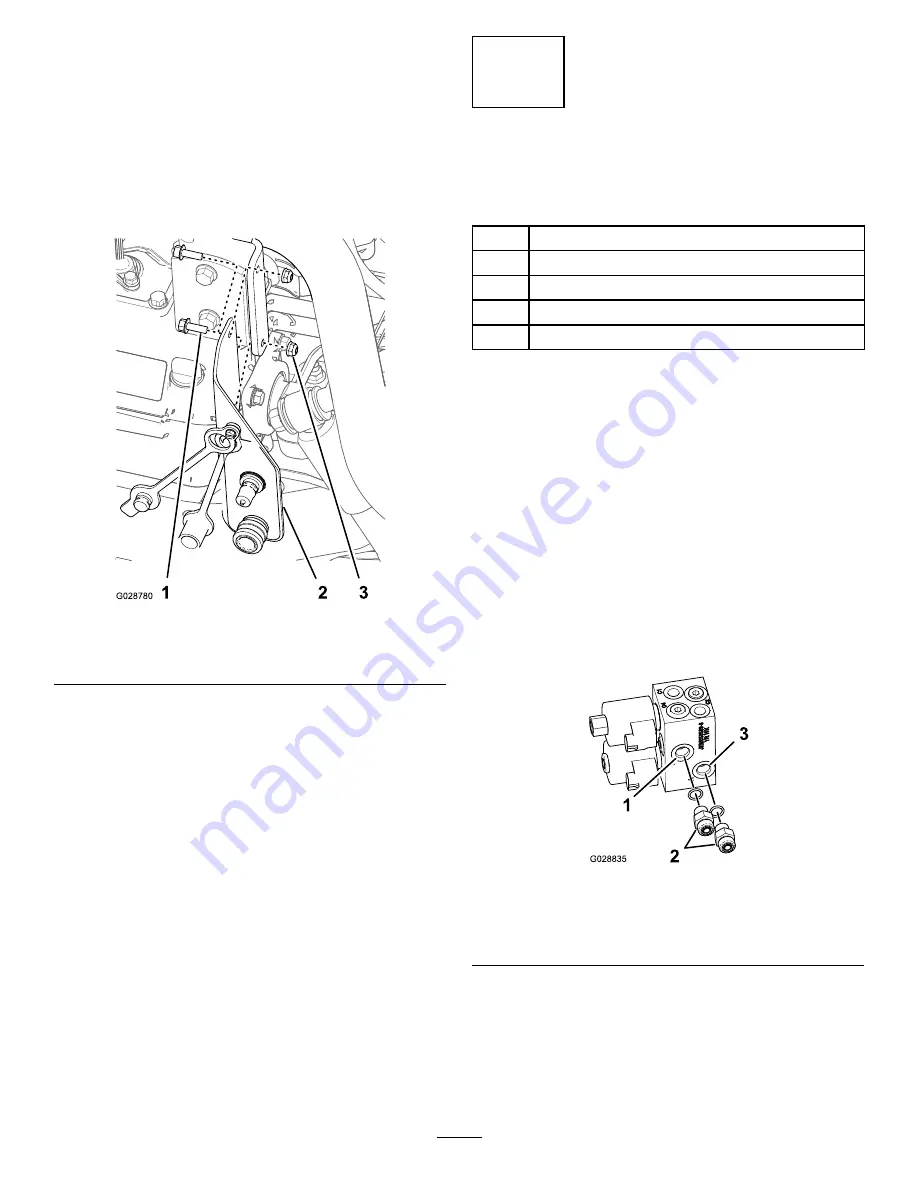

Removing the Quick Disconnect

Bracket

1.

Remove the 2 flanged head bolts and 2 flanged locknuts

that secure the quick disconnect bracket to the flange

of the transmission support of the machine (

)

Note:

Retain the flanged head bolt and flanged

locknut for installation of the manifold bracket in

Installing the Manifold Bracket and Hydraulic Control

Manifold (page 12)

.

Figure 17

1.

Flanged head bolt

3.

Flanged head nut

2.

Quick disconnect bracket

2.

Remove the bracket from the machine (

).

3.

Remove the straight fittings and the quick disconnect

coupling from the quick disconnect bracket.

Note:

Retain the male and female quick disconnect

couplings and straight fittings; discard the bracket.

7

Preparing the Hydraulic

Control Manifold

Parts needed for this procedure:

1

Hydraulic control manifold

1

Straight hydraulic fitting (11/16 x 9/16 x 3/8 inch)

1

45° hydraulic fitting

3

90° hydraulic fitting

2

Straight hydraulic fittings (9/16 x 9/16 x 3/8 inch)

Preparing the Hydraulic Control

Manifold (non-HDX-Auto Workman

models)

Note:

Ensure that the O-rings are installed on the fittings

and lubricated with hydraulic fluid from the machine before

installing the fittings into the manifold.

1.

Install the A and B port fittings into the manifold as

follows:

•

For 2000 and 3000 series Workman

Install the 2 straight hydraulic fitting that you

removed in step

of

Disconnect Bracket (page 10)

into ports A and B

of the maniflod (

Figure 18

1.

Port B (hydraulic control

manifold)

3.

Port A (hydraulic control

manifold)

2.

Straight hydraulic fitting

•

For HD, HDX, and HDX-D Workman

A.

Install 1 of the straight hydraulic fittings that

you removed in step

of

Disconnect Bracket (page 10)

into port B of

the hydraulic control manifold (

).

10