21

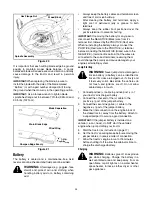

Steering Adjustment

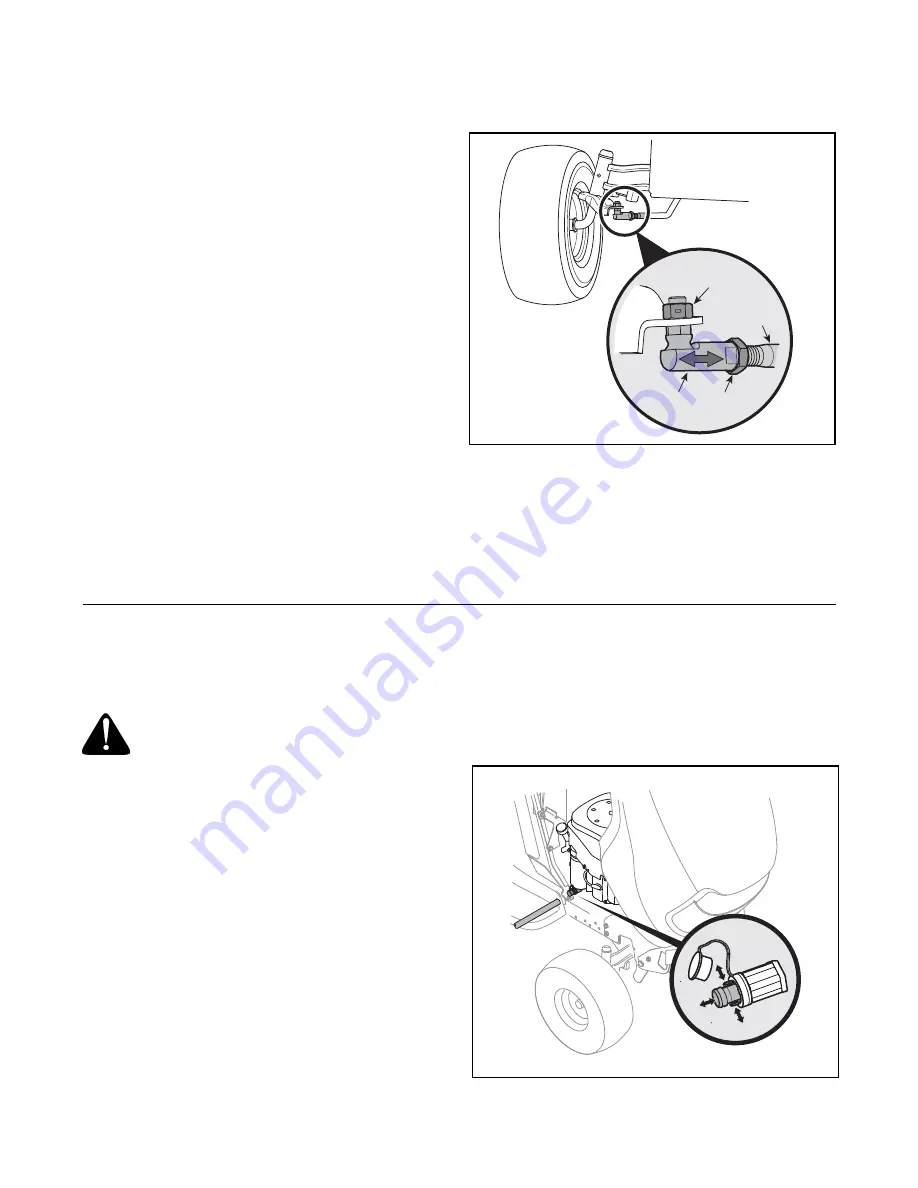

If the tractor turns tighter in one direction than the other,

or if the ball joints are being replaced due to damage or

wear, the steering drag links may need to be adjusted.

Adjust the drag links so that equal lengths are threaded

into the ball joint on the left side and the ball joint on the

right side:

1.

Loosen the jam nut found on the drag link at the

rear of the ball joint. See Figure 16 .

2.

Remove the hex nut on the top of ball joint.

SeeFigure 16 .

3.

Thread the ball joint toward the jam nut to shorten

the drag link. Thread the ball joint away from the

jam nut to lengthen the drag link.

4.

Replace hex nut and retighten the jam nut after

proper adjustment is achieved.

NOTE:

Threading the ball joints too far onto the drag

links will cause the front tires to "toe-in" too far. Proper

toe-in is between 1/16" and 5/16".

Front tire toe-in can be measured as follows:

1.

Place the steering wheel in position for straight

ahead travel.

2.

In front of the axle, measure the distance

horizontally from the inside of the left rim to the

inside of the right rim. Note the distance.

3.

Behind the axle, measure the distance horizontally

from the inside of the left rim to the inside of the

right rim. Note the distance.

Figure 16

4.

The measurement taken in front of the axle should

be between 1/16" and 5/16" less than the

measurement taken behind the axle.

5.

Adjust if necessary.

SECTION 8: MAINTAINING YOUR LAWN TRACTOR

NOTE:

Refer to

Maintenance Chart

on page 26 for a

reference of recommended maintenance intervals.

WARNING:

Before performing any

maintenance or repairs, disengage PTO, set

parking brake, stop engine and remove key to

prevent unintended starting.

Engine

Refer to the separate engine manual for engine

maintenance instructions.

Check

engine oil level

before each use as instructed in

the separate engine manual packed with your unit.

Read and follow instructions carefully.

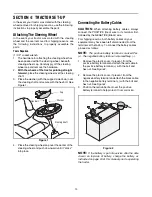

Changing Engine Oil

NOTE:

Depending on the engine model found on your

tractor, it may be necessary to remove the tractor’s side

panel in order to replace the oil filter (if so equipped).

1.

Pop open the protective cap on the end of the oil

drain valve to expose the drain port. See Figure 17 .

2.

Remove the oil fill cap/ dipstick from the oil fill tube.

3.

Push the oil drain hose (packed with this manual)

onto the oil drain port. Route the opposite end of

the hose into an appropriate oil collection container

with a capacity great enough to collect the used oil.

4.

Pinch the tabs on the oil drain valve, then pull

outward to begin draining oil. See Figure 17 .

Figure 17

Drag Link

Hex Nut

Jam

Nut

Ball

Joint

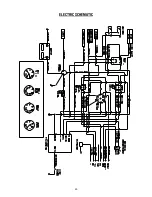

Summary of Contents for 14AQ81RP848

Page 30: ...30 ELECTRIC SCHEMATIC ...

Page 34: ...34 notes ...

Page 35: ...35 notes ...

Page 36: ...33 notes ...