Maintenance

29

4.

Remove and inspect fuel filter. Replace if dirty.

5.

Re–install bowl to filter head. Make sure O–ring

is positioned properly between bowl mounting

nut and filter head.

6.

Open fuel shut–off on filter.

7.

Open bleed screws on filter mounting head to

re–fill bowl with fuel. Close bleed screws.

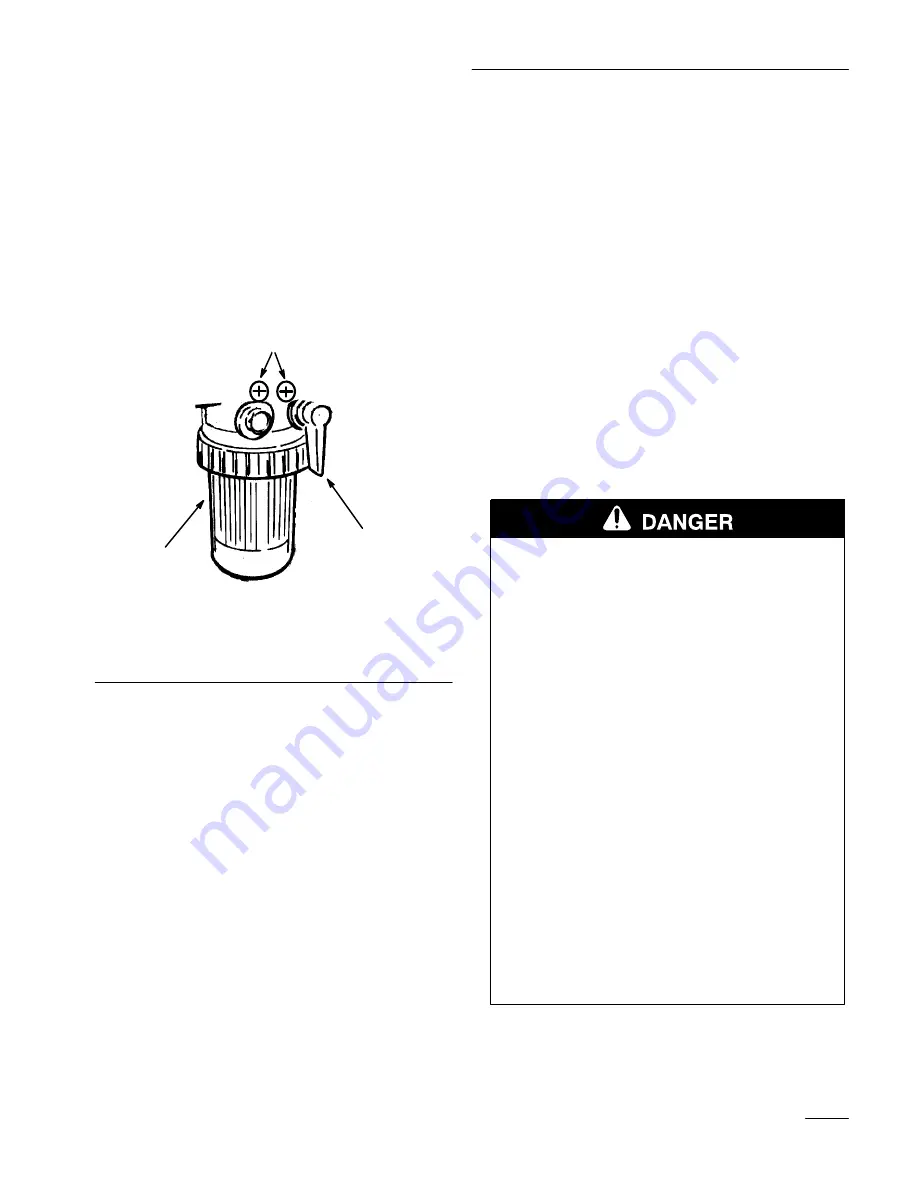

1

2

3

Figure 13

1.

Filter

2.

Fuel shut–off

3.

Bleed screws

Bleeding Fuel System

Bleeding of the fuel system is required if:

•

Initial start up of a new machine or a machine

that has been stored.

•

Engine has ceased running due to lack of fuel.

•

Maintenance has been performed on fuel system

components.

1.

Park the machine on a level surface. Make sure

fuel tank is at least half full.

2.

Lower the loader arms and turn the ignition key

to “OFF” to stop the engine. Remove the key.

3.

Open fuel shut–off on fuel filter and open fuel

cap vent.

POTENTIAL HAZARD

•

Under certain conditions fuel is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

•

A fire or explosion from fuel can burn you,

others, and cause property damage.

HOW TO AVOID THE HAZARD

•

Use a funnel and fill the fuel tank outdoors,

in an open area, when the engine is cold.

Wipe up any fuel that spills.

•

Do not fill the fuel tank completely full.

Add fuel to the fuel tank until the level is

1/4” to 1/2” (6 mm to 13 mm) below the

bottom of the filler neck. This empty space

in the tank allows fuel to expand.

•

Never smoke when handling fuel, and stay

away from an open flame or where fuel

fumes may be ignited by a spark.

•

Store fuel in an approved container and

keep it out of the reach of children. Never

buy more than a 30-day supply.