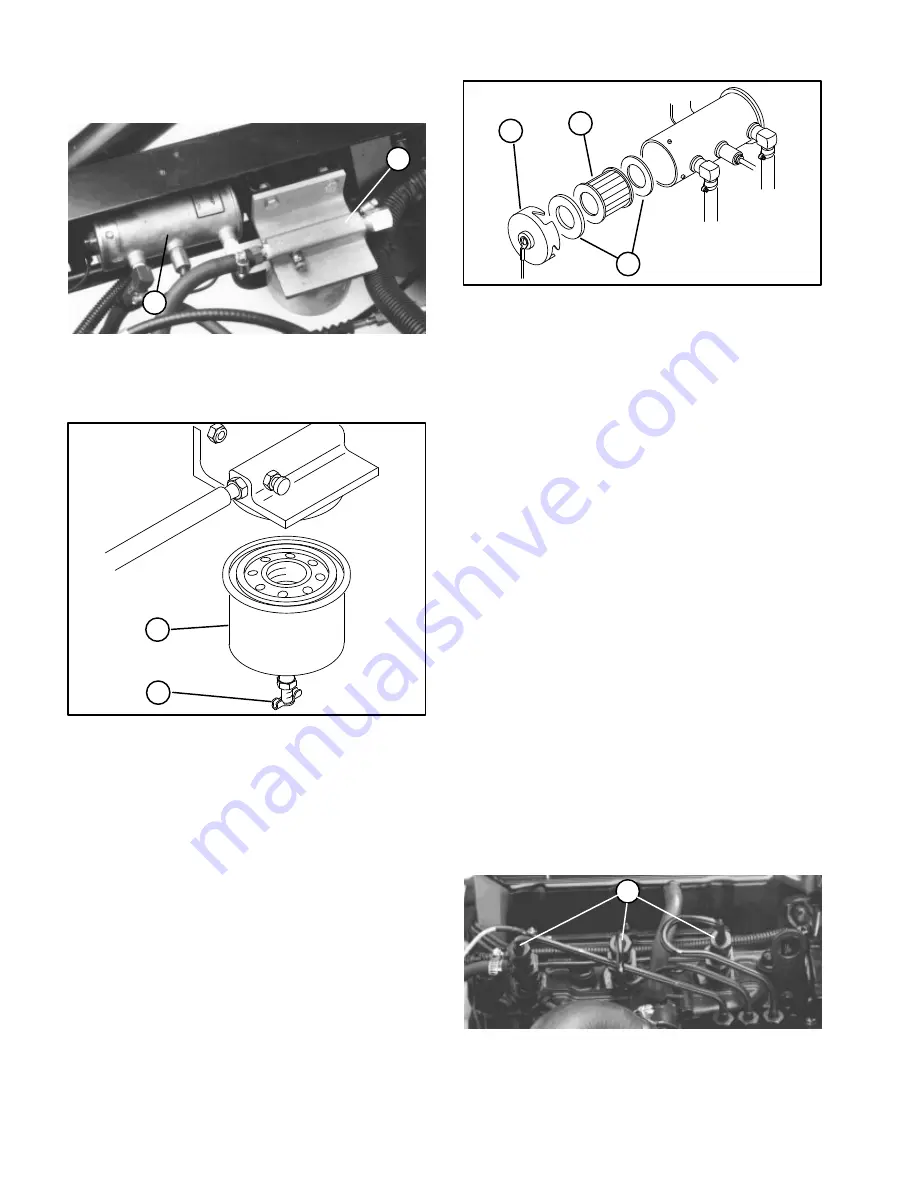

Fuel filter/water separator is mounted on inner side

of right frame rail (Fig. 35).

&%1.#

1#) $&)0#.3!0#. /#-!.!0,.

1#) -1*-

Clean area around filter canister mounting surface.

&%1.#

.!&+ -)1%

&)0#. "!+&/0#.

Remove filter canister and clean mounting surface.

Lubricate gasket on filter canister with clean

engine oil.

Install filter canister by hand until gasket contacts

mounting surface, then rotate an additional 1/2 turn.

1#) 1*- &)0#.

Remove and replace the filter after every 400 hours

operation.

Raise bed (if so equipped) and place a safety

support under it to hold up bed.

Fuel pump is mounted on inner side of right frame

rail (Fig. 35).

Thoroughly clean outside of assembly.

Place a drain pan under fuel pump and remove

cover from fuel pump (Fig. 37). Take care not to

damage wire while removing cover.

&%1.#

1#) -1*- ",2#.

&)0#.

!/(#0

Pull filter out of pump body (Fig. 37).

If filter is to be cleaned, wash thoroughly in

cleaning solvent and blow compressed air from inside

toward outside of element. Hold air nozzle at least one

inch (25 mm) from filter and move up and down while

rotating filter. Do not exceed 100 psi (689 kPa) to avoid

filter damage.

,0#

Replace the filter if there is any visible dirt which

cannot be washed out.

Inspect the two rubber gaskets; replace them if

damaged.

Clean cover of any residue (Fig. 37), insert filter into

body and install cover.

Bleed the fuel system; refer to Bleeding Fuel

System.

&%

,0#

This procedure should be used only if fuel

system has been purged of air through normal priming

procedures and engine still will not start; refer to

Bleeding Fuel System.

Raise bed (if so equipped) and place a safety

support under it to hold up bed.

Loosen the pipe connection to the No. 1 nozzle

and holder assembly (Fig. 38).

&%1.#

1#) &+'#"0,./

Slowly depress accelerator pedal to full FAST

position.