23

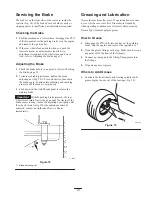

Servicing the Brake

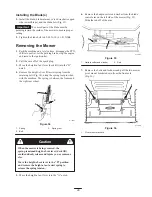

The brake is on the right side of the rear axle, inside the

rear tire (Fig. 18). If the brake does not hold securely or

stopping power is insufficient, an adjustment is required.

Checking the Brake

1. Park the machine on a level surface, disengage the PTO,

shift into neutral, set the parking brake, stop the engine,

and remove the ignition key.

2. If the rear wheels lock and skid when you push the

tractor forward, no adjustment is required. An

adjustment is required if the wheels turn and do not

lock; refer to Adjusting the Brake, page 23.

Adjusting the Brake

1. Check the brake before you adjust it; refer to Checking

the Brake, page 23.

2. To increase braking resistance, tighten the brake

adjusting nut (Fig. 18) 1/8 turn clockwise; then check

the brake again. Continue this adjusting and checking

process until the brake is set properly.

3. Push down on the clutch/brake pedal to release the

parking brake.

Important

With the parking brake released, the rear

wheels must rotate freely when you push the tractor. If the

brake seems to drag, loosen the adjusting nut slightly until

the wheels rotate freely. If both conditions cannot be

achieved, contact an Authorized Service Dealer

immediately.

m–1895

1

Figure 18

1.

Brake adjusting nut

Greasing and Lubrication

Grease the machine after every 25 operating hours or once

a year, whichever occurs first. Grease more frequently

when operating conditions are extremely dusty or sandy.

Grease Type: General-purpose grease

How to Grease

1. Disengage the PTO, shift into neutral, set the parking

brake, stop the engine, and remove the ignition key.

2. Clean the grease fittings with a rag. Make sure to scrape

any paint off of the front of the fitting(s).

3. Connect a grease gun to the fitting. Pump grease into

the fittings.

4. Wipe up any excess grease.

Where to Add Grease

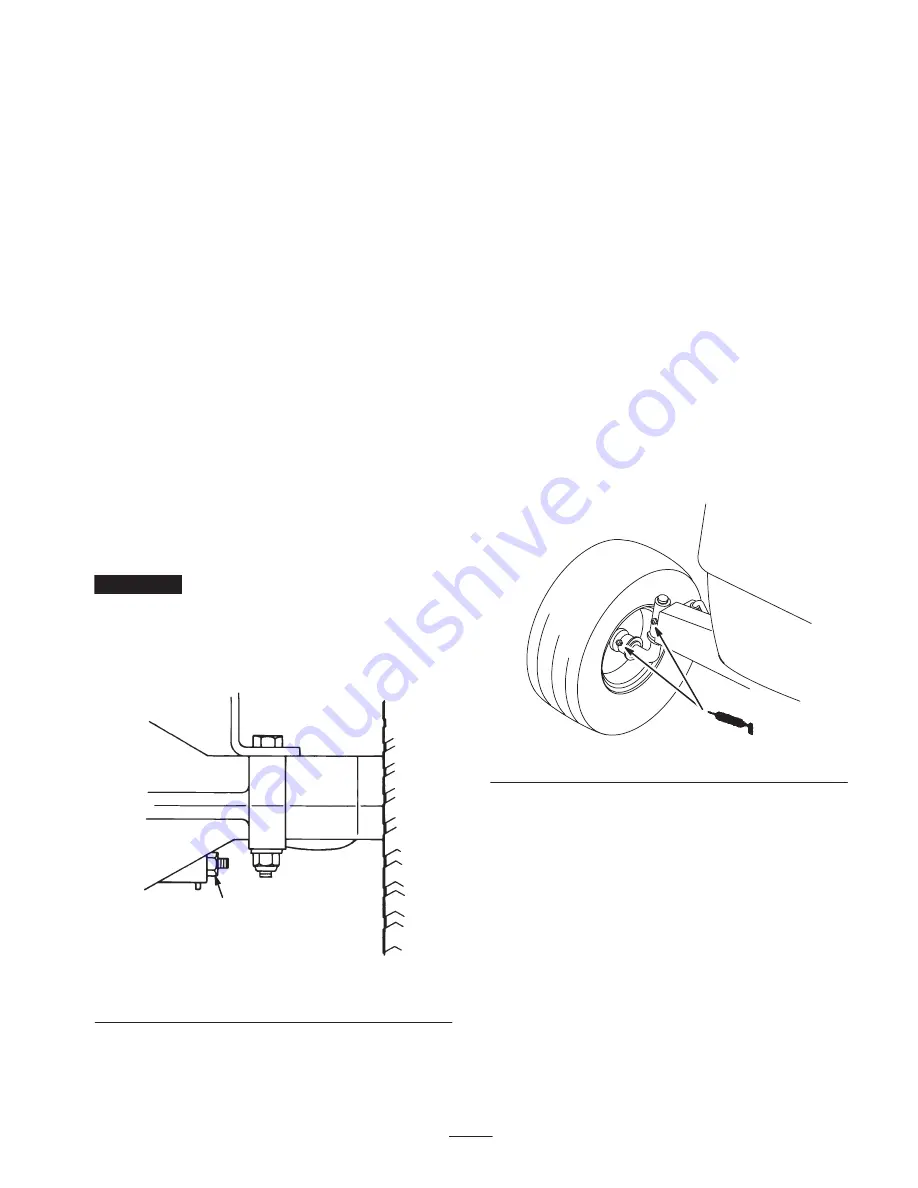

1. Lubricate the front wheels and steering spindles until

grease begins to ooze out of the bearings (Fig. 19).

m–2346

Figure 19