Greensmaster 3300/3400

Hydraulic System

Page 5 -- 87

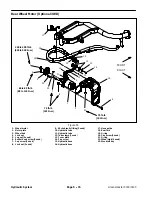

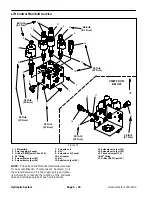

Removal (Fig. 63)

1. Park machine on a level surface, engage parking

brake, lower cutting units and stop the engine.

2. Remove left side cover next to operator seat to allow

access to mow control manifold.

CAUTION

Before continuing further, read and become fa-

miliar with General Precautions for Removing

and Installing Hydraulic System Components in

this section.

3. Thoroughly clean hydraulic hose ends and fittings on

mow control manifold to prevent hydraulic system con-

tamination.

4. Label all hydraulic and electrical connections for as-

sembly purposes.

5. Disconnect wire harness connectors from solenoid

valve and backlap switch.

IMPORTANT: Before disconnecting hydraulic lines

from the manifold fittings, make sure each hose is

labeled to ensure it can be connected to the correct

manifold fitting/port.

6. Disconnect hose and tube assemblies and remove

their respective O--rings from the hydraulic fittings. Al-

low hoses and tubes to drain into a suitable container.

Cap or plug hoses and manifold fittings to prevent con-

tamination.

7. Remove two (2) flange head screws (item 7) that se-

cure manifold to machine frame. Remove manifold as-

sembly from the machine.

IMPORTANT: Before removing any hydraulic fit-

tings from the hydraulic manifold, make sure the

position of each fitting is observed and recorded to

ensure proper fitting installation.

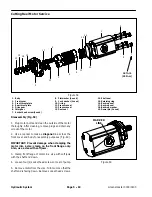

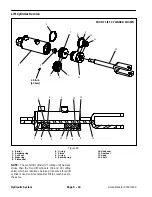

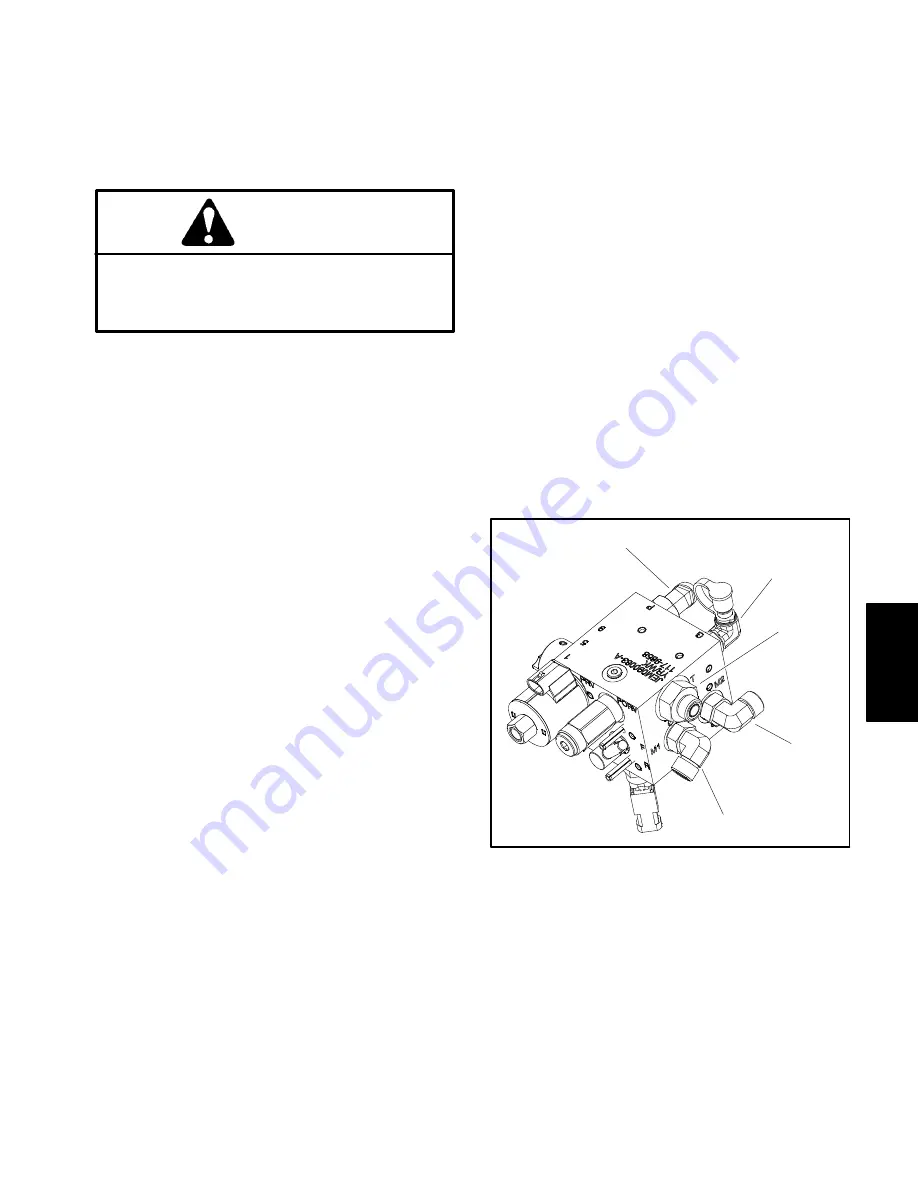

8. If hydraulic fittings are to be removed from manifold,

mark fitting orientation to allow correct assembly. Re-

move hydraulic fittings and O--rings from manifold (Fig.

64). Discard removed O--rings.

Installation (Fig. 63)

1. If fittings were removed from manifold, lubricate and

place new O--rings onto fittings. Install fittings into man-

ifold openings making sure that fitting orientation is as

noted during removal (Fig. 64). Properly tighten fittings

(see Hydraulic Fitting Installation in the General Infor-

mation section of this chapter).

2. Position manifold assembly to the machine frame.

Secure assembly to the frame with two (2) flange head

screws (item 7).

3. Remove caps and plugs from disconnected hydrau-

lic lines and manifold fittings.

4. Lubricate and position new O--rings to fittings on

manifold. Use labels placed during the removal process

to properly install hydraulic lines to manifold fittings (see

Hydraulic Hose and Tube Installation in the General In-

formation section of this chapter).

5. Connect wire harness connectors to solenoid valve

and backlap switch.

6. Install left side cover.

1. 45

o

fitting

2. Test fitting

3. Adapter fitting (port T)

4. 90

o

fitting (port M2)

5. 90

o

fitting (port M1)

Figure 64

1

2

3

4

5

Hydraulic System

Summary of Contents for 04510 Greensmaster 3300 TriFlex

Page 2: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 4: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 6: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 24: ...Greensmaster 3300 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3400 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3300 3400 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 170: ...Greensmaster 3300 3400 Hydraulic System Page 5 118 This page is intentionally blank ...

Page 172: ...Greensmaster 3300 3400 Page 6 2 Electrical System This page is intentionally blank ...

Page 230: ...Greensmaster 3300 3400 Page 6 60 Electrical System This page is intentionally blank ...

Page 303: ...Greensmaster 3300 3400 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 318: ...Greensmaster 3300 3400 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 332: ...Page 10 16 This page is intentionally blank ...