10

2.

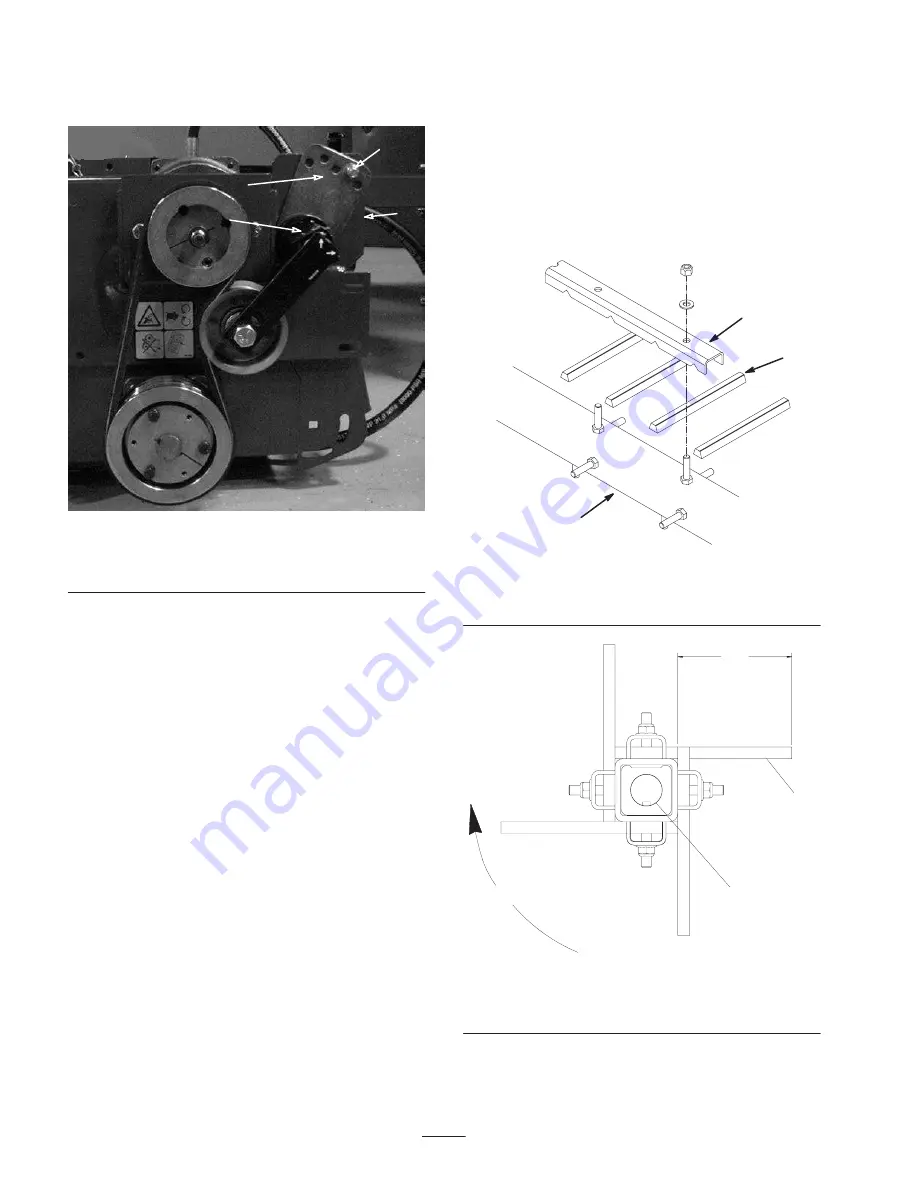

On back side of frame, loosen capscrew securing belt

tensioner to frame (Fig. 9).

1

2

3

4

Figure 9

1. Tensioner guide

2. Capscrew & nut

3. Capscrew (back of frame)

4. Tensioner

3.

Remove capscrew and nut securing tensioner guide to

drive mount (Fig. 9). Belt tension will be released when

capscrew is removed.

4.

Position a large wrench on tensioner. Rotate tensioner

clockwise until decal is aligned with 15

_

on tensioner

tube.

5.

Insert capscrew into aligned guide holes and secure

with nut. If holes are not exactly aligned, rotate guide to

the next higher hole until aligned.

6.

Tighten capscrew, on back side of frame to lock

tensioner.

7.

Install the motor shield with the fasteners previously

removed.

Replacing Finger Belts

1.

Loosen nuts and washers securing finger pinchers to

rotor (Fig. 10 & 11).

2.

Remove old belt fingers.

3.

Install new belt fingers. Belt fingers to extend from

finger pinchers approximately 4 inches (Fig. 10 & 11).

4.

Tighten nuts securing assembly.

1

3

2

Figure 10

1. Finger pincher

2. Rotor

3. Belt finger

1

2

3

4

Figure 11

1. 3.63 inches

2. Flat side of belt

3. Keyed shaft

4. Brush rotation

Summary of Contents for 07081

Page 11: ...11...