Cooling System

Maintenance

Cleaning the Engine Cooling

Areas

Clean the rotating screen, cooling fins, and external

surfaces of the engine every 100 operating hours or

more often under extremely dusty and dirty conditions.

Important:

Operating the engine with a blocked

rotating screen, dirty or plugged cooling fins, or

cooling shrouds removed will cause engine damage

due to overheating.

Important:

Never clean the engine with

pressurized water because water could contaminate

the fuel system.

Brake Maintenance

Inspecting the Brakes

Brakes are a critical safety component of the vehicle.

As with all safety components, they should be closely

inspected at regular intervals to ensure optimum

performance and safety. The following inspections

should be done every 100 hours:

•

Inspect the brake shoes for wear or damage. If the

lining (brake pad) thickness is less than 1/16 inch

(1.6 mm), the brake shoes should be replaced.

•

Inspect the backing plate and other components

for signs of excessive wear or deformation. If any

deformation is found, the appropriate components

must be replaced.

•

Check the brake fluid level; refer to Checking the

Brake Fluid Level.

Checking the Brake Fluid

Level

The brake fluid reservoir is filled and shipped from the

factory with DOT 3 brake fluid. Check the level before

the engine is first started and every 8 hours or daily,

thereafter.

1. Park the machine on a level surface, set the parking

brake, turn the ignition off, and remove the key.

2. Look at the side of the reservoir. The level should

be above the Minimum line (Figure 50). If the fluid

level is low, clean the area around the cap, remove

the cap, and fill the reservoir to above the Minimum

line. Do not overfill.

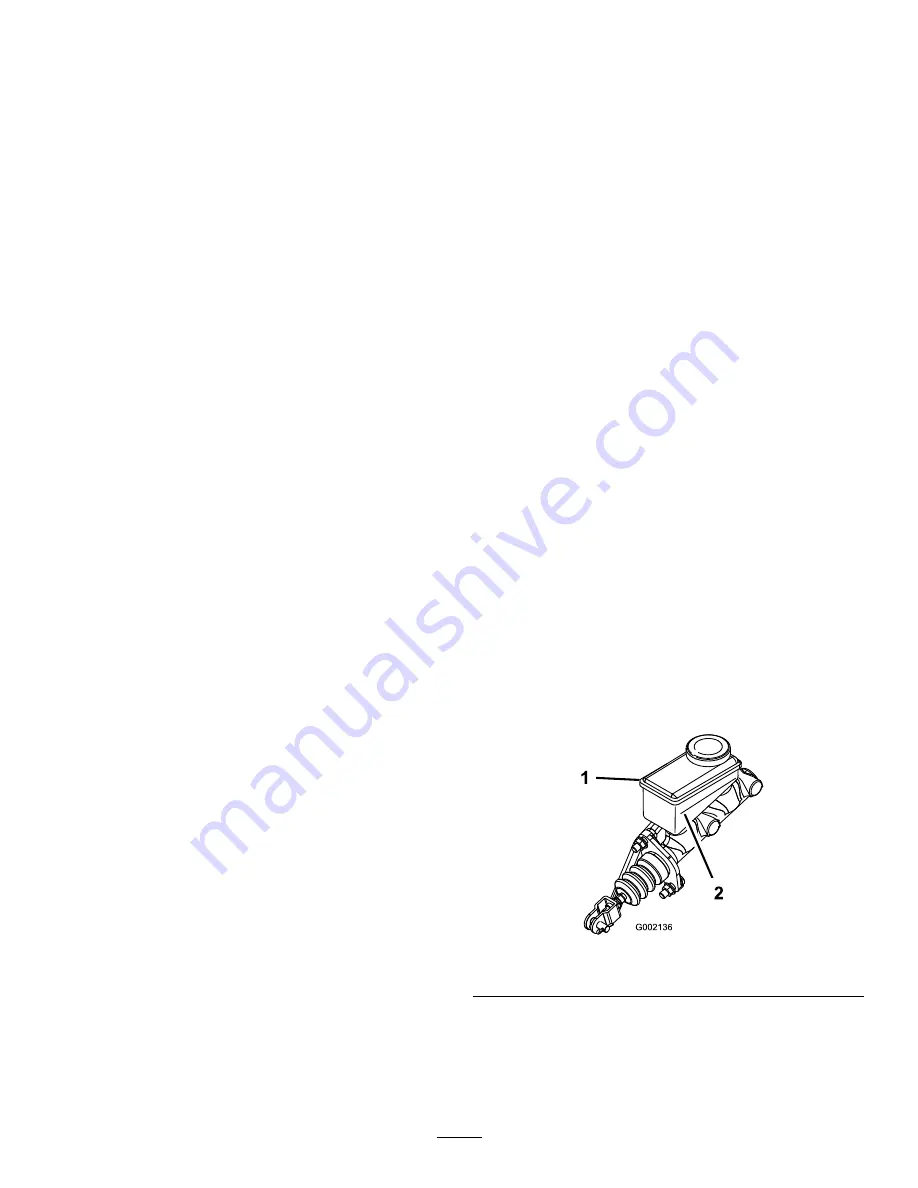

Figure 50

1.

Brake fluid reservoir

2.

Minimum line

Adjusting the Parking Brake

Check the parking brake adjustment every 200 hours.

1. Pry the rubber cover off of the parking brake.

37