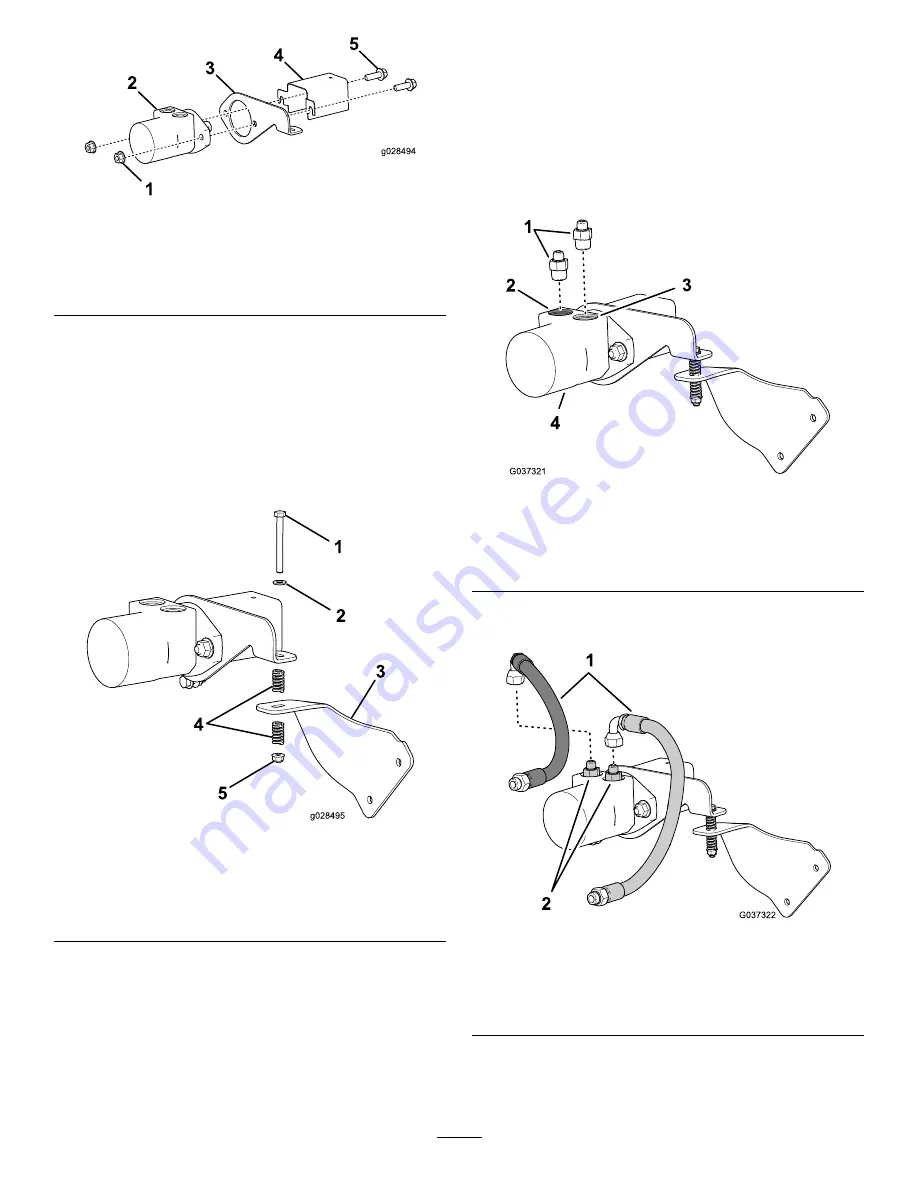

Figure 2

1.

Flange nut—1/2 inch (2)

4.

Shaft guard

2.

Hydraulic motor

5.

Flange-head bolt—1/2 x

1-1/2 inches (2)

3.

Motor bracket

3.

Attach the anti-rotation bracket to the motor bracket

with a flange head bolt (5/16 x 3 inches), a flat washer,

2 compression springs, and a flange locknut (5/16

inch) as shown in

Note:

Torque the nut until 2 threads of the bolt

extend beyond the end of the nut.

Note:

Ensure that the bottom of the locknut is flush

with the end of the spring.

Figure 3

1.

Flange-head bolt (5/16 x 3

inches)

4.

Compression springs

2.

Flat washer

5.

Flange locknut (5/16 inch)

3.

Anti-rotation bracket

Assembling the Fittings and Hoses to

the Hydraulic Motor

1.

Install a straight hydraulic fitting (5/8 inch) onto the

port-A of the hydraulic motor and a straight hydraulic

fitting (5/8 inch) onto the port-B of the hydraulic

motor (

Note:

Torque the fittings to 79 to 98 N∙m (58 to 72

ft-lb).

Figure 4

1.

Straight-hydraulic

fittings—7/8 inch (2)

3.

Port-B (hydraulic-motor

case)

2.

Port-A (hydraulic-motor

case)

4.

Hydraulic motor

2.

Mark the straight end of 1 hydraulic hose (1/2 x 17

inch) with a piece of tape (

).

Figure 5

1.

Hydraulic hose (1/2 x 17

inch)

3.

Straight-hydraulic fitting

(port-A)

2.

Tape marker (hydraulic

hose—port-A)

4.

Straight-hydraulic fitting

(port-B)

3.

Assemble the 90-degree fitting of the marked hydraulic

hose onto the straight fitting in port-A of the hydraulic

motor (

3