Greensmaster 3300/3400

Page 6 -- 58

Electrical System

Battery Testing

1. Conduct a hydrometer test of the battery electrolyte.

IMPORTANT: Make sure the area around the cells is

clean before opening the battery caps.

A. Measure the specific gravity of each cell with a

hydrometer. Draw electrolyte in and out of the

hydrometer barrel prior to taking a reading to warm--

up the hydrometer. At the same time take the tem-

perature of the cell.

B. Temperature correct each cell reading. For each

10

o

F (6

o

C) above 80

o

F (27

o

C) add 0.004 to the spe-

cific gravity reading. For each 10

o

F (6

o

C) below 80

o

F

(27

o

C) subtract 0.004 from the specific gravity read-

ing.

Example: Cell Temperature 100

o

F

Cell Gravity

1.245

ADD (20

o

above 80

o

F)

0.008

Correction to 80

o

F

1.253

C. If the difference between the highest and lowest

cell specific gravity is 0.050 or greater or the lowest

cell specific gravity is less than 1.225, charge the bat-

tery. Charge at the recommended rate and time giv-

en in

Battery Charging

or until all cells specific

gravity is 1.225 or greater with the difference in spe-

cific gravity between the highest and lowest cell less

than 0.050. If these charging conditions can not be

met, replace the battery.

2. Perform a high--discharge test with an adjustable

load tester.

This is one of the most reliable means of testing a battery

as it simulates the cold--cranking test. A commercial bat-

tery load tester is

required

to perform this test.

CAUTION

Follow the battery load tester manufacturer’s

instructions when using a load tester.

A. Check the voltage across the battery terminals

prior to testing the battery. If the voltage is less than

12.0 VDC, recharge the battery.

B. If the battery has been charged, apply a 150 amp

load for fifteen (15) seconds to remove the surface

charge. Use a battery load tester following the

manufacturer’s instructions.

C. Make sure the battery terminals are free of corro-

sion.

D. Measure the temperature of the center cell.

E. Connect a battery load tester to the battery termi-

nals

following the manufacturer’s instruction

s.

Connect a digital multimeter to the battery terminals.

F. Apply a test load of 150 amps (one half the crank-

ing performance rating of the battery) for fifteen (15)

seconds.

G. Take a battery voltage reading after fifteen (15)

seconds, then remove the load.

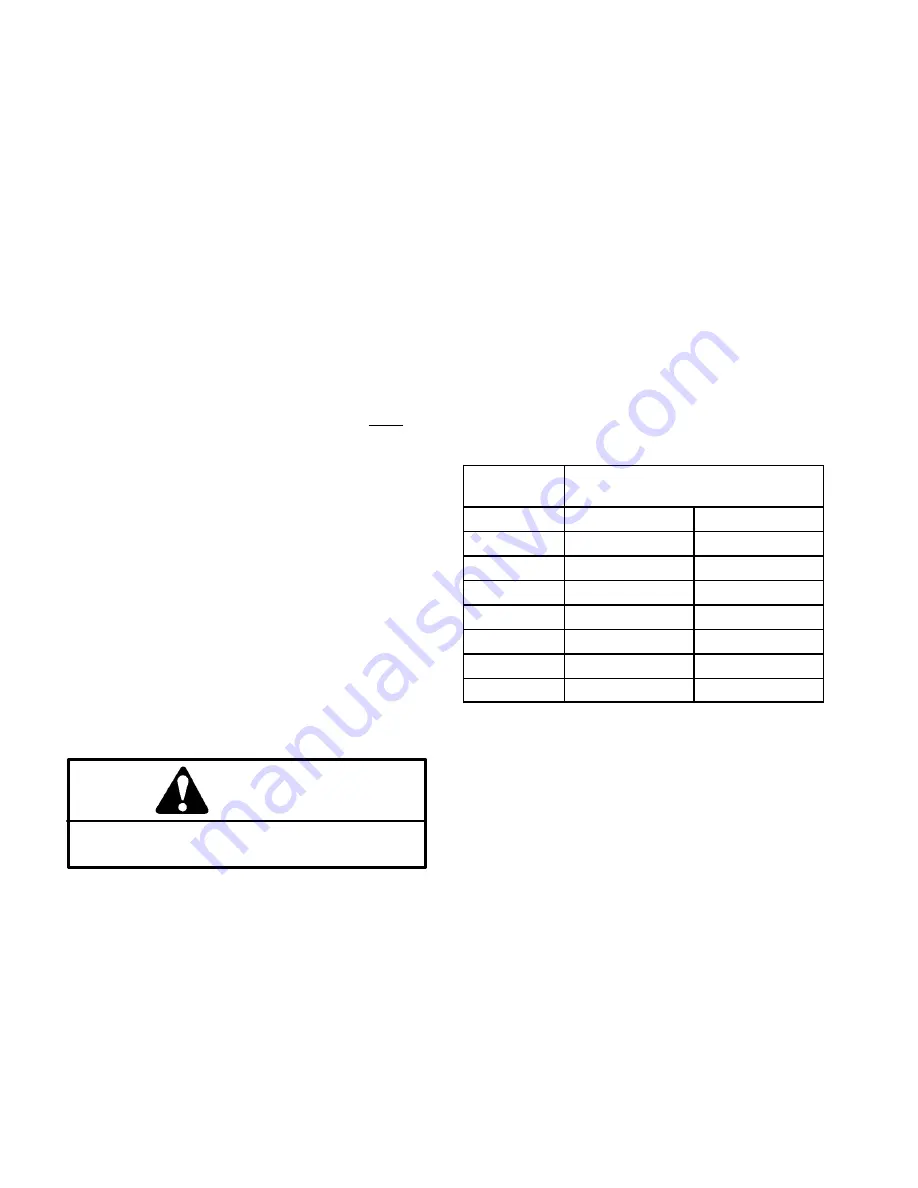

H. Using the table below, determine the minimum

voltage for the center cell temperature reading.

Minimum

Voltage

Battery Electrolyte

Temperature

9.6

70

o

F (and up)

21

o

C (and up)

9.5

60

o

F

16

o

C

9.4

50

o

F

10

o

C

9.3

40

o

F

4

o

C

9.1

30

o

F

--1

o

C

8.9

20

o

F

--7

o

C

8.7

10

o

F

--12

o

C

8.5

0

o

F

--18

o

C

I. If the test voltage is below the minimum voltage

listed in the table, replace the battery. If the test volt-

age is at or above the minimum, return the battery to

service.

Summary of Contents for 04510 Greensmaster 3300 TriFlex

Page 2: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 4: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 6: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 24: ...Greensmaster 3300 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3400 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3300 3400 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 170: ...Greensmaster 3300 3400 Hydraulic System Page 5 118 This page is intentionally blank ...

Page 172: ...Greensmaster 3300 3400 Page 6 2 Electrical System This page is intentionally blank ...

Page 230: ...Greensmaster 3300 3400 Page 6 60 Electrical System This page is intentionally blank ...

Page 303: ...Greensmaster 3300 3400 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 318: ...Greensmaster 3300 3400 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 332: ...Page 10 16 This page is intentionally blank ...