23

1

2

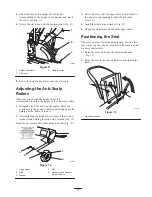

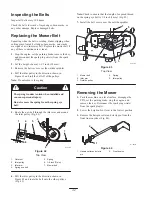

Figure 20

1.

Air cleaner cover

2.

Air cleaner cover handle

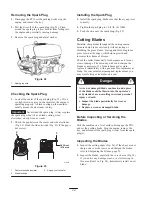

3. Carefully slide the paper element and foam element

from the blower housing (Fig. 21).

2

1

3

5 4

Figure 21

1.

Paper element

2.

Foam element

3.

Air cleaner cover

4.

Tab

5.

Slot

Cleaning the Foam and Paper Elements

Foam Element:

1. Wash the foam element in liquid soap and warm water.

When the element is clean, rinse it thoroughly.

2. Dry the element by squeezing it in a clean cloth. Do

not oil the element.

Important

Replace the foam element if it is torn or

worn.

Paper Element:

1. Lightly tap the element on a flat surface to remove

dust and dirt.

2. Carefully clean the rubber seal on the paper element to

prevent debris from entering the engine.

3. Inspect the element for tears, an oily film, and damage

to the rubber seal.

Important

Never clean the paper element with

pressurized air or liquids, such as solvent, gas, or

kerosene. Replace the paper element if it is damaged or

cannot be cleaned thoroughly.

Installing the Foam and Paper Elements

Important

To prevent engine damage, always operate

the engine with the complete foam and paper air cleaner

assembly installed.

1. Place the foam element and paper element into the

blower housing.

Note: Make sure that the rubber seal is flat against the air

cleaner base.

2. Align the tabs on the air cleaner cover with the slots of

the blower housing (Fig. 21). Hook the handle onto the

cover and press down on the handle to lock the cover

in place.

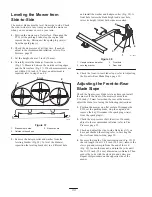

Servicing the Spark Plug

Replace the spark plug after every 100 operating hours.

Make sure that the air gap between the center and side

electrodes is correct before installing the spark plug. Use a

spark plug wrench for removing and installing the spark

plug(s) and a gapping tool/feeler gauge to check and

adjust the air gap. Install a new spark plug if necessary.

Type: Champion RC12YC (or equivalent)

Air Gap: 0.030 inch (0.76 mm)