Greensmaster 3300/3400

Groomer

Page 9 -- 17

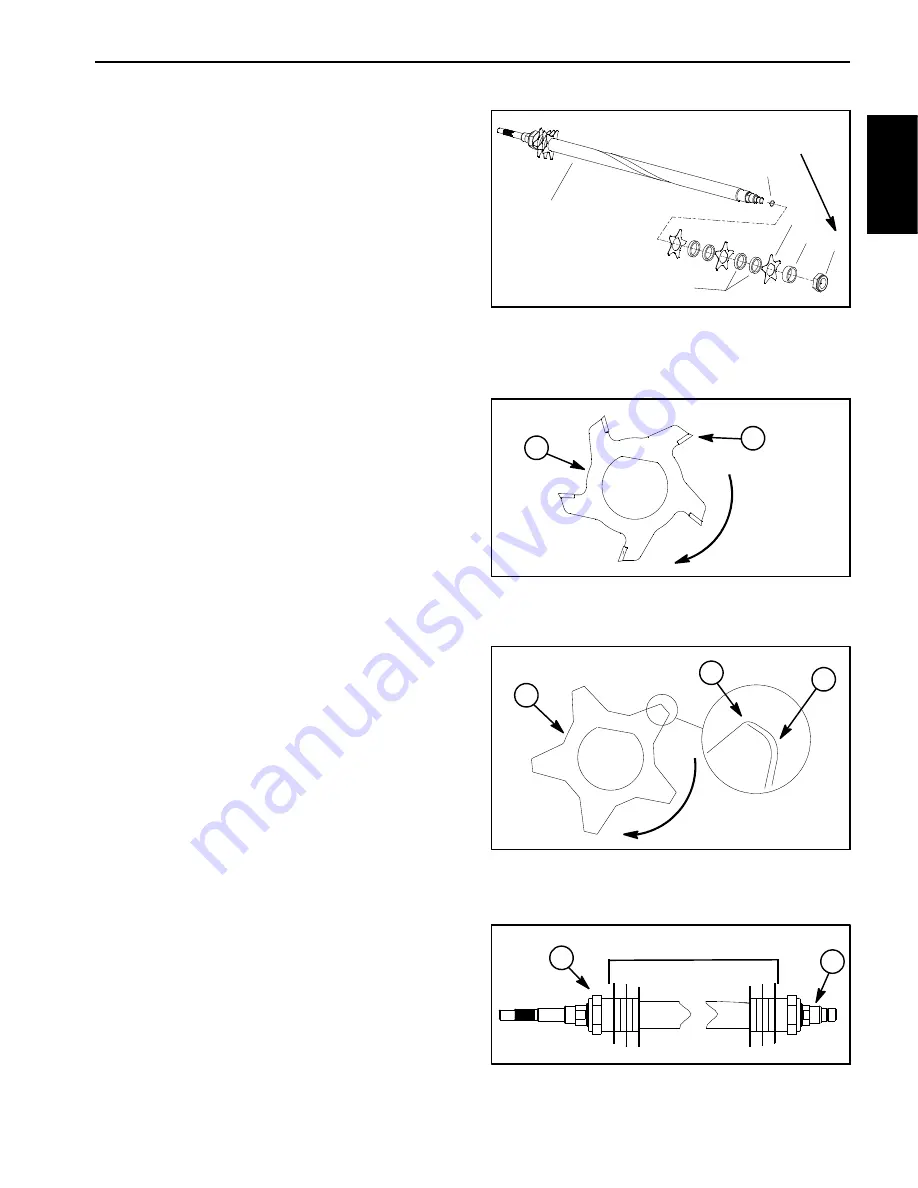

Grooming Reel Service

Inspect grooming reel blades frequently for damage and

wear. Straighten bent blades with a pliers. Replace

blades that are worn or damaged.

Carbide tipped grooming blades (Fig. 15) should be re-

placed if the carbide tip is worn, loose or missing. Also,

if the blade is eroded around the carbide insert, the

blade should be replaced.

Grooming blades without a carbide tip (Fig. 16) should

be replaced if worn or damaged. Blades without a car-

bide tip that are rounded to the midpoint of the blade tip

can be reversed on the grooming shaft to extend the life

of the blade.

Disassembly (Fig. 14)

1. Remove grooming reel from cutting unit (see Groom-

ing Reel Removal in this section).

2. Remove lock nut from either end of the shaft (Fig.

14).

3. Remove spacers and blades from groomer shaft as

necessary.

Assembly (Fig. 14)

1. Start by placing thick spacer against the lock nut

installed on one end of groomer shaft. Then, place first

blade against installed spacer (Fig. 14).

IMPORTANT: If groomer is equipped with blades

with carbide tips, make sure that blades are

installed with the tips in the same direction.

2. For 1/2 inch (1.3 cm) blade spacing, make sure there

are two (2) blade spacers between blades (Fig. 14).

3. When all blades have been installed, place second

thick spacer on shaft and then thread second lock nut

onto the shaft.

4. Position lock nuts to allow blades and spacers to be

centered on the shaft (Fig. 17). Torque lock nuts from

200 to 250 in--lb (23 to 28 N--m)

so spacers are

not

free

to rotate.

5. Install grooming reel back onto cutting unit (see

Grooming Reel Installation in this section).

1. Grooming reel shaft

2. Groomer blade

3. Blade spacer

4. Thick spacer (2 used)

5. Lock nut (2 used)

6. O--ring

Figure 14

3

2

4

1

5

6

200 to 250 in--lb

(23 to 28 N--m)

1. Grooming blade

2. Carbide tip

Figure 15

ROTATION

1

2

1. Grooming blade

2. Sharp edge

3. Dull (rounded) edge

Figure 16

ROTATION

3

2

1

1. Lock nut

2. Grooming shaft

Figure 17

CENTER BLADES ON SHAFT

2

1

Groomer

Summary of Contents for 04510 Greensmaster 3300 TriFlex

Page 2: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 4: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 6: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 24: ...Greensmaster 3300 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3400 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3300 3400 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 170: ...Greensmaster 3300 3400 Hydraulic System Page 5 118 This page is intentionally blank ...

Page 172: ...Greensmaster 3300 3400 Page 6 2 Electrical System This page is intentionally blank ...

Page 230: ...Greensmaster 3300 3400 Page 6 60 Electrical System This page is intentionally blank ...

Page 303: ...Greensmaster 3300 3400 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 318: ...Greensmaster 3300 3400 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 332: ...Page 10 16 This page is intentionally blank ...