26

2. Check the balance of the blade by putting it on a blade

balancer (Fig. 29). If the blade stays in a horizontal

position, the blade is balanced and can be used. If the

blade is not balanced, file some metal off the end of

the sail area only (Fig. 27). Repeat this procedure until

the blade is balanced.

1

2

m–1855

Figure 29

1.

Blade

2.

Balancer

Installing the Blades

1. Install the blade onto the spindle shaft (Fig. 27).

Important

The curved part of the blade must be

pointing upward toward the inside of the mower to ensure

proper cutting.

2. Install the curved washer (cupped side toward the

blade) and blade bolt (Fig. 27). Torque the blade bolt

to 35–65 ft.-lb. (47–88 N

⋅

m).

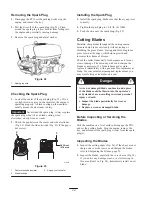

Greasing and Lubrication

Lubricate the machine when shown on the Check Service

Reference Aid decal (Fig. 30) located beneath the seat.

Grease more frequently when operating conditions are

extremely dusty or sandy.

Grease with No. 2 general purpose lithium base or

molybdenum base grease.

How to Grease

1. Disengage the PTO, stop the engine, and remove the

key.

2. Clean the grease fittings with a rag. Make sure to

scrape any paint off of the front of the fitting(s).

3. Connect a grease gun to the fitting. Pump grease into

the fittings until grease begins to ooze out of the

bearings.

4. Wipe up any excess grease.

Where to Add Grease

Lubricate the grease fittings as shown on the Check

Service Reference Aid decal (Fig. 30) located beneath the

seat.

Figure 30

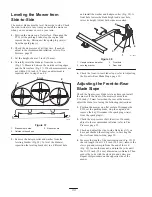

Greasing the Bearings

The cutting unit must be lubricated regularly; refer to the

Recommended Maintenance Schedule, page 20. Grease

with No. 2 general purpose lithium base or molybdenum

base grease.

1. Stop the engine, set the parking brake, remove the key,

and disconnect the spark plug wire(s) from the spark

plug(s).

2. Grease the idler pulley pivot (Fig. 31).

m–5157

Figure 31

Top View