Greensmaster 3300/3400

Hydraulic System

Page 5 -- 107

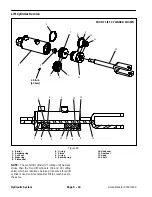

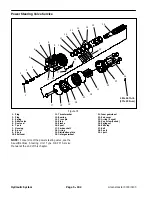

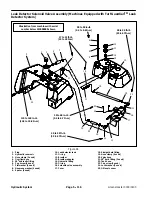

Disassembly (Fig. 77)

1. Pump oil out of cylinder into a drain pan by slowly

moving shaft in and out of cylinder bore. Plug ports and

clean outside of cylinder.

IMPORTANT: To prevent damage when clamping

cylinder barrel in a vise, clamp only on ball joint

location. Do not clamp the vise jaws against the cyl-

inder barrel or shaft surface.

2. Mount cylinder in a vise by clamping vise on barrel

ball joint location of cylinder. Use of a vise with soft jaws

is recommended.

3. Using a pipe wrench, carefully remove both collars

(item 2) from cylinder barrel.

4. Carefully remove non--ball joint end head (item 13)

from end of barrel.

5. Grasp end of shaft and use a twisting and pulling mo-

tion to carefully extract shaft assembly (with collar, ball

joint end head and piston) from cylinder barrel.

6. Remove wear ring from piston to allow access to

dowel pin (item 9) that secures piston to shaft.

7. Use press to carefully remove dowel pin (item 9) from

piston and shaft.

8. Slide piston (item 10), ball joint end head (item 3) and

collar (item 2) from shaft.

9. Remove and discard seals, back--up rings, wear

rings and O--rings from piston and both heads.

CAUTION

Use eye protection such as goggles when using

compressed air to dry cylinder parts.

10.Wash cylinder parts in clean solvent. Dry parts with

compressed air. Do not wipe parts dry with paper or cloth

towels. Lint from towels in a hydraulic system will cause

damage.

11.Carefully inspect internal surface of barrel for dam-

age (deep scratches, out--of--round, etc). Inspect shaft,

both heads and piston for evidence of excessive scor-

ing, pitting or wear. Replace entire steering cylinder if in-

ternal components are damaged.

Assembly (Fig. 77)

1. Put a coating of clean hydraulic oil on all new seals,

back--up rings, wear rings and O--rings.

2. Install new shaft seal, dust seal, back up ring and O--

ring onto both heads (items 3 and 13).

3. Install piston seal and O--ring to the piston (item 10).

Also, install one (1) wear ring onto piston in groove that

does not contain hole for dowel pin. Second wear ring

will be installed after piston is secured to shaft.

4. Carefully slide collar (item 2), ball joint end head

(item 3), second piston wear ring and piston (item 10)

onto shaft taking care to not damage seals. Make sure

that hole in piston for dowel pin is orientated toward ball

joint end of shaft.

5. Align holes in piston and shaft. Use press to install

dowel pin (item 9) into piston and shaft. Make sure that

dowel pin ends do not extend into the piston wear ring

location.

6. Install second wear ring into piston groove that con-

tains hole for dowel pin.

7. Coat all internal cylinder parts with a light coat of

clean hydraulic oil. Carefully slide shaft assembly (with

collar, ball joint end head and piston) into the barrel be-

ing careful to not damage seals.

8. Lubricate non--ball joint end head (item 13) assem-

bly with clean hydraulic oil and carefully slide it onto

shaft and into barrel.

9. Using a pipe wrench, install collars to secure both

heads in cylinder barrel.

Summary of Contents for 04510 Greensmaster 3300 TriFlex

Page 2: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 4: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 6: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 24: ...Greensmaster 3300 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3400 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3300 3400 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 170: ...Greensmaster 3300 3400 Hydraulic System Page 5 118 This page is intentionally blank ...

Page 172: ...Greensmaster 3300 3400 Page 6 2 Electrical System This page is intentionally blank ...

Page 230: ...Greensmaster 3300 3400 Page 6 60 Electrical System This page is intentionally blank ...

Page 303: ...Greensmaster 3300 3400 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 318: ...Greensmaster 3300 3400 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 332: ...Page 10 16 This page is intentionally blank ...