Checking the

Reel-to-Bedknife Contact

Each day before operating the machine, check the

reel-to-bedknife contact, regardless if the quality of cut

had previously been acceptable. There must be light

contact across the full length of the reel and bedknife;

refer to the Cutting Unit

Operator’s Manual

.

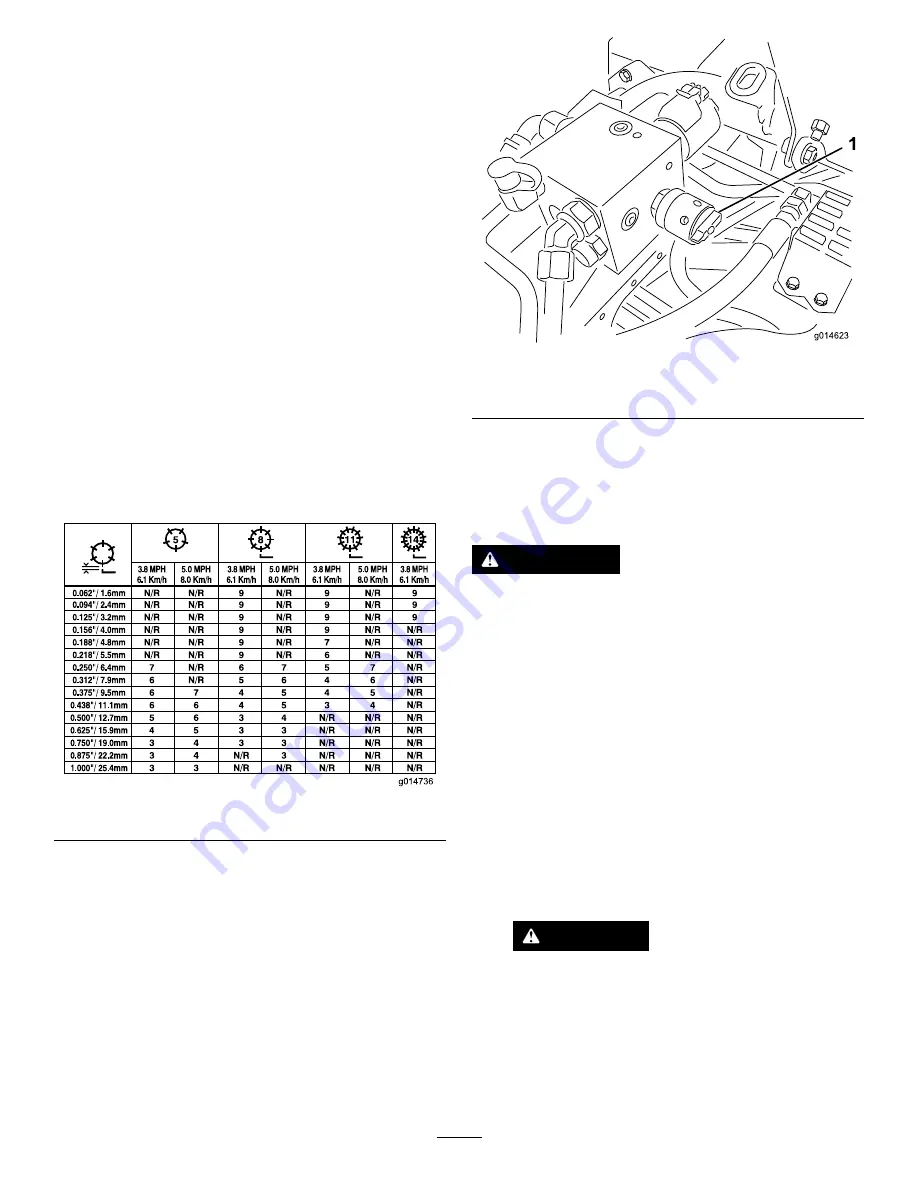

Setting the Reel Speed

To achieve a consistent, high-quality cut and a

uniform, after-cut appearance, you must correctly set

the reel speed control (located on the manifold block

under the cover to the left of the seat). Adjust the reel

speed control as follows:

1.

Select the height-of-cut at which the cutting units

are set.

2.

Choose the desired ground speed best suited

for conditions.

3.

Use the table that follows to determine the

reel-speed setting for your 5-, 8-, 11-, or

14-blade cutting units. (

)

g014736

Figure 50

4.

Adjust the reel speed by rotating the knob

(

) until the indicator arrows are in line

with the number you determined in step

g014623

Figure 51

1.

Reel-speed control

Note:

You can increase or decrease the reel

speed to compensate for turf conditions.

Backlapping the Reels

WARNING

Contact with the reels or other moving parts

can result in personal injury.

•

Keep your fingers, hands, and clothing

away from the reels or other moving parts.

•

Never attempt to turn the reels by hand or

foot while the engine is running.

1.

Position the machine on a level surface, lower

the cutting units, shut off the engine, and engage

the parking brake.

2.

Remove the plastic cover to the left side of the

seat.

3.

Make initial reel to bedknife adjustments

appropriate for backlapping on all cutting units

which are to be backlapped; refer to the Cutting

Unit

Operator’s Manual

.

DANGER

Changing the engine speed while

backlapping may cause the reels to stall.

•

Never change the engine speed while

backlapping.

•

Backlap only at idle engine speed.

4.

Start the engine and run at low idle speed.

44