25

1

2

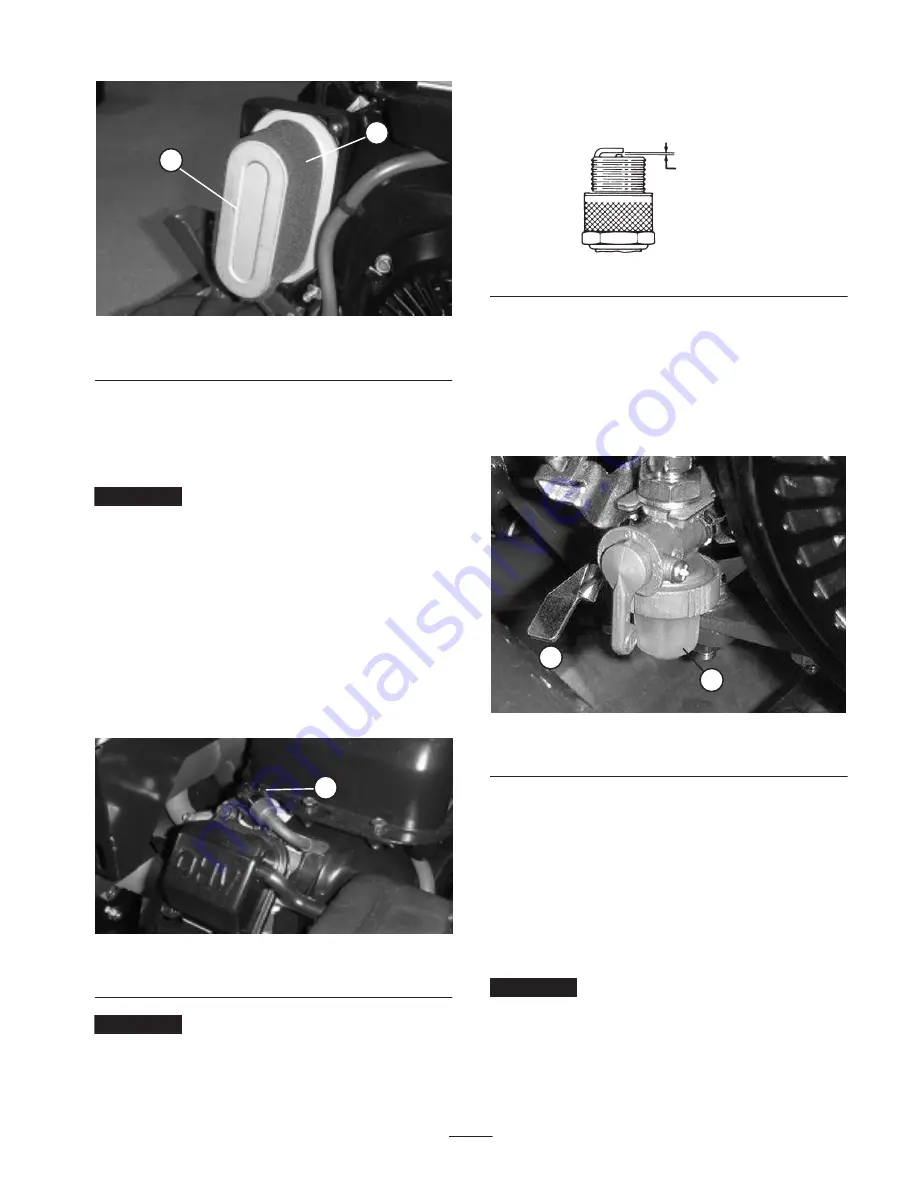

Figure 31

1.

Foam element

2.

Paper element

4. When servicing foam element, check condition of

paper element. Clean or replace as required.

5. Install foam element, paper element, and air cleaner

cover.

Important

Do not operate the engine without the air

cleaner element because extreme engine wear and damage

will likely result.

Replacing the Spark Plug

Use an NGK BPR 5ES spark plug or equivalent. Correct

air gap is 0.028–0.032 in. Remove plug after every 100

operating hours and check its condition.

1. Pull wire off spark plug (Fig. 32).

2. Clean around spark plug and remove plug from

cylinder head.

1

Figure 32

1.

Spark plug wire

Important

Replace a cracked, fouled, or dirty spark

plug. Do not sand blast, scrape, or clean electrodes

because engine damaged could result from grit entering

the cylinder.

3. Set air gap at 0.028–0.032 in. (Fig. 33). Install

correctly gapped spark plug and tighten firmly to

17 ft.-lb.

0.028-0.032 in.

Figure 33

Cleaning the Fuel Filter

Initially, clean fuel filter after the first 20 hours of

operation; thereafter clean after every 50 hours operation.

1. Close fuel shut off valve and unscrew bowl from filter

body (Fig. 34).

2

1

Figure 34

1.

Shut-off valve

2.

Bowl

2. Clean bowl and filter in clean gasoline and install.

Changing the Transmission

Fluid

The fluid level in the transmission should be checked at

50 hour intervals; refer to Checking the Transmission

Fluid, page 14. Change the transmission fluid after the

first 50 hours of operation and every 2 years thereafter.

Important

Use only Dexron lll or equivalent

transmission fluids. Other fluids could cause system

damage.

1. Place a drain pan at the rear of the machine.