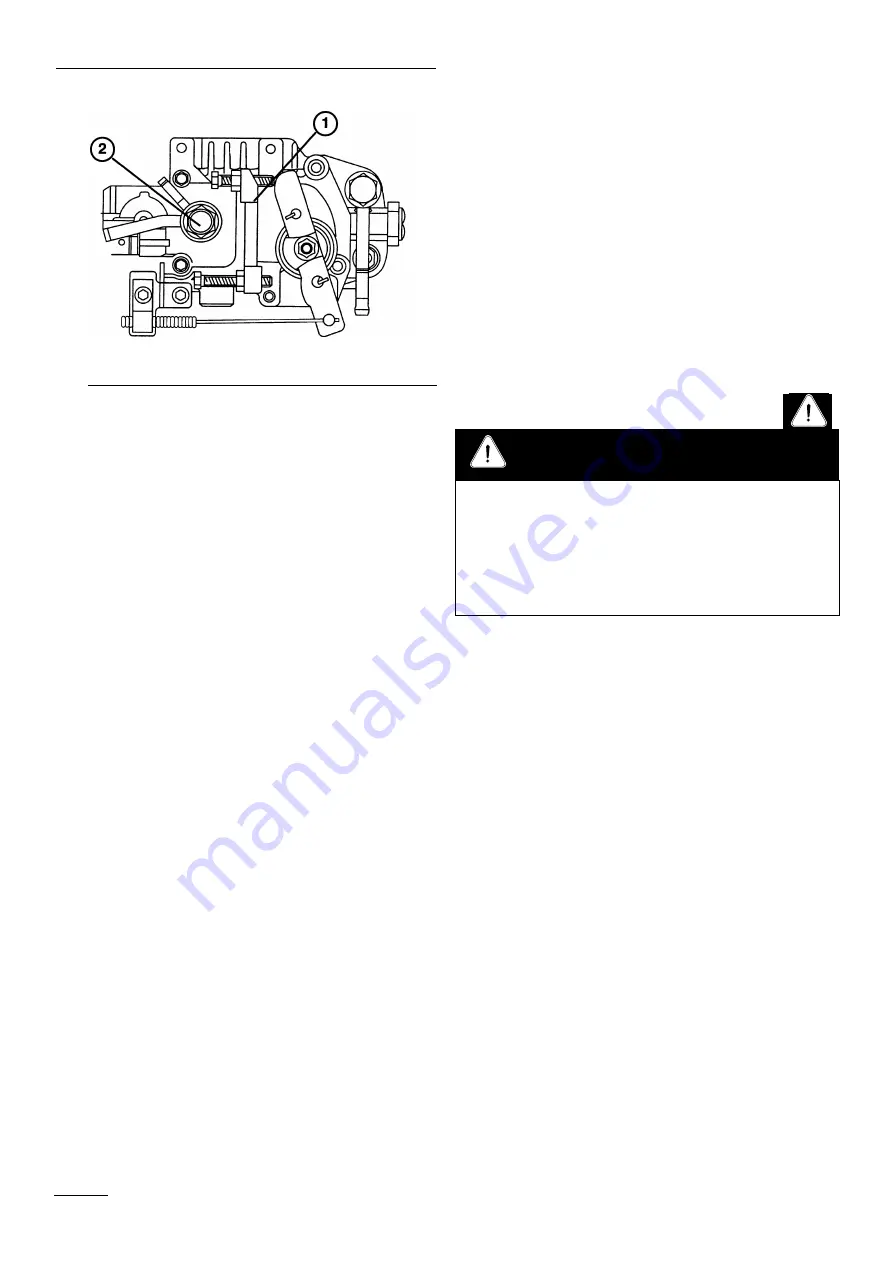

Figure 16

1. Fuel injection pump

2. Air bleed screw

OPERATING THE POWER TAKE

OFF (PTO)

The power take off (PTO) switch engages and

disengages power to the electric clutch.

Engaging the PTO

1.

Release the parking brake.

2.

Release pressure on the traction pedal to stop

movement.

3.

To engage, lift the cover and move the PTO switch

forward to the “ON” position.

Disengaging the PTO

Closing the cover moves the PTO switch to the “OFF”

(disengaged) position.

DRIVING FORWARD OR

BACKWARD

Place the throttle control in the 3/4 position for best

performance.

Forward

1.

To go forward, place your foot on the traction pedal.

2.

Release the parking brake.

3.

Slowly press on the upper pad of the traction

control to move forward.

Backward

1.

To go backward, place your foot on the traction

pedal.

2.

Release the parking brake.

3.

Slowly press on the lower pad of the traction pedal

to move rearward.

CHECK OPERATION OF

INTERLOCK SWITCHES

1.

With the operator off the seat, the traction pedal in

neutral and the PTO switch in the disengage

position, the engine should start. If either the

traction pedal is depressed or the PTO switch is

engaged, the engine should stop. Correct the

problem if the system is not operating properly.

2.

With the operator in the seat, the parking brake

engaged and the engine running, depress the

traction pedal either forward or reverse. The engine

should stop. Correct the problem if the system is not

operating properly.

3.

With the operator in the seat, the parking brake

engaged and engine running, lower the cutting units

to the ground. Engage the PTO switch, the electric

clutch on the engine should engage. Raise the

cutting units, the PTO switch should disengage.

Correct the problem if the system is not operating

properly.

IMPLEMENT LIFT LEVER

Operation

18

Do not disconnect the safety switches because they are

for the operator’s protection. Check switch operation

daily to be sure the system is operating correctly. If a

switch is not operating correctly, replace it before

operating the machine. Replace the switches every two

years to be sure of maximum safety.

CAUTION

Summary of Contents for 2003

Page 16: ...Figure 15 1 Fuel valve Controls 16 1 ...

Page 24: ...Figure 25 Figure 26 Figure 27 Figure 28 Figure 29 Figure 30 Figure 31 24 Maintenance ...

Page 34: ......

Page 35: ......

Page 36: ......