Replacing Narrow-Width Tracks

Replace the tracks when they are badly worn.

Note:

You have narrow-width tracks if the tracks are less

than 15.5 cm (6 inches) wide.

1.

Park the machine on a level surface, engage the parking

brake, and lower the loader arms.

2.

Shut off the engine and remove the key.

3.

Lift/support the side of the machine that you will work

on so that the track is 7.6 to 10 cm (3 to 4 inches) off

the ground.

4.

Remove the locking bolt and nut (

5.

Using a 1/2-inch drive ratchet, release the drive tension

by turning the tensioning screw clockwise (

and

).

g029759

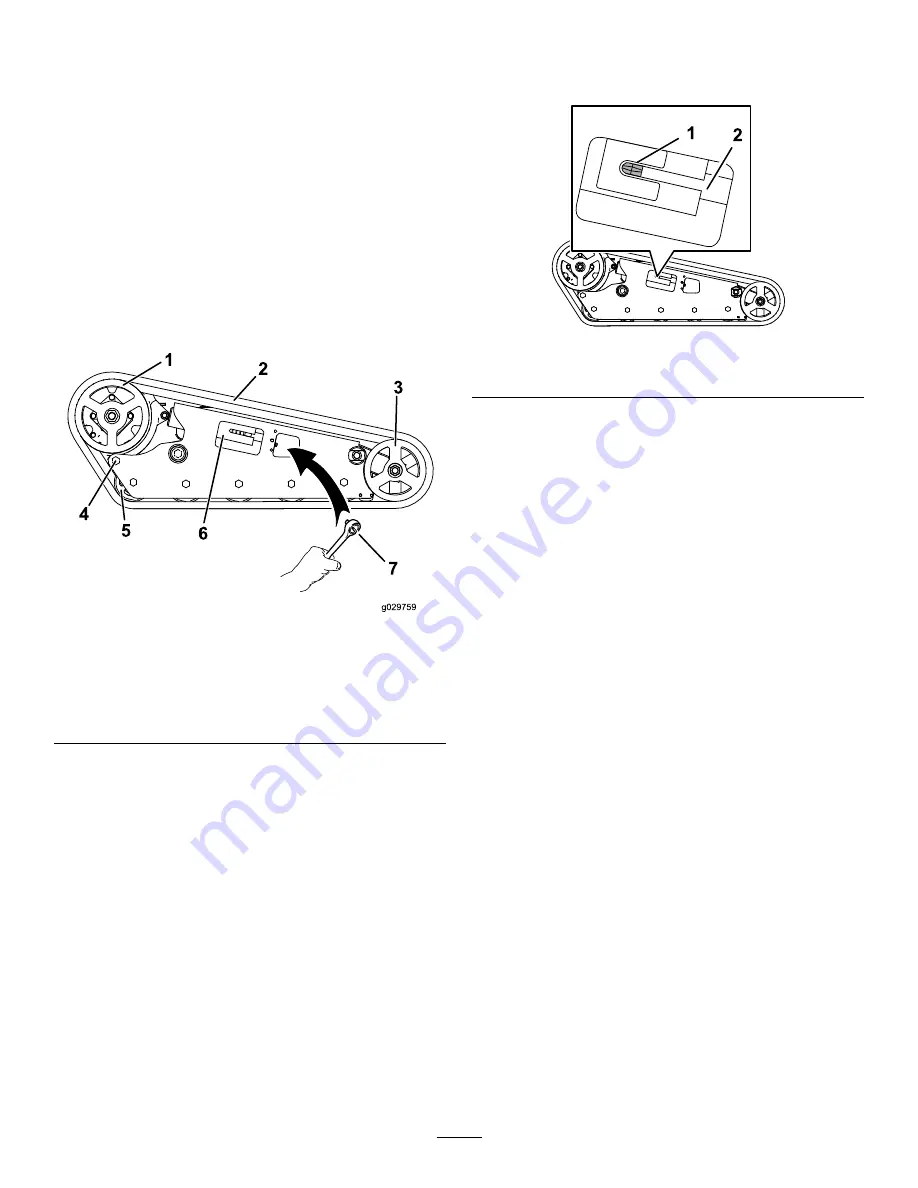

Figure 60

1.

Drive sprocket

5.

Road wheel

2.

Track

6.

Pivot tensioner

3.

Front wheel

7.

Ratchet (1/2 inch)

4.

Rear bolt

6.

Loosen the rear bolt, near the drive wheel (

).

Note:

This enables the drive wheel to pivot forward

and release the tension of the track. If it does not

pivot, turn on the engine and briefly move the traction

control forward.

7.

Remove the track at the top of the front wheel, peeling

it off the wheel while rotating the track forward.

8.

When the track is off the front wheel, remove it from

the drive sprocket and road wheels (

9.

Beginning at the drive sprocket, coil the new track

around the sprocket, ensuring that the lugs on the track

fit between the spacers on the sprocket (

10.

Push the track under and between the road wheels

(

).

11.

Starting at the bottom of the front wheel, install the

track around the wheel by rotating the track rearward

while pushing the lugs into the wheel.

12.

Using a 1/2 inch drive ratchet, turn the tensioning

screw counter-clockwise until the tensioning screw

bottoms out (

g203963

Figure 61

1.

Tension nut

2.

Tension screw

13.

Align the closest notch in the tension screw to the

locking bolt hole and secure the screw with the locking

bolt and nut.

14.

Torque the rear bolt to 108 to 122 N∙m (80 to 90 ft-lb).

15.

Lower the machine to the ground.

16.

Repeat the procedure to replace the other track.

17.

Drive the machine, then park the machine on a level

surface, engage the parking brake, shut off the engine,

and remove the key.

18.

Verify that the tension screw is bottomed out.

Note:

The track tension loosens after some use.

19.

Adjust the track tension so that the tension block aligns

with the green guide on the decal or is 1.3 cm (1/2

inch) away from the rear of the tension tube slot; refer

to

Adjusting the Track Tension (page 39)

.

40

Summary of Contents for 22327

Page 54: ...Schematics g205307 Electrical Schematic Rev B 54...

Page 55: ...g206362 Hydraulic Schematic Rev B 55...

Page 56: ...Notes...

Page 57: ...Notes...

Page 58: ...Notes...