Checking the Cooling System

Service Interval:

Before each use or daily

Cooling system capacity:

4 qt (3.7 l)

The cooling system is filled with a 50/50 solution of

water and permanent ethylene glycol antifreeze.

1. Park the machine on a level surface.

CAUTION

If the engine has been running, the pressurized,

hot coolant can escape and cause burns.

•

Do not open the radiator cap when the

engine is running.

•

Allow the engine to cool at least 15 minutes

or until the radiator cap is cool enough to

touch without burning your hand.

•

Use a rag when opening the radiator cap,

and open the cap slowly to allow steam to

escape.

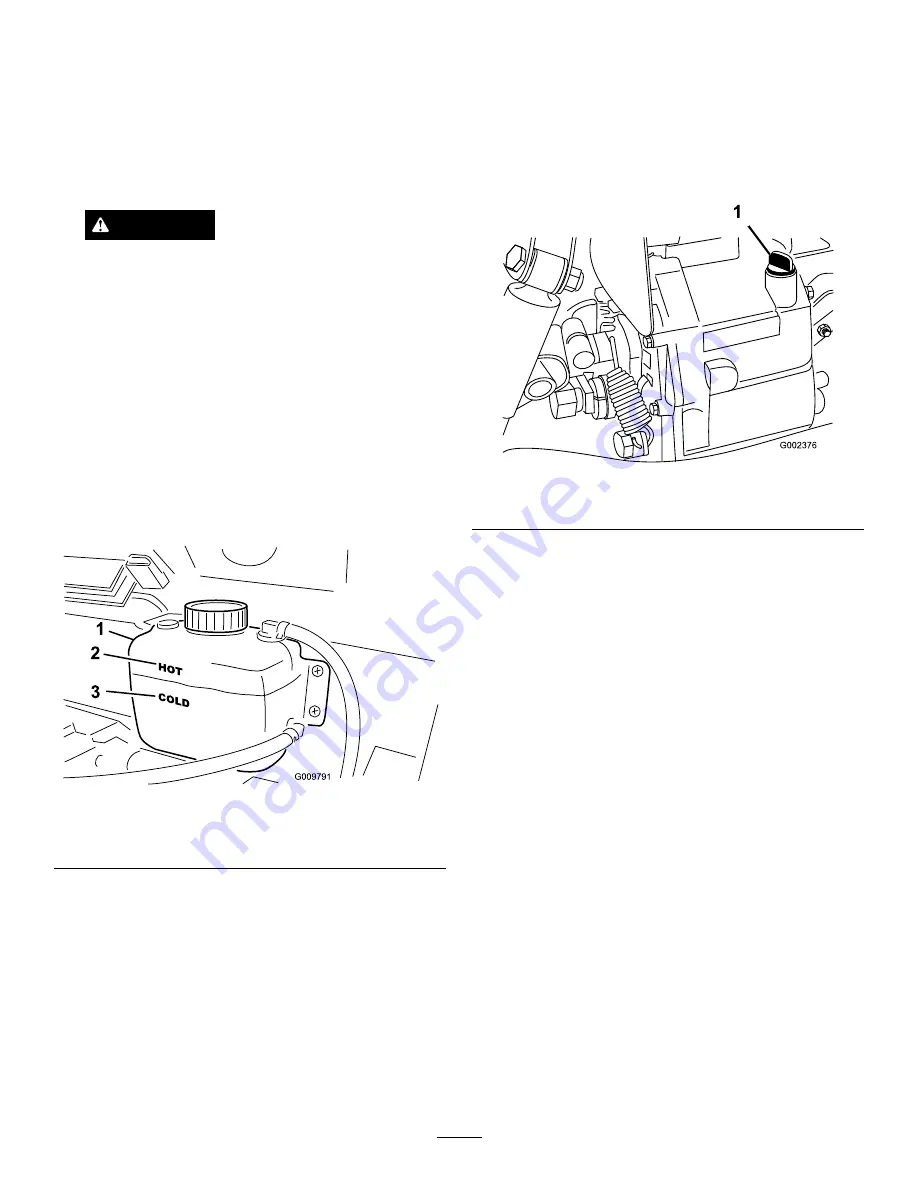

2. Check the coolant level on the side of the reserve

tank (Figure 18). The coolant should be up to the

Cold line, when engine is cold.

Figure 18

1.

Reserve tank

3.

Cold line

2.

Hot line

3. If coolant is low, remove the reserve tank cap

and add a 50/50 mixture of water and permanent

ethylene glycol antifreeze.

Do not overfill.

4. Install the reserve tank cap.

Checking the

Transaxle/Hydraulic Fluid

Level

Service Interval:

Before each use or daily

The transaxle reservoir is filled with Dexron III ATF.

Check the level before the engine is first started and

every 8 hours or daily, thereafter. Capacity of system is .

Transaxle reservoir capacity:

7.5 qt (7 l).

1. Position the vehicle on a level surface.

2. Clean the area around the dipstick (Figure 19).

Figure 19

1.

Dipstick

3. Unscrew the dipstick from the top of the transaxle

and wipe it with a clean rag.

4. Screw the dipstick into the transaxle and ensure that

it is fully seated.

5. Unscrew the dipstick and check the fluid level.

The fluid should be up to top of the flat portion

of the dipstick.

6. If the level is low, add enough fluid to achieve the

proper level.

Checking the High Flow

Hydraulic Fluid (TC models

only)

Service Interval:

Before each use or daily

The high flow hydraulics reservoir is filled with

approximately 4 US gallons (15 l) of high quality

hydraulic fluid.

Check the level of hydraulic

fluid before the engine is first started and daily

thereafter.

1. Clean the area around the filler neck and the cap

of the hydraulic tank (Figure 20). Remove the cap

from the filler neck.

23

Summary of Contents for 07367TC

Page 41: ...Figure 44 41...

Page 60: ...Schematics Hydraulic Schematic Rev B High Flow Hydraulics Schematic TC models only Rev A 60...

Page 61: ...Electrical Schematic Rev B 61...

Page 62: ...Notes 62...

Page 63: ...Notes 63...