting Unit.

2. Remove Allen head set screw anchoring steel shaft to

cover (Fig. 34).

2

1

3

Figure 34

1.

Chain case

2.

Allen head set screw

3.

Tapered nuts