between attempts. Failure to follow these

instructions can burn out the starter motor.

6. Move the throttle lever to desired setting.

Important:

If the engine is run at high speeds

when the hydraulic system is cold (i.e., when

the ambient air temperature is near freezing or

lower), hydraulic system damage could occur.

When starting the engine in cold conditions,

allow the engine to run in the middle throttle

position for 2 to 5 minutes before moving the

throttle to fast (rabbit).

Note:

If outdoor temperature is below freezing,

store the traction unit in a garage to keep it warmer

and aid in starting.

Stopping the Engine

1. Move the throttle lever to the slow (turtle) position.

2. Lower the loader arms to the ground.

3. Turn the ignition key off.

Note:

If the engine has been working hard or

is hot, let it idle for a minute before turning the

ignition key off. This helps cool the engine before

it is stopped. In an emergency, the engine may be

stopped immediately.

Stopping the Traction Unit

To stop the traction unit, release the traction control,

move the throttle lever to slow (turtle), lower loader

arms to the ground, and stop the engine. Set the

parking brake and remove the key.

A child or untrained bystander could attempt to

operate the traction unit and be injured.

Remove the key from the switch when leaving

the traction unit, even if just for a few seconds.

Moving a Non-functioning

Traction Unit

Important:

Do not tow or pull the traction

unit without first opening the tow valves, or the

hydraulic system will be damaged.

1. Stop the engine.

2. Open the rear access cover.

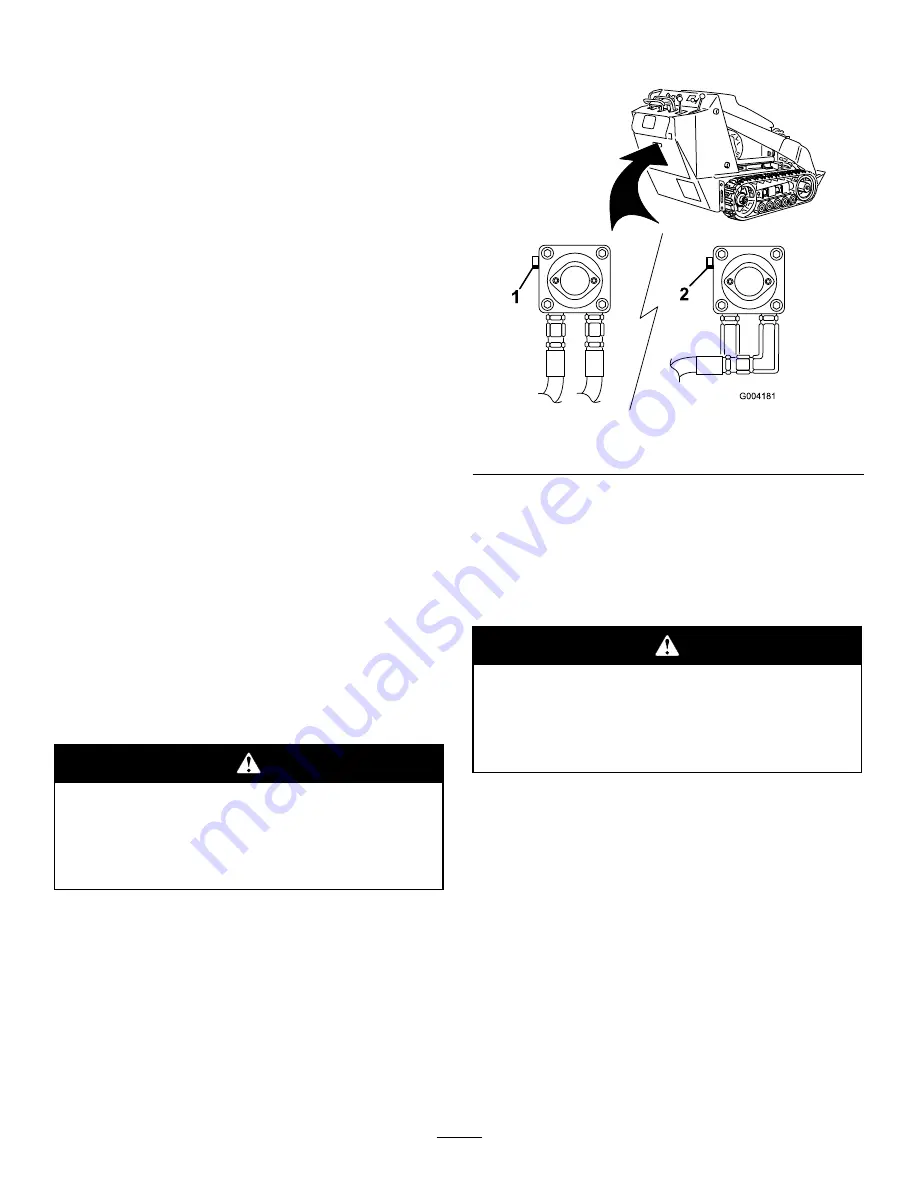

3. Using a wrench, turn the tow valves on the hydraulic

pumps twice counter-clockwise (Figure 22).

Figure 22

1.

Left tow valve (right track)

2.

Right tow valve (left track)

4. Tow the traction unit as required.

5. When the traction unit has been repaired, close the

tow valves before operating it.

Using the Cylinder Lock

The loader arms may lower when in the raised

position crushing anyone under them.

Install the cylinder lock before performing

maintenance that requires raised loader arms.

Installing the Cylinder Lock

1. Remove the attachment.

2. Raise the loader arms to the fully raised position.

3. Stop the engine.

4. Remove the lynch pin securing the cylinder lock to

the loader arm (Figure 23).

22

Summary of Contents for 22319

Page 7: ...Slope Indicator 7...

Page 49: ...Schematics G007388 Electrical Schematic Rev B 49...

Page 50: ...Hydraulic Schematic Rev A 50...

Page 51: ...Notes 51...