!

Turn key in key switch to START position and watch

fuel flow around connector. Turn key to OFF position

when solid flow is observed.

Tighten pipe connector securely.

Repeat steps 1Ć4 on No. 2 and 3 nozzles.

#

$ !

-+

Remove debris from engine area and radiator daily,

clean more frequently in dirty conditions.

Remove radiator cover.

Turn engine off. Clean engine area thoroughly of all

debris.

Remove screen cover from front of radiator.

Open radiator screen clean out door at lower left

side of radiator and remove all debris from bottom of

radiator inlet area.

Clean radiator thoroughly with water or

compressed air.

-+74)

%(-%624 5'4))1 '28)4

/)%1 276 (224

!

-+

Park machine on a level surface.

* )1+-1) ,%5 &))1 4711-1+ 34)5574-:)(

,26 '22/%16 '%1 )5'%3) -* 4%(-%624 '%3 -5

4)028)( %1( '%75) &7415 //29 )1+-1)

62 '22/ %6 /)%56 0-176)5 24 716-/ 6,)

4%(-%624 '%3 -5 '22/ )127+, 62 627',

9-6,276 &741-1+ ,%1(

"!

Raise bed (if so equipped) and place a safety

support under it to hold up bed.

Remove radiator and reserve tank caps.

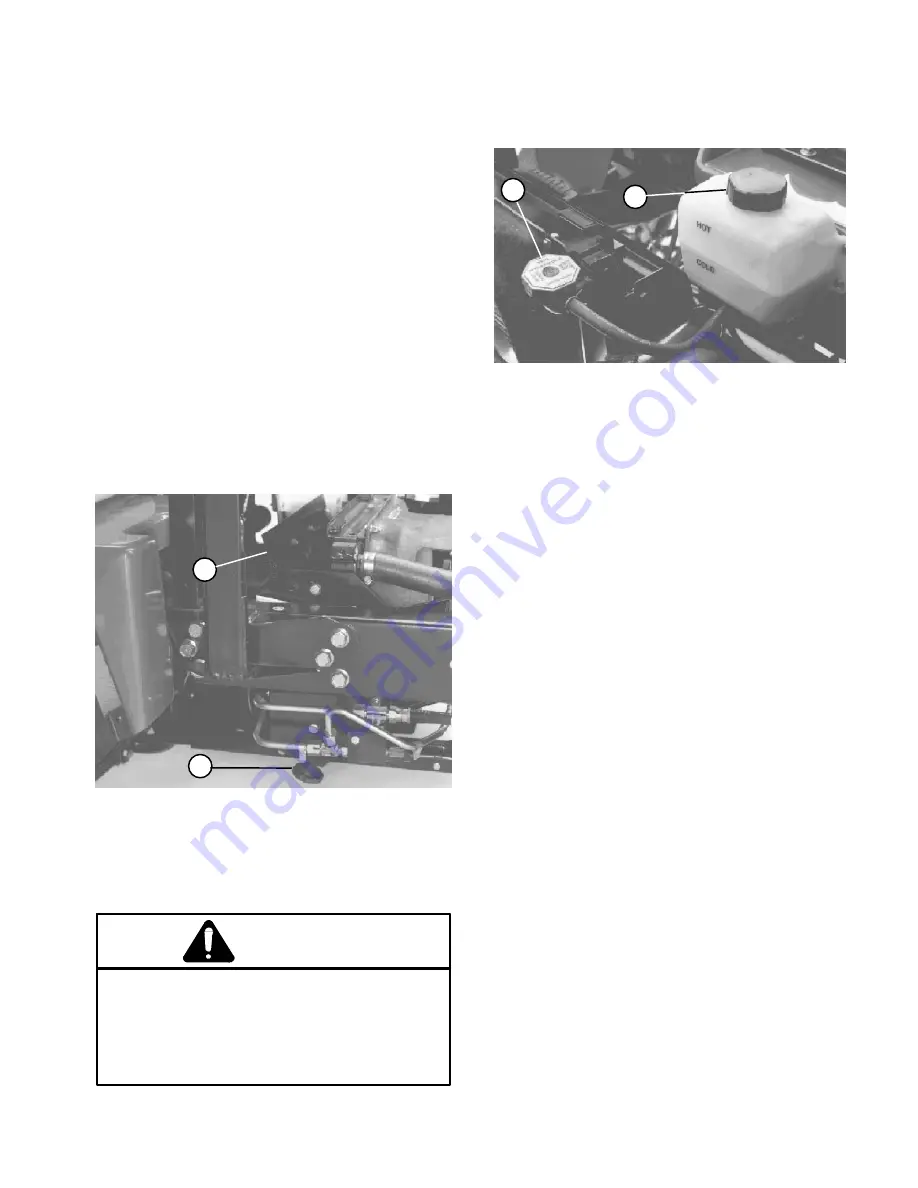

-+74)

%(-%624 '%3

)5)48) 6%1. '%3

Open coolant drain cock at bottom of radiator and

allow coolant to flow into drain pan. When coolant

stops, close drain cock.

Remove coolant drain plug from engine and allow

coolant to flow into drain pan. When coolant stops,

install drain plug.

Slowly fill radiator with a 50/50 mixture of water and

permanent ethylene glycol anti-freeze. Install radiator

cap.

Slowly fill reserve tank until level reaches COLD

line.

! #

. Install reserve tank cap.

Start engine and operate until warm. Recheck level

and replenish, if required.

" ! !

-+

Check condition and tension of all belts after first day of

operation and every 200 operating hours thereafter.

Raise bed (if so equipped) and place a safety support

to hold up bed.

/6)41%624 &)/6 -+

Check tension by depressing belt at mid span of

crankshaft and alternator pulleys with 22 lbs. of force. A

new belt should deflect .3-.5 in. A used belt should

deflect .4-.55 in. If deflection is incorrect, proceed to

next step. If correct, continue operation.

To adjust belt tension:

Loosen alternator mounting bolts.

Using a bar, rotate alternator until proper belt

tension is attained, then tighten mounting bolts.