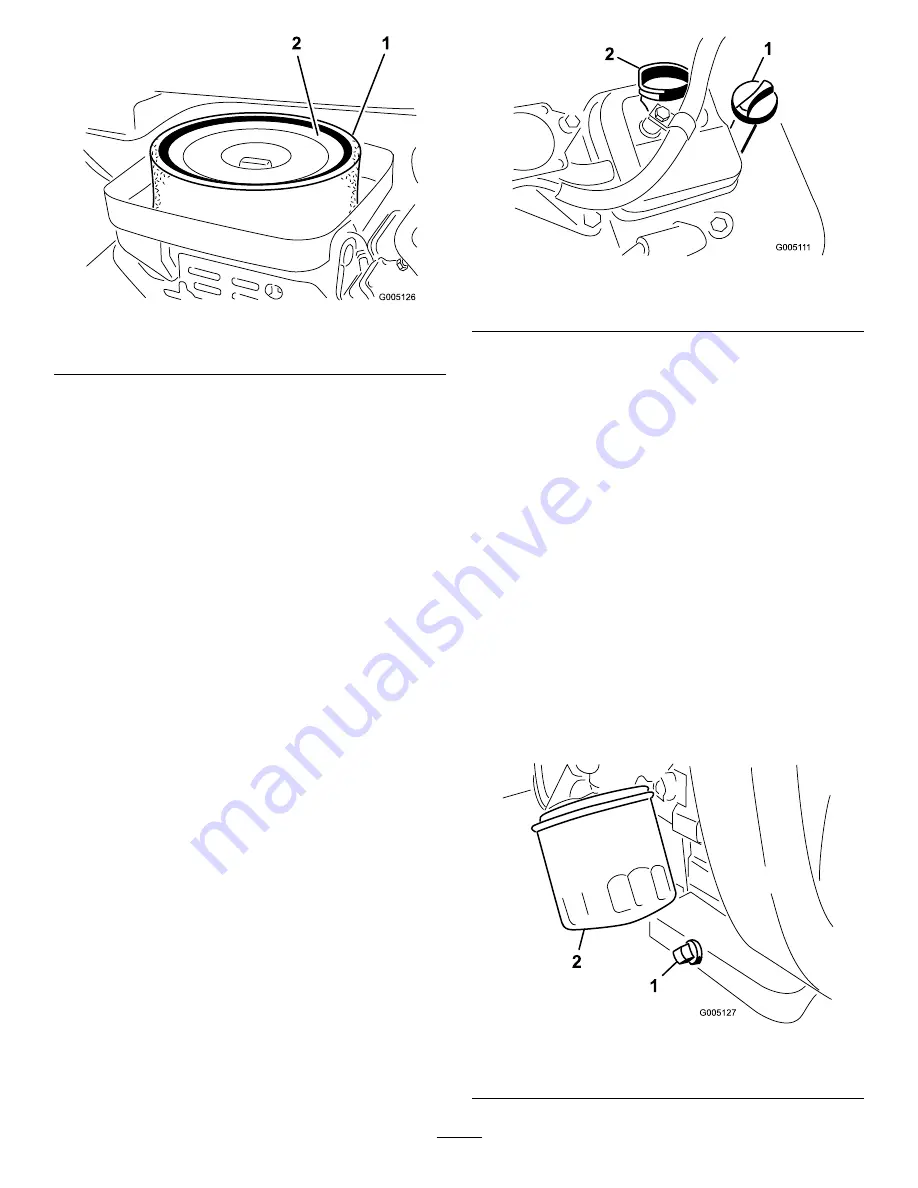

g005126

Figure 27

1.

Foam element

2.

Paper element

5.

Check the condition of the paper element. Clean

it by gently tapping it on a flat surface or replace

it if needed.

6.

Install the foam element, paper element, wing

nut, and air-cleaner cover.

Important:

Do not operate the engine

without the air-cleaner element because

extreme engine wear and damage will likely

result.

Servicing the Engine Oil

The engine is shipped with oil in the crankcase;

however, you must check the oil level before and after

starting the engine the first time.

Engine Oil Specification

API Oil Service Classification:

SJ or higher

Oil Viscosity:

SAE 30

Note:

Uses any high-quality detergent oil.

Checking the Engine Oil

1.

Position the machine on a level surface.

2.

Unscrew the dipstick, remove it, and wipe it with

a clean rag.

3.

Insert the dipstick into the dipstick tube and

thread it into the tube (

).

g005111

Figure 28

1.

Dipstick

2.

Filler cap

4.

Unscrew the dipstick, pull it out of the tube, and

check the oil level.

5.

If the oil level is low, remove the filler cap from

the valve cover and add oil into the engine

through the filler neck until the oil level is up to

the F

ULL

mark on the dipstick.

Add the oil slowly and check the level often

during this process.

Important:

Do not overfill the engine with

oil.

6.

Install the filler cap and dipstick.

Changing the Engine Oil and Filter

Service Interval:

After the first 25 hours

Every 100 hours

Engine oil quantity:

1.65 L (1-3/4 US qt) with filter

1.

Remove the drain plug (

) and let the

oil flow into a drain pan.

g005127

Figure 29

1.

Drain plug

2.

Oil filter

31