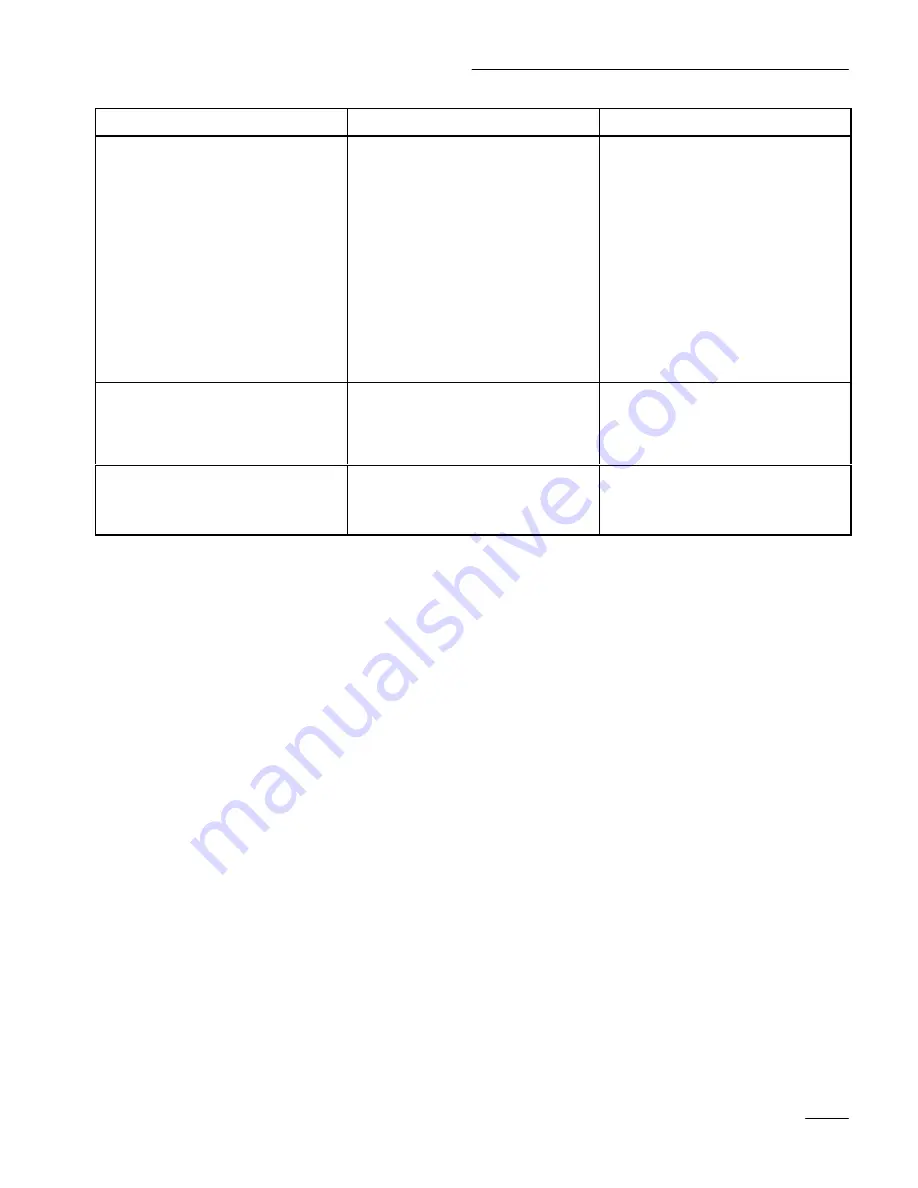

Troubleshooting

35

PROBLEM

CORRECTIVE ACTION

POSSIBLE CAUSES

Machine does not drive.

1.

Flow divider valve lever is in

9 o’clock position.

1.

Move lever to the 12 to 10

o’clock position.

2.

Hydro fluid level low.

3.

Traction pump drive coupler

is loose or broken.

4.

Pump and/or wheel motor is

defective or damaged.

5.

Control valve is defective or

damaged.

6.

Relief valve is defective or

damaged.

2.

Add hydro fluid to reservoir.

3.

Contact Service Dealer.

4.

Contact Service Dealer.

5.

Contact Service Dealer.

6.

Contact Service Dealer.

When at rest, loader arms creep

downward more than 3” per hour

(less than 3” an hour is normal for

this machine).*

1.

Valve spool leakage

1.

Contact Service Dealer.

When at rest, loader arms settle

downward 2” quickly and then

stop.*

1.

Cylinder seals are leaking

2.

Cylinder rephase valve is

leaking

1.

Replace seals.

2.

Contact Service Dealer.

* Tested with warm oil and no more than 515 lbs in the bucket. Measure the downward drop at the attachment

lock pins on the back of the mount plate.

Summary of Contents for 22304

Page 7: ...Safety 5 Slope Chart Read all safety instructions on pages 2 4 ...

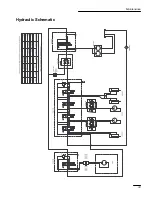

Page 35: ...Maintenance 33 Hydraulic Schematic ...

Page 38: ... ...

Page 39: ... ...