33

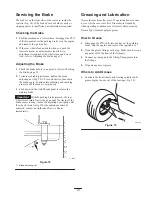

Front-to-Rear Blade Slope

Check the front-to-rear blade slope any time you install the

mower. Before you check the slope, set the air pressure in

the front and rear tires to the recommended inflation; refer

to Checking the Tire Pressure, page 25. If the front of the

mower is more than 5/8 in. (16 mm) lower than the rear of

the mower, adjust the blade slope using the following

instructions:

1. Park the machine on a level surface, disengage the PTO,

shift into neutral, set the parking brake, stop the engine,

and remove the ignition key.

2. Pull the wire off of the spark plug.

3. Check and adjust side-to-side blade level if you have

not checked the setting; refer to Side-to-Side Mower

Leveling, page 32.

4. Move the height-of-cut lever into the “C” notch.

5. Check the front-to-rear blade slope by measuring

between the bottom of the mower (front center and rear

center) and the flat surface (Fig. 46). If the front of the

mower is more than 5/8 in. (16 mm) lower than the rear

of the mower, an adjustment is required; refer to

steps 6–10.

m–1801

2

1

1

2

Figure 46

1.

Measure front center

2.

Measure rear center

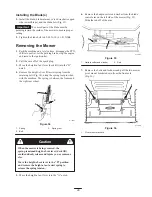

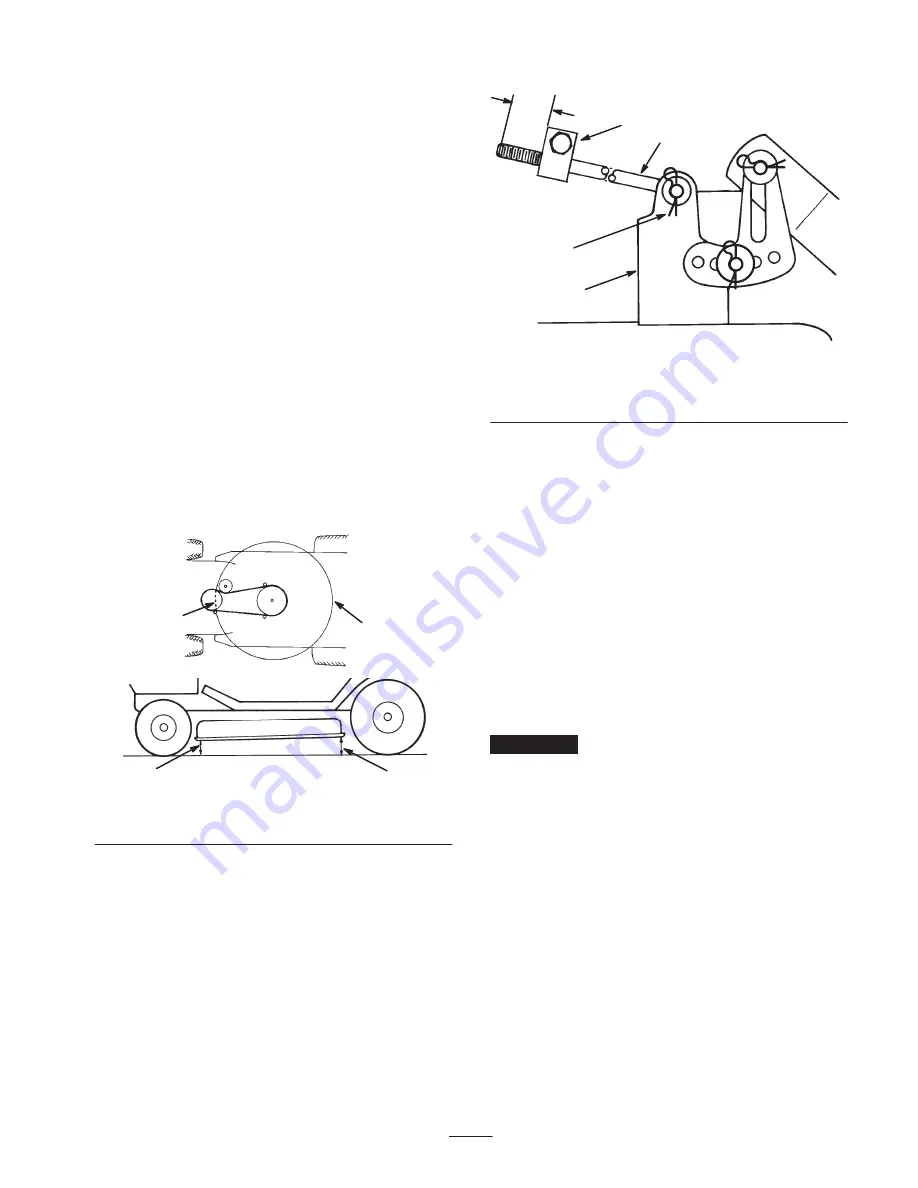

6. Measure the length of the rod extending out of the front

of the adjusting block on the sides of the chassis

(Fig. 47). If the rod length is not 5/8 in. (16 mm),

remove the hairpin cotter and washer from the end of

the rod (Fig. 47), and turn the rod until the 5/8 in.

(16 mm) dimension is obtained. Then install the end of

the rod into the hole in the mower mount and secure it

in place with the washer and hairpin cotter. Repeat this

procedure on the opposite side of the mower.

m–1805

5/8 in.

(16 mm)

1

2

3

4

Figure 47

1.

Adjusting block

2.

Long rod

3.

Hairpin cotter and washer

4.

Mower mount

7. Check the front-to-rear slope again. If the front of the

mower is more than 5/8 in. (16 mm) lower than the rear

of the mower, proceed to step 8 for the adjusting

instructions. Otherwise, recheck the side-to-side level to

ensure it did not change.

8. Adjust the front-to-rear slope by rotating the special

slope adjusting nuts on both sides of the mower pivot

mount (Fig. 48).

9. Using a 1 in. wrench or socket, slowly rotate the left

side slope adjusting nut down to raise the front of the

mower and up to lower it (Fig. 48). Rotate the slope

adjusting nut until the front of the mower is 1/4 to

5/8 in. (6 to 16 mm) lower than the rear of the mower.

10. Slowly rotate the right side slope adjusting nut until

both adjusting nuts are in the same position.

Important

If the slope adjustment does not stay in

position after you adjust it, tighten the center bolt and

locknut and repeat step 9.