12

12.

Slide the hydraulic motor and motor housing into

position and secure it with the bolts removed in step 2.

13.

Install the side guard and secure it with the bolts

removed in step 1.

Replacing the Castor Fork

Bushings

After many hours of operation, the bushings pressed into

the top and bottom of the frame bracket will wear. To

check the bushings, move the castor fork fore and aft and

from side to side. If the castor spindle is loose in the

bushings, the bushings are worn and must be replaced.

1.

Start the engine and raise the broom to highest

possible position.

2.

Install the cylinder locks then stop the engine.

3.

Remove the cap and thrust washers from top of castor

spindle.

4.

Pull the castor spindle out of the bracket, allowing the

thrust washers to remain on the bottom of the spindle.

5.

Using a pin punch, drive the bushings out of the

bracket (Fig. 22).

1

2

2

Figure 22

1. Frame bracket

2. Bushing

6.

Clean inside of the bracket to remove any dirt.

7.

Apply grease to the inside and outside of the new

bushings.

8.

Using a hammer and a flat plate, drive the bushings

into the bracket (Fig. 22)

9.

Inspect the castor shaft for wear and replace it if

necessary.

10.

Install the castor spindle into the bracket, place the

thrust washers onto the spindle, and secure it with the

cap.

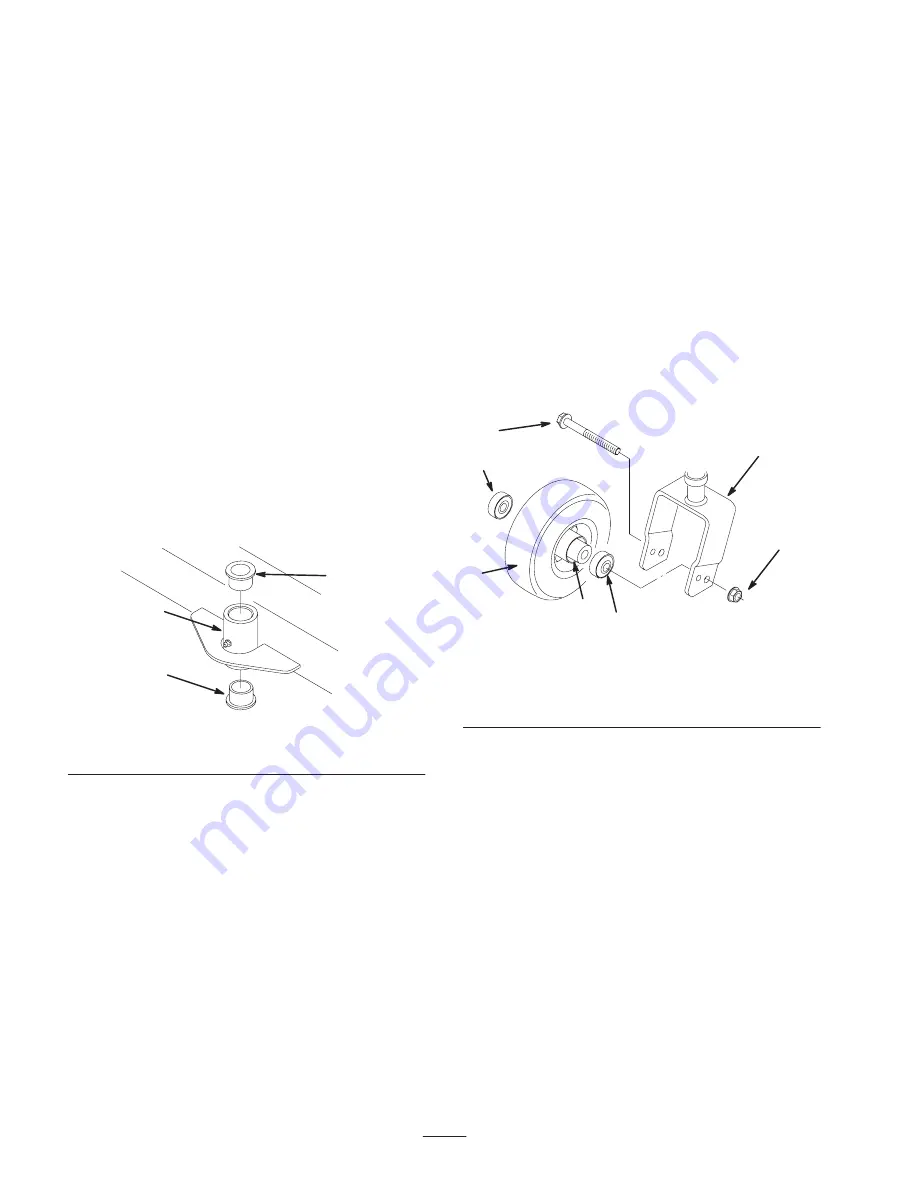

Servicing a Castor Wheel

When a castor wheel becomes wobbly, it usually indicates

that the wheel bearings are worn. Perform this procedure

to fix a wobbly castor wheel.

1.

Start the engine and raise the broom to highest

possible position.

2.

Install the cylinder locks then stop the engine.

3.

Remove locknut and capscrew that secure the castor

wheel assembly in the castor fork

(Fig. 23).

4.

Remove the castor wheel from the fork (Fig. 23).

5.

Remove the outer bearing from wheel hub and allow

the bearing spacer to fall out (Fig. 23).

6.

Remove the other outer bearing (Fig. 23).

3

5

2

6

5

4

1

Figure 23

1. Castor fork

2. Castor wheel

3. Capscrew

4. Locknut

5. Outer bearing

6. Bearing spacer

7.

Check the bearings, spacer, and inside of wheel hub

for wear. Replace any defective parts.

8.

Push an outer bearing into the wheel hub.

9.

Slide the bearing spacer into the wheel hub.

10.

Push other bearing into the open side of the wheel hub

to captivate the spacer inside.

11.

Install castor wheel assembly in the castor fork and

secure it in place with a capscrew and locknut.

Storage

1.

Before long term storage wash the attachment with

mild detergent and water to remove dirt and grimee.

2.

Check the condition of the brushes and replace if

necessary.

3.

Apply grease to all grease fittings.