Maintenance

26

Greasing and Lubrication

Grease all pivot joints every 25 operating hours.

Grease every 8 hours when operating conditions are

extremely dusty or sandy and immediately after every

washing.

Grease Type: General-purpose grease.

How to Grease

1.

Lower the loader arms and turn the ignition key

to “OFF” to stop the engine. Remove the key.

2.

Clean the grease fittings with a rag.

3.

Connect a grease gun to the fitting. Pump grease

into the fittings until grease begins to ooze out of

the bearings.

4.

Wipe up any excess grease.

Lubricating Traction Drive Chain

1.

Lower the loader arms and turn the ignition key

to “OFF” to stop the engine. Remove the key.

2.

Apply a general purpose oil (10W30) onto upper

and lower chain spans.

3.

Start the machine and slowly move it forward to

expose un–lubed upper and lower chain spans.

4.

Turn the ignition key to “OFF” to stop the

engine. Remove the key.

5.

Apply oil to newly exposed un–lubed chain

spans.

Fuel Filter

Replace the fuel filter after every 200 operating hours

or yearly, whichever occurs first.

Replacing the Fuel Filter

Never re–install a dirty filter.

1.

Lower the loader arms and turn the ignition key

to “OFF” to stop the engine. Remove the key.

2.

Shut off the fuel valve on the bottom of the fuel

tank.

3.

Clamp fuel line between fuel tank and fuel filter

to block fuel flow.

4.

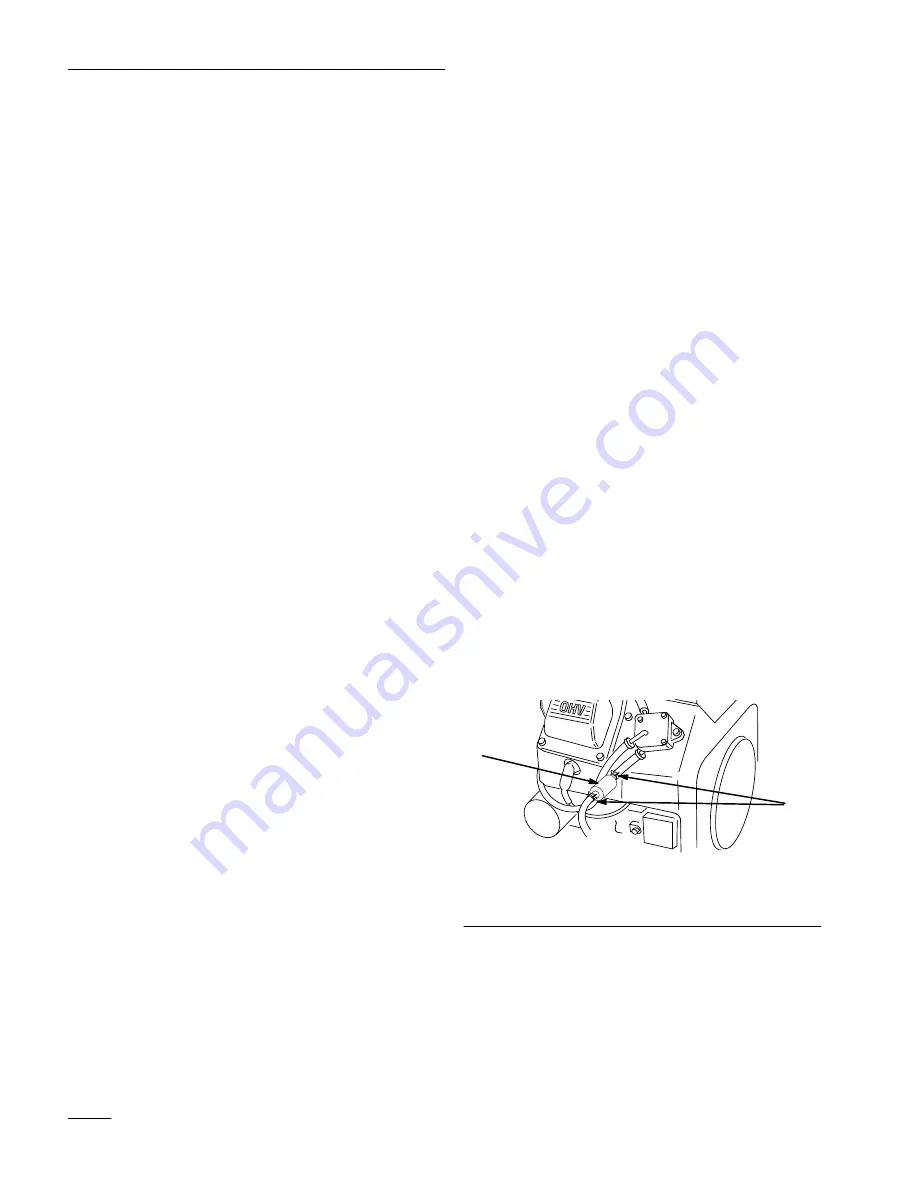

Squeeze the ends of the hose clamps together

and slide them away from the filter (Fig. 16).

5.

Place a drain pan under the fuel lines to catch

any leeks, then remove the filter from the fuel

lines.

6.

Install a new filter and move the hose clamps

close to the filter.

7.

Remove clamp blocking fuel flow and open the

fuel valve.

1

2

m–3217

Figure 16

1.

Filter

2.

Hose clamp

Summary of Contents for 22304

Page 7: ...Safety 5 Slope Chart Read all safety instructions on pages 2 4 ...

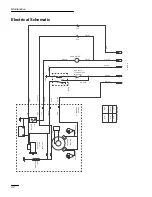

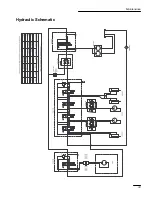

Page 35: ...Maintenance 33 Hydraulic Schematic ...

Page 38: ... ...

Page 39: ... ...