1

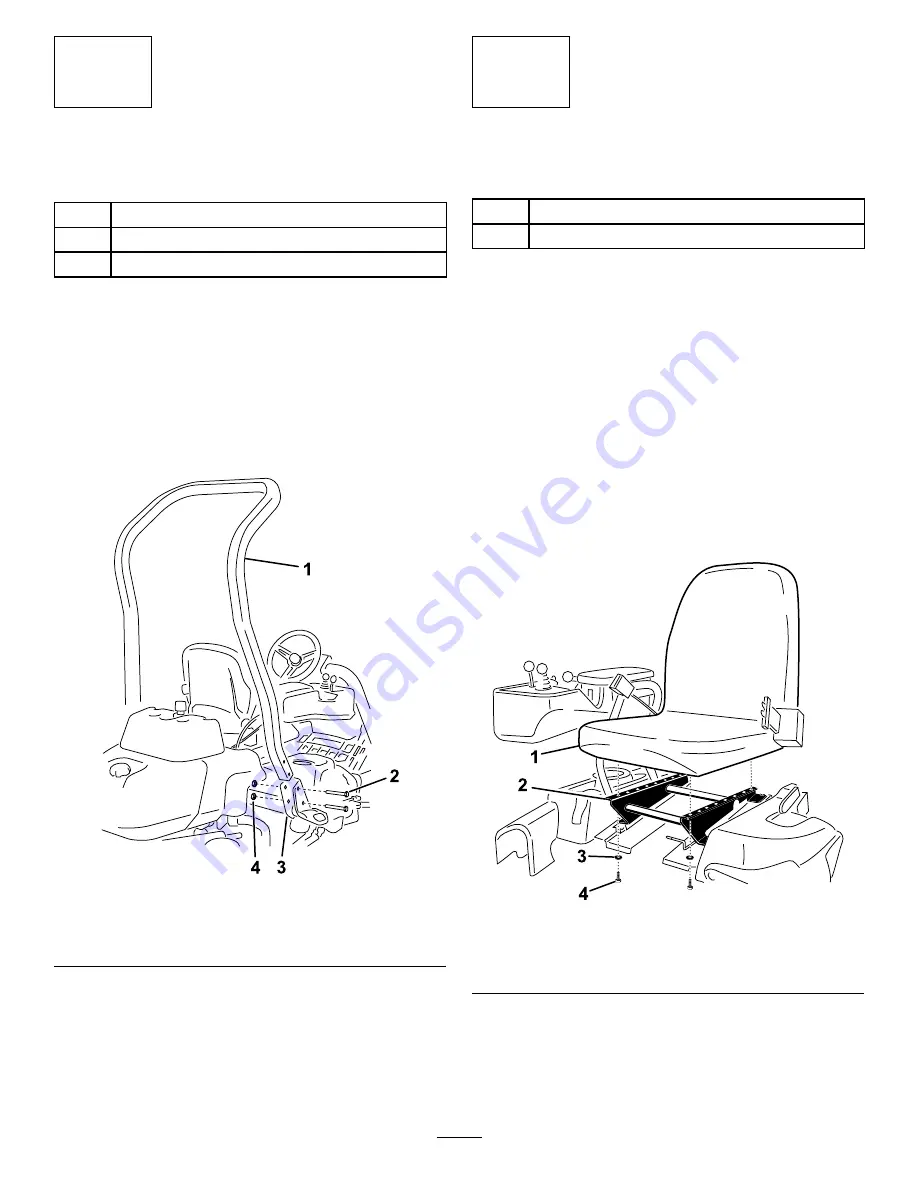

Installing the Roll Bar

Parts needed for this procedure:

1

Roll bar

4

Bolt (1/2 x 3-3/4 inches)

4

Flange nut (1/2 inch)

Procedure

1.

Remove the top crate support from the crate.

2.

Remove the roll bar from the crate.

3.

Use 4 bolts (1/2 x 3-3/4 inches) and 4 flange

nuts (1/2 inch) to install the roll bar into the

ROPS brackets on each side of the machine as

shown in

.

g233739

Figure 3

1.

Roll bar

3.

ROPS bracket

2.

Bolt (1/2 x 3-3/4 inches)

4.

Flange nut (1/2 inch)

4.

Torque the fasteners to 136 to 149 N∙m (100 to

110 ft-lb).

2

Installing the Seat

Parts needed for this procedure:

1

Seat

1

Seat wire harness

Procedure

Note:

Mount the seat in the front set of mounting

holes to gain an additional 7.6 cm (3 inches) in the

forward adjustment, or in the rear mounting holes

for an additional 7.6 cm (3 inches) in the rearward

adjustment.

1.

Remove and discard the lag bolts securing the

seat slides and cut the shipping straps.

2.

Remove the 4 bolts (5/16 x 3/4 inch) and

washers from the shipping bracket and discard

the bracket.

3.

Secure the seat to the seat base with 4 bolts

and washers removed previously (

).

g193736

Figure 4

1.

Seat

3.

Washer

2.

Seat base

4.

Bolt (5/16 x 3/4 inch)

4.

Locate the open connector on the main wiring

harness to the right of the seat and connect it to

the wire harness that came with the seat.

5.

Route the seat wiring harness around the seat

slides, ensuring that it is not pinched when the

10