Greensmaster 3300/3400

Hydraulic System

Page 5 -- 109

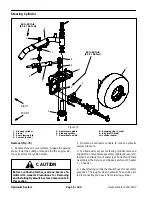

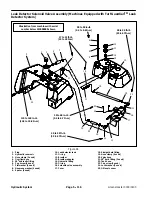

Removing Hydraulic Reservoir (Fig. 78)

1. Park machine on a level surface, set brake, lower

cutting units and stop engine. Remove key from the igni-

tion switch.

CAUTION

Before continuing further, read and become fa-

miliar with General Precautions for Removing

and Installing Hydraulic System Components in

this section.

2. Disconnect oil level sensor wire connector from ma-

chine wire harness.

3. Remove leak detector tank (see Leak Detector Tank

Removal in this section).

4. Remove leak detector solenoid valve assembly from

hydraulic reservoir (see Leak Detector Solenoid Valve

Assembly in this section).

5. Completely drain hydraulic oil from hydraulic reser-

voir through gear pump inlet (suction) hose into a suit-

able container.

6. Label hydraulic reservoir hoses for assembly pur-

poses. Thoroughly clean hydraulic hose ends prior to

disconnecting the hoses from reservoir fittings.

7. Remove hose assemblies and O--rings from reser-

voir fittings. Allow hoses to drain into suitable container.

8. Put clean caps or plugs on disconnected hoses and

fittings to prevent contamination.

9. To allow easier access to fasteners that secure hy-

draulic reservoir, raise and support tank mount plate as-

sembly (hydraulic reservoir, fuel tank and tank mount

plate) (see Tank Mount Plate Assembly in the Service

and Repairs section of Chapter 7 -- Chassis).

10.Remove four (4) cap screws (item 17), flat washers

(item 16) and flange bushings (item 15) that secure the

hydraulic reservoir (item 2) to the tank mount plate.

11.Remove hydraulic reservoir from machine.

12.If hydraulic fittings are to be removed from reservoir,

mark fitting orientation to allow correct assembly. Re-

move hydraulic fittings from hydraulic reservoir as need-

ed. Discard O--rings from removed fittings.

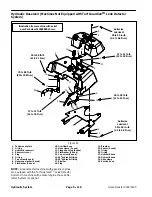

13.Remove oil level sensor (item 11) from hydraulic res-

ervoir. Discard O--ring from sensor.

14.Clean hydraulic reservoir and reservoir components

with clean solvent. Inspect reservoir for leaks, cracks or

other damage.

Installing Hydraulic Reservoir (Fig. 78)

1. Lubricate and place new O--rings onto all removed

fittings. Install fittings into reservoir openings. Use

marks made during the removal process to correctly

orientate fittings. Refer to Figure 78 for reservoir fitting

installation torque specifications.

2. Install oil level sensor into reservoir making sure that

arrow on sensor is pointing down (Fig. 79). Torque sen-

sor nut from

110 to 140 in--lb (12.5 to 15.8 N--m)

.

3. Position hydraulic reservoir onto tank mount plate.

4. Apply antiseize lubricant to threads of four (4) cap

screws (item 17). Secure hydraulic reservoir to the tank

mount plate with four (4) cap screws, flat washers (item

16) and flange bushings (item 15). Torque cap screws

from

30 to 50 in--lb (3.4 to 5.6 N--m)

.

5. Lower and secure tank mount plate assembly (hy-

draulic reservoir, fuel tank and tank mount plate) (see

Tank Mount Plate Assembly in the Service and Repairs

section of Chapter 7 -- Chassis).

6. Remove caps and plugs from disconnected hydrau-

lic hoses and reservoir fittings.

7. Lubricate and position new O--rings to fittings on res-

ervoir. Use labels placed during the removal process to

properly install hydraulic lines to reservoir fittings (see

Hydraulic Hose and Tube Installation in the General In-

formation section of this chapter).

8. Install leak detector solenoid valve assembly to hy-

draulic reservoir (see Leak Detector Solenoid Valve As-

sembly in this section).

9. Install leak detector tank (see Leak Detector Tank

Installation in this section).

10.Connect oil level sensor wire connector to machine

wire harness.

11.Fill hydraulic reservoir with new hydraulic oil.

12.Verify leak detector operation.

1. Oil level sensor

2. Sensor arrow

Figure 79

1

2

Hydraulic System

Summary of Contents for 04510 Greensmaster 3300 TriFlex

Page 2: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 4: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 6: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 24: ...Greensmaster 3300 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3400 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3300 3400 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 170: ...Greensmaster 3300 3400 Hydraulic System Page 5 118 This page is intentionally blank ...

Page 172: ...Greensmaster 3300 3400 Page 6 2 Electrical System This page is intentionally blank ...

Page 230: ...Greensmaster 3300 3400 Page 6 60 Electrical System This page is intentionally blank ...

Page 303: ...Greensmaster 3300 3400 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 318: ...Greensmaster 3300 3400 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 332: ...Page 10 16 This page is intentionally blank ...