7

Setup

Note: Determine the left and right sides of the machine

from the normal operating position.

Installing the Handle

1. Align the upper and lower handle sections, and remove

the packing filler between them with a pliers.

2. Remove the left knob and bolt (Fig. 2).

311

2

1

Figure 2

1.

Left handle knob (before

moving it on the inside)

2.

Right handle knob

3. Install the left knob on the inside of the handle (Fig. 2).

4. Tighten both handle knobs.

5. Move the handle support brackets slightly outward so

that they will not be in the way when you move the

handle backward into the operating position (Fig. 3).

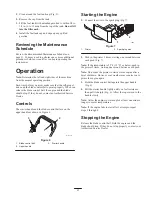

m-4271

4

1

2

3

Figure 3

1.

Support bracket

2.

Handle stud

3.

Control cable

4.

Cable tie

6. Move the handle backward.

7. Move the support brackets inward while you position

the handle studs into the center hole of the brackets

(Fig. 3).

Note: If the handle height is not satisfactory, adjust it by

placing the handle stud into a different hole.

8. Secure the cable to the upper handle section with a

cable tie (Fig. 3).

Installing the Starter Rope

Pull the starter rope through the rope guide on the handle

(Fig. 4).

210

2

1

Figure 4

1.

Rope guide

2.

Starter rope

Before Starting

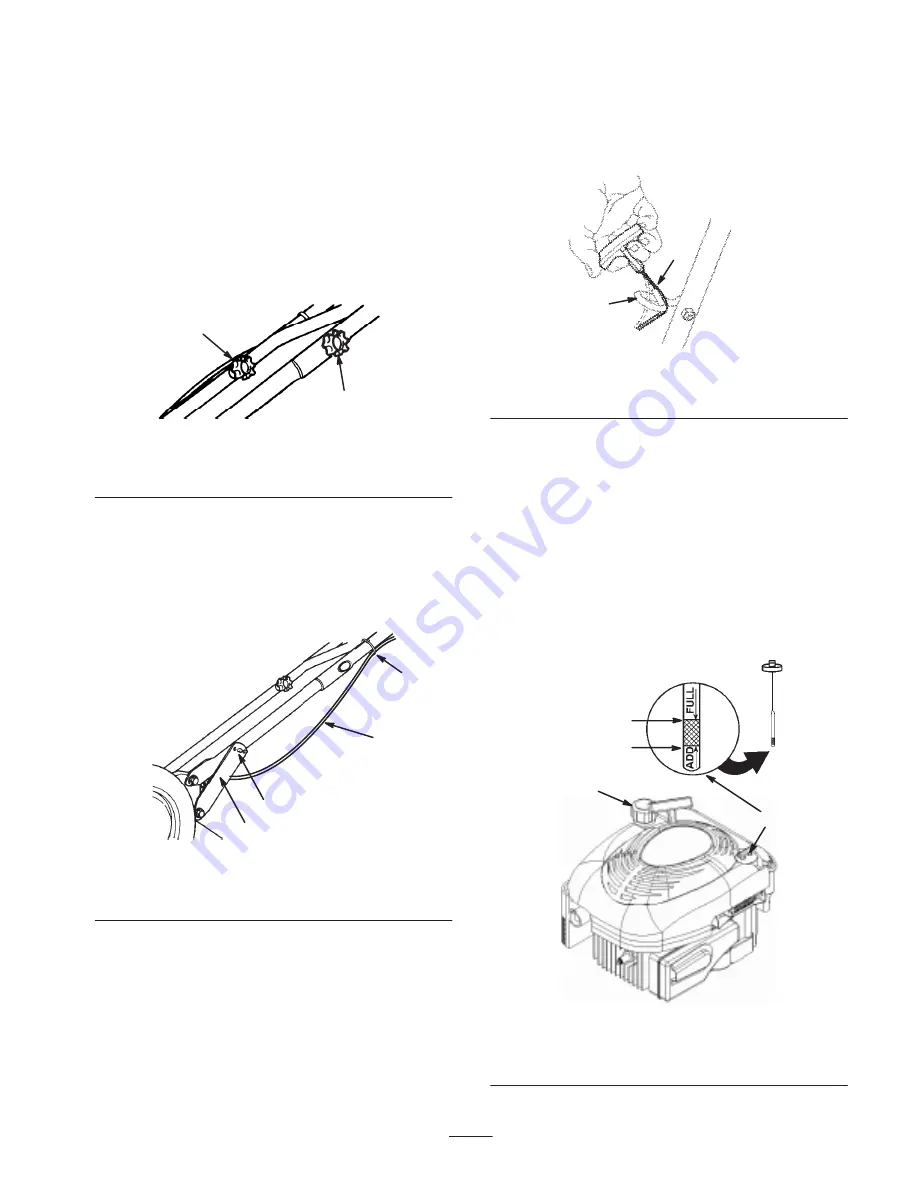

Filling the Crankcase with Oil

The crankcase can hold 20 ounces (0.59 liters) of oil. Use

only high-quality, SAE 30 weight detergent oil that has the

American Petroleum Institute (API) service classification

SF, SG, SH, or SJ.

Before each use, ensure that the oil level is between the

Add and the Full marks on the dipstick (Fig. 5).

1626

3

2

1

4

Figure 5

1.

Dipstick

2.

Add mark

3.

Full mark

4.

Fuel tank cap