33

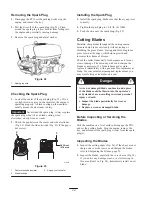

4. Remove the hairpin cotter and washer from the rear

trunion rod (Fig. 45) on each side of the mower.

5. Remove the hairpin cotter and washer at the mower

leveling brackets (Fig. 45) on each side of the mower.

Note which hole the leveling bracket is mounted in for

future installation. Slide the brackets off of the

mounting pin.

m–5177

1

3

4

2

Figure 45

1.

Hairpin cotter and washer

2.

Rear trunion rod

3.

Hairpin cotter and washer

4.

Leveling bracket

6. Slide the mower rearward to remove the mower belt

from the engine pulley.

7. Slide the mower out from underneath the tractor.

Note: Retain all parts for future installation.

Installing the Mower

1. Park the machine on a level surface, disengage the

PTO, set the parking brake, stop the engine, and

remove the key. Disconnect the spark plug wire(s)

from the spark plug(s).

2. Slide the mower under the tractor.

3. Lower the height-of-cut lever to the lowest position.

4. Attach the rear trunion rod to the tractor with the

washer and hairpin cotter (Fig. 45) on each side of the

mower.

5. Slide the leveling brackets onto the mounting pins and

secure them with the washers and hairpin cotters

(Fig. 45).

6. Attach the front trunion rods to the tractor with the

clevis pins and hairpin cotters (Fig. 44).

7. Install the mower belt onto the engine pulley; refer to

Replacing the Mower Belt, page 32.

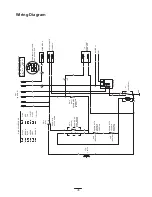

Fuse

The electrical system is protected by fuses. It requires no

maintenance; however, if a fuse blows, check the

component/circuit for a malfunction or short.

Fuse: Main F1—30 amp, blade-type

Charge Circuit F2—25 amp, blade-type

Optional Headlight Kit—10 amp, blade type

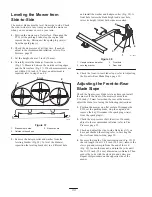

1. Raise the seat to gain access to the fuse holder

(Fig. 46).

2. To replace a fuse, pull out on the fuse to remove it

(Fig. 46).

m–5144

1

2

3

Figure 46

1.

Main—30 amp

2.

Charge circuit—25 amp

3.

For optional Headlight

Kit—10 amp

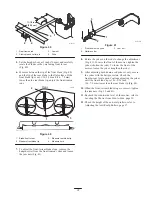

Washing the Underside of the

Mower

After each use, wash the underside of the mower to

prevent grass buildup for improved mulch action and

clipping dispersal.

1. Park the machine on a hard level surface, disengage

the PTO, stop the engine, and remove the ignition key.

2. Attach the hose coupling to the end of the mower

washout fitting, and turn the water on high (Fig. 47).

Note: Spread petroleum jelly on the washout fitting o-ring

to make the coupling slide on easier and protect the

o-ring.