15

1

1

2

3

3

Figure 12

1.

Cutting unit pivot arms

2.

Traction unit frame tube

3.

Capscrews

5. Rotate pivot arms forward (Fig. 12) and rest traction

unit on restrained kickstand.

6. Pull cutting unit forward about 2 in. (51 mm) and then

to the right to disengage the transmission coupling

(Fig. 12).

1

Figure 13

1.

Transmission coupling

2.

7. Reverse procedure to install cutting unit.

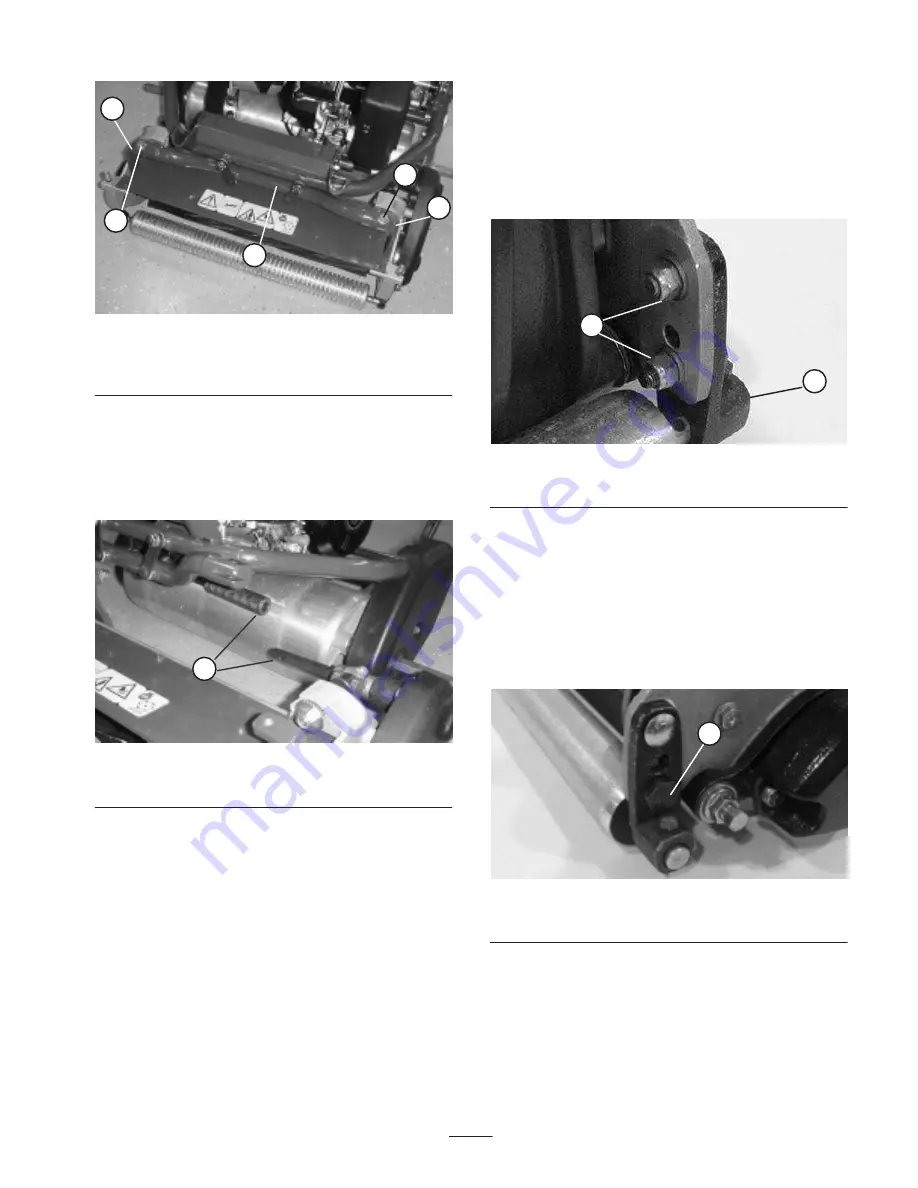

Leveling the Rear Roller to the

Reel

1. Position cutting unit on a flat, level surface preferably

a precision ground surface plate.

2. Place a 1/4 in. (6.4 mm) or thicker plate under the reel

blades and against front edge of bedknife.

Note: Be sure the plate covers the full length of the reel

blades and three blades contact.

3. Firmly press down on cutting unit and maintain

pressure on rear roller. Try inserting a piece of paper

under each end of the roller. If the gap is greater than

the piece of paper, on either end, an adjustment may

be required, proceed to step 4.

4. Loosen locknuts securing right rear roller bracket to

cutting unit sideplate (Fig. 14).

1

2

Figure 14

1.

Right rear roller bracket

2.

Locknuts

5. While holding reel securely on plate and maintaining

pressure on rear roller, rotate lower right roller

mounting bolt (Fig. 15). This mounting bolt has an

offset, which when rotated, acts as an eccentric (cam)

to raise or lower the roller. There is an I.D. dot which

denotes the offset of the bolt. Dot indicates in which

direction right end of roller moves when bolt is turned

and should always be in the rear half of the arc as

shown in figure 15.

1

Figure 15

1.

Eccentric bolt

Note: If additional adjustment is required, replace the

screw on the left-hand bracket with another eccentric bolt,

Part No. 105–3833. Ensure both rear roller brackets are in

the same hole.

6. To verify if roller is level, try inserting a piece of

paper under each end of roller.