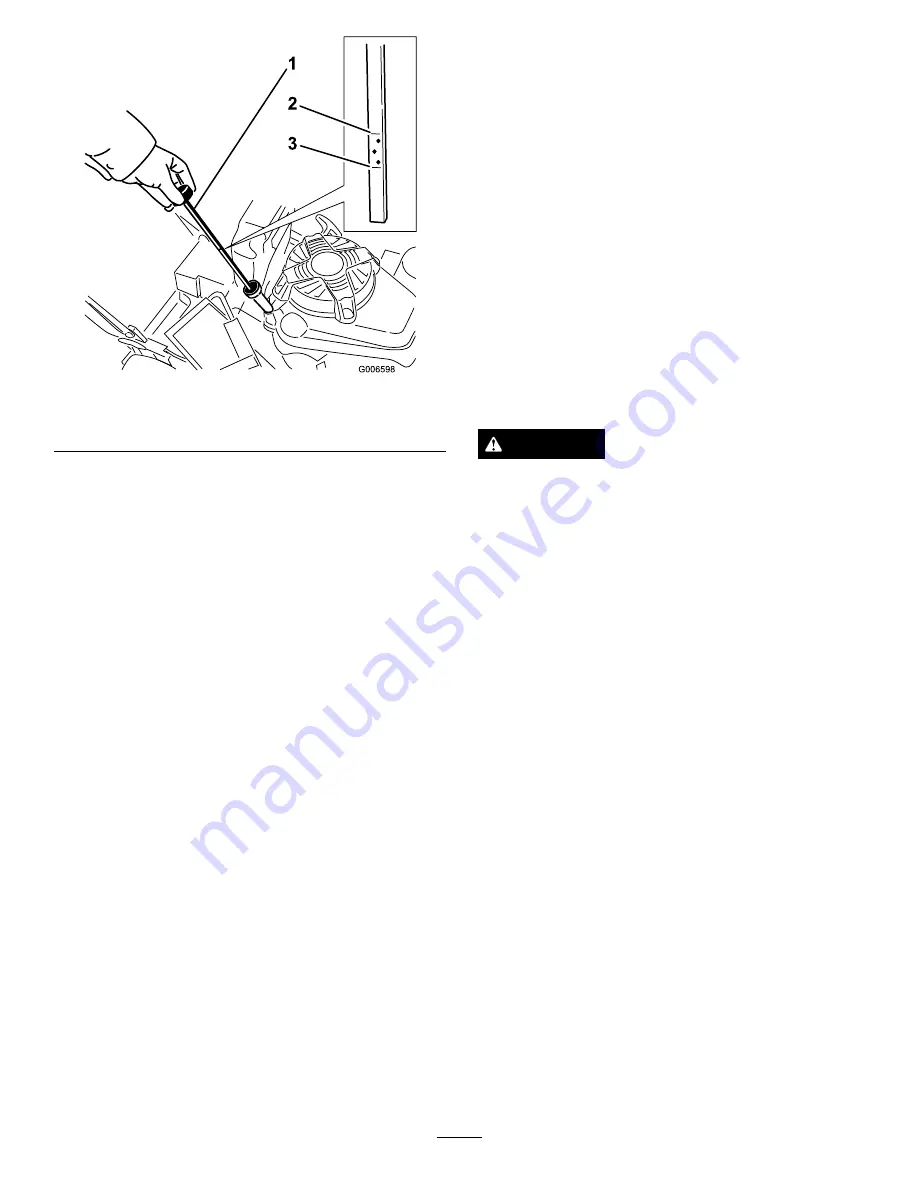

Figure 10

1.

Dipstick

3.

Add

2.

Full

Note:

When the crankcase is empty, pour about 3/4

of the crankcase capacity of oil in the crankcase, then

follow the procedure in this section.

1. Move the lawn mower to a level surface.

2. Clean around the dipstick (Figure 11).

3. Remove the dipstick by rotating the cap

counterclockwise and pulling it out.

4. Wipe the dipstick clean with a clean cloth.

5. Insert the dipstick into the filler neck, then remove

it.

Note:

To ensure an accurate oil level reading, you

must fully install the dipstick.

6. Read the oil level on the dipstick (Figure 11).

7. If the oil level reading is below the Add mark on

the dipstick, slowly pour only enough oil into the

filler hole to raise the oil level to the Full mark on

the dipstick.

Important:

Do not overfill the crankcase with

oil and run the engine; engine damage will

result. Drain the excess oil until the oil level on

the dipstick reads Full.

8. Insert the dipstick into the filler neck and rotate the

cap clockwise until it is tight.

Filling the Fuel Tank with

Gasoline

For best results, use clean, fresh, lead-free gasoline with

an octane rating of 87 or higher. To ensure freshness,

purchase only the quantity of gasoline that you expect to

use in 30 days. Using unleaded gasoline results in fewer

combustion deposits and longer engine life. You may

use leaded gasoline if unleaded gasoline is not available.

Important:

Do not add oil to the gasoline.

Important:

Do not use methanol, gasoline

containing methanol, gasohol containing more

than 10% ethanol, premium gasoline, or white gas.

Using these fuels can damage the engine’s fuel

system.

Important:

Do not use gasoline that has been

stored since the last mowing season or longer.

DANGER

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or explosion

from gasoline can burn you and others and can

damage property.

•

Fill the fuel tank outdoors, in an open area, and

when the engine is cold. Wipe up any gasoline

that spills.

•

Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1/4 to

1/2 in. (6 to 13 mm) below the bottom of the

filler neck. This empty space in the tank allows

the gasoline to expand.

•

Never smoke when handling gasoline, and stay

away from an open flame or where a spark may

ignite the gasoline fumes.

•

Store gasoline in an approved fuel container

and keep it out of the reach of children.

•

Never buy more than a 30-day supply of

gasoline.

11