Greensmaster 3300/3400

Page 6 -- 34

Electrical System

Fusible Links

The electrical system on TriFlex Greensmaster ma-

chines include a harness with three (3) fusible links for

machine circuit protection. This fusible link harness con-

nects the machine wire harness to the positive (+) bat-

tery terminal.

Greensmaster 3300 machines (gasoline engine) use

only two (2) of the harness fusible links. The fusible link

harness on Greensmaster 3300 machines is connected

to the starter solenoid (Fig. 37).

Greensmaster 3400 machines (diesel engine) use all

three (3) of the harness fusible links. The fusible link har-

ness on Greensmaster 3400 machines is connected to

the starter B+ terminal (Fig. 38). Greensmaster 3400

machines use an additional fusible link that is included

in the wire harness and connects the starter G terminal

to the engine run solenoid pull coil.

If any of these links should fail, current to the protected

circuit will cease. Refer to the electrical schematic and

wire harness drawings in Chapter 10 -- Foldout Draw-

ings for additional circuit information.

Testing

Make sure that ignition switch is OFF. Disconnect nega-

tive (--) battery cable from battery terminal and then dis-

connect positive (+) cable from battery (see Battery

Service in the Service and Repairs section of this chap-

ter). Locate fusible link harness and unplug fusible link

connector from wire harness. Use a multimeter to make

sure that continuity exists between the fusible link termi-

nals. If a fusible link is open, replace the fusible link har-

ness.

After testing is complete, make sure that fusible link is

securely attached to engine component and wire har-

ness. Connect positive battery cable to battery terminal

first and then connect negative cable to battery.

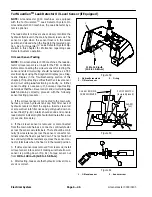

1. Starter solenoid

2. Fusible link harness

3. Harness connector

Figure 37

1

3

2

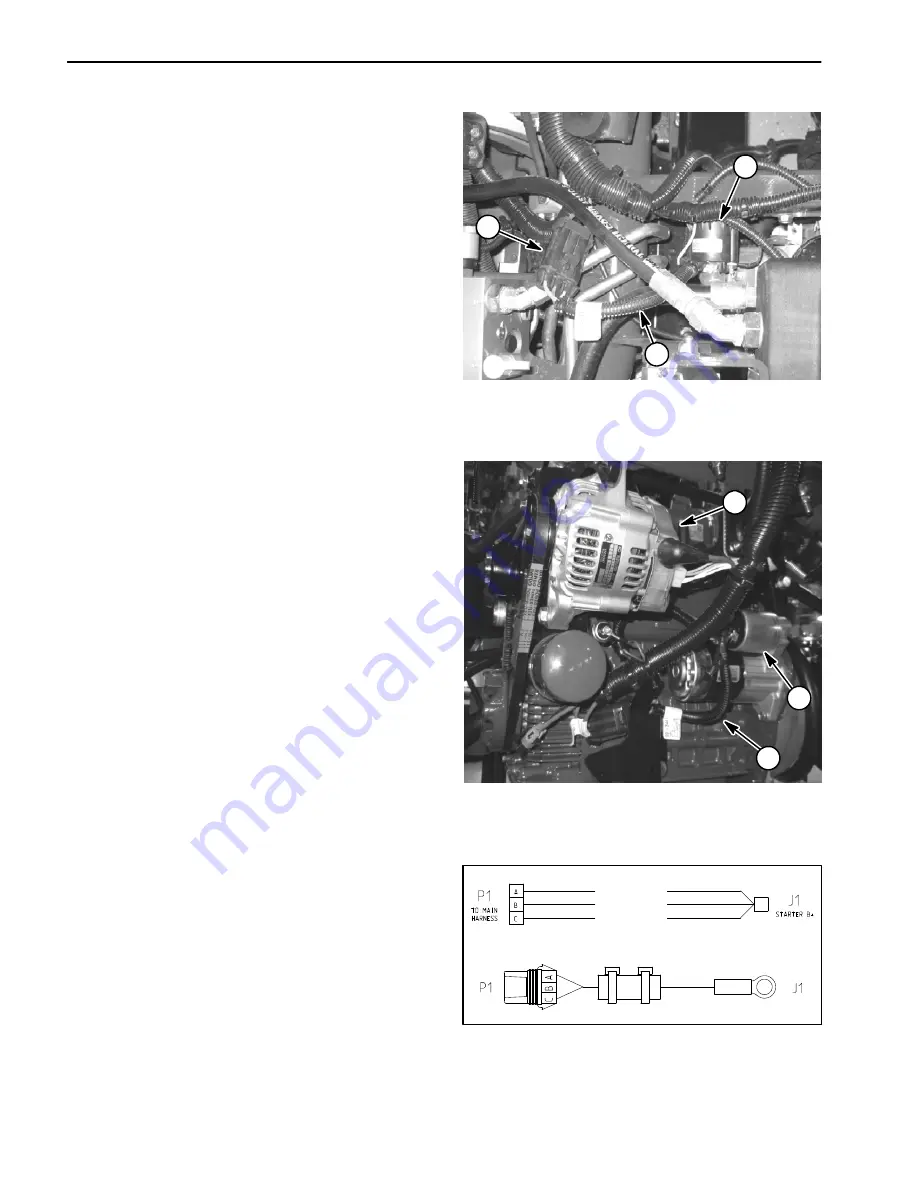

1. Starter solenoid

2. Alternator

3. Fusible link harness

Figure 38

1

3

2

Figure 39

FUSIBLE LINK

FUSIBLE LINK

FUSIBLE LINK

Summary of Contents for 04510 Greensmaster 3300 TriFlex

Page 2: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 4: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 6: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 24: ...Greensmaster 3300 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3400 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3300 3400 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 170: ...Greensmaster 3300 3400 Hydraulic System Page 5 118 This page is intentionally blank ...

Page 172: ...Greensmaster 3300 3400 Page 6 2 Electrical System This page is intentionally blank ...

Page 230: ...Greensmaster 3300 3400 Page 6 60 Electrical System This page is intentionally blank ...

Page 303: ...Greensmaster 3300 3400 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 318: ...Greensmaster 3300 3400 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 332: ...Page 10 16 This page is intentionally blank ...