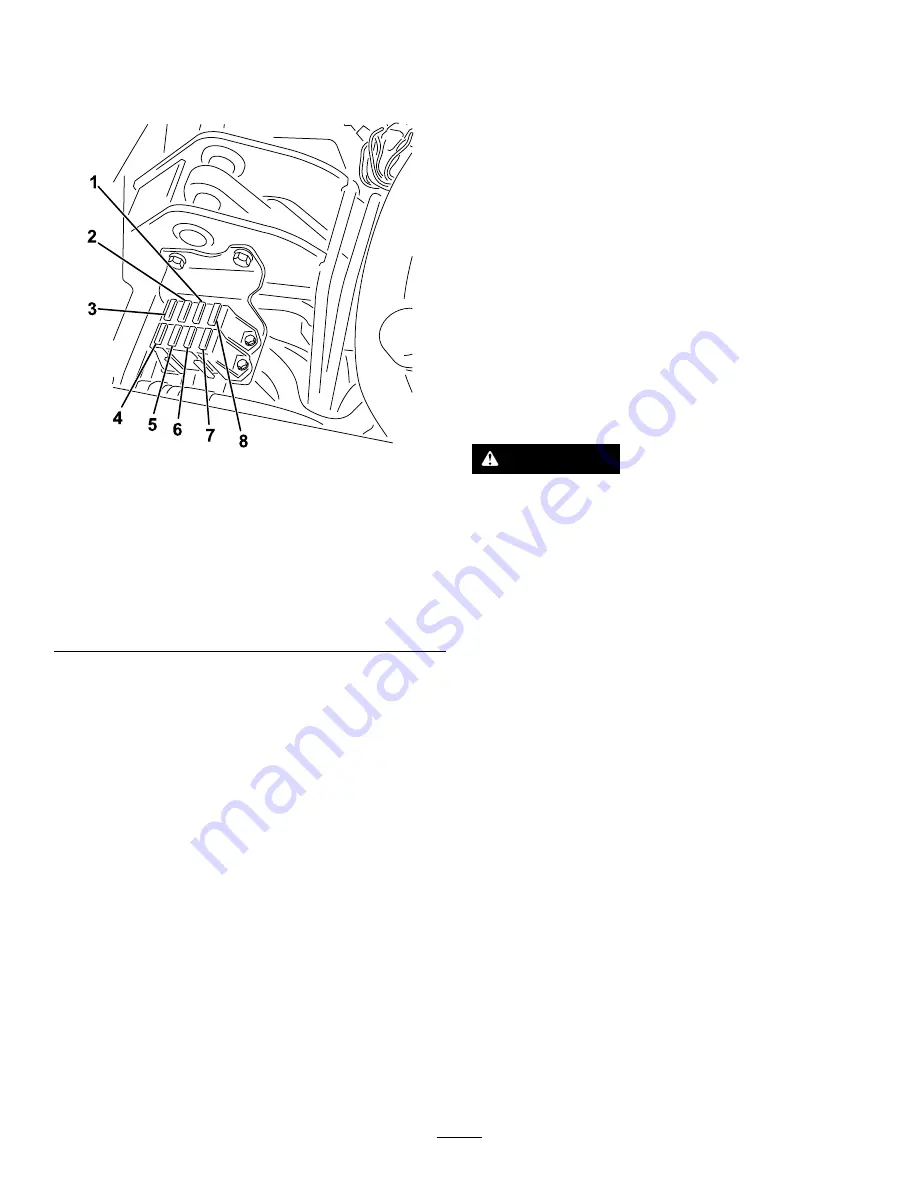

Locating the Fuses

The fuses in the electrical system are located under

the seat (

).

g195277

Figure 32

1.

Start/run, Diagnostic

lights, and leak

detector—7.5 A

5.

No fuse

2.

Reel engage and

lift/lower—7.5 A

6.

Lights and leak

detector—15 A

3.

Lift reel and E-reel

enable—7.5 A

7.

Run—10 A

4.

Hydraulic fan kit

(optional)—15 A

8.

ECM logic and power—2

A

Drive System

Maintenance

Checking the Tire Pressure

Service Interval:

Before each use or daily

Vary the tire pressure for all 3 wheels, depending

upon your turf conditions, from a minimum of 83 to a

maximum of 110 kPa (12 psi to 16 psi).

Checking the Torque of the

Wheel Nuts

Service Interval:

After the first hour

After the first 10 hours

Every 200 hours

WARNING

Failure to maintain proper torque of the wheel

nuts could result in personal injury.

Torque the wheel nuts to the specified torque

at the specified intervals.

Wheel nut torque specification:

95 to 122 N∙m (70

to 90 ft-lb)

Note:

To ensure even distribution, torque the wheel

nuts in a X pattern.

Adjusting the Transmission

for Neutral

If the machine creeps when the traction-control pedal

is in the N

EUTRAL

position, adjust the neutral-return

mechanism.

1.

Ensure that the bypass valve is closed.

2.

Lift the machine and support it at the frame so

that 1 of the front wheels is off the floor.

Note:

If machine is equipped with a 3-Wheel

Drive Kit, also raise and block rear wheel.

3.

Start the engine, move the throttle to the S

LOW

position, and ensure that the front wheel that is

off the floor is not rotating.

4.

If the wheel is rotating, shut off the engine and

proceed as follows:

A.

Loosen the nut securing the eccentric to the

top of the hydrostat (

34