Adjusting the Clip Rate

The clip rate is determined by the following machine

settings:

•

Reel speed

: You can adjust the reel speed to a

high or low setting; refer to

.

•

Reel-drive-pulley position

: You can set the

reel-drive pulleys in 2 positions; refer to your

cutting unit

Operator’s Manual

.

To determine the reel speed and reel-drive-pulley

position for the appropriate clip, refer to the following

table:

Clip Rate

Cutting Unit

Reel

Speed

Belt

Position

8-blade

11-blade

14-blade

Low

Low

7.3 mm

(0.286 inch)

5.3 mm

(0.208 inch)

4.2 mm

(0.164 inch)

Low

High

8.7 mm

(0.241 inch)

4.4 mm

(0.175 inch)

3.5 mm

(0.137 inch)

High

Low

5.9 mm

(0.233 inch)

4.3 mm

(0.169 inch)

3.4 mm

(0.133 inch)

High

High

5.0 mm

(0.196 inch)

3.6 mm

(0.142 inch)

2.8 mm

(0.112 inch)

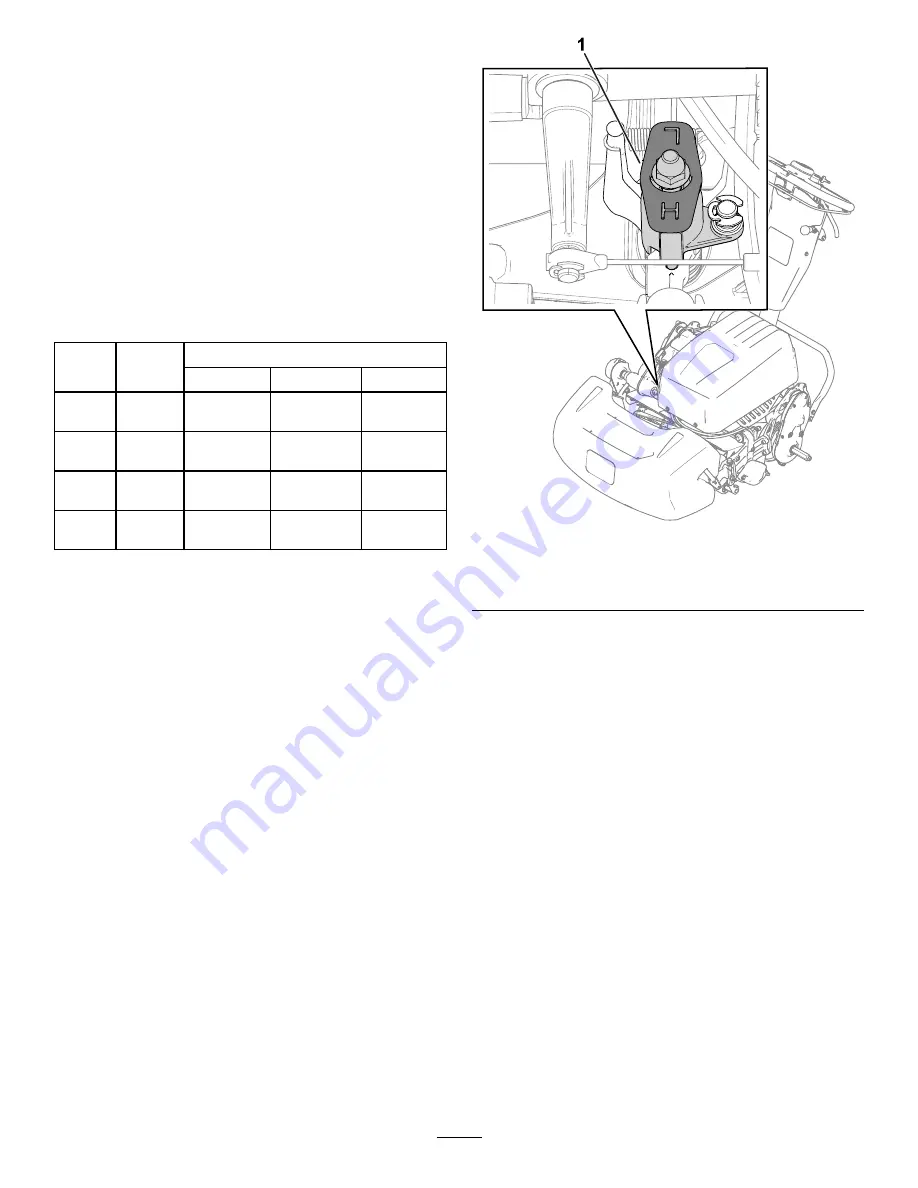

Adjusting the Reel Speed

Use the reel-speed-control knob (

) to adjust

the reel speed.

•

High reel speed

: Rotate the knob so that the “H”

on the knob is directed toward the front of the

machine.

•

Low reel speed

: Rotate the knob so that the “L”

on the knob is directed toward the front of the

machine.

g341648

Figure 15

1.

Reel-speed-control knob (shown in the high-reel-speed

position)

Adjusting the

Traction-Drum Position

The traction drum can be adjusted to 2 positions:

•

L

OW

position: Use this position for mowing at a

lower height of cut (e.g., mowing a golf-course

green).

•

H

IGH

position: Use this position for mowing at a

higher height of cut (e.g., mowing a golf-course

tee box).

1.

Move the kickstand to the C

UTTING

-U

NIT

S

ERVICE

position; refer to

.

2.

Remove the shoulder bolts (

) on each

side of the machine that secure the drum drive

housing to the chassis.

14