Operating the Mower Blade

Control Knob (PTO)

The blade control knob (PTO) is used in conjunction with

the Operator Presence Control (OPC) levers to engage and

disengage the mower blades.

Engaging the Mower Blades (PTO)

1.

To engage blades, squeeze the Operator Presence

Control (OPC) levers against handle grips (Figure 12).

2.

Pull blade control knob (PTO) up. Hold the OPC

levers against handle grip.

Note:

The engine will kill if the OPC levers are

released with the mower running and the speed control

lever is not in neutral.

3.

Restart the engine and repeat the procedure to engage

the mower blades if the operator presence control

(OPC) levers are released.

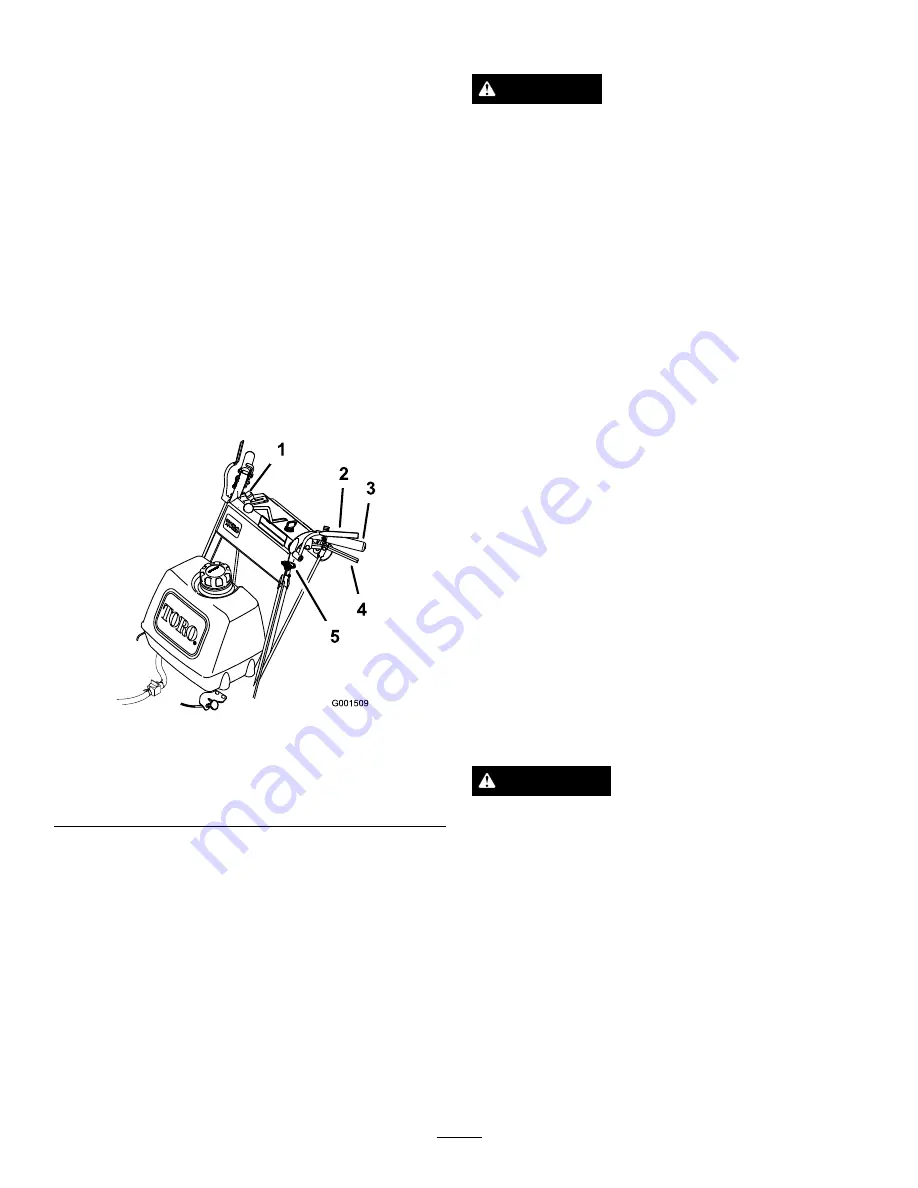

Figure 12

1.

Throttle lever

4.

Drive Lever

2.

Operator Presence

Control levers (OPC)

5.

Blade control knob (PTO)

3.

Handle

Disengaging the Mower Blades (PTO)

The mower blades can be disengaged by one of the following

steps.

1.

Push the blade control knob (PTO) down to off

(Figure 12).

2.

Releasing the Operator Presence Control (OPC) levers

will kill the engine and stop the blades (Figure 12) with

the blade control lever engaged.

The Safety Interlock System

CAUTION

If safety interlock switches are disconnected or

damaged the machine could operate unexpectedly

causing personal injury.

•

Do not tamper with the interlock switches.

•

Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

Understanding the Safety Interlock

System

The safety interlock system is designed to prevent the mower

from starting unless:

•

The blade control knob (PTO) is pushed off.

•

The speed control lever is in neutral.

The safety interlock system is designed to kill the engine

when:

•

The Operator Presence Control (OPC) levers are released

with the mower engaged and/or the speed control is out

of neutral.

•

The speed control lever is shifted out of neutral without

holding OPC levers or with the brake engaged.

•

The blade control knob (PTO) is pulled up without

holding the OPC levers.

Testing the Safety Interlock System

Service Interval:

Before each use or daily

Test the safety interlock system before you use the machine

each time. If the safety system does not operate as described,

have an Authorized Service Dealer repair the safety system

immediately.

WARNING

While testing the safety interlock system, the

machine may move forward and cause personal

injury or property damage.

•

Perform the safety interlock test in an open area.

•

Ensure no one is standing in front of the

machine while performing the safety interlock

test.

1.

Set the neutral locks and place speed control lever in

neutral.

2.

Start the engine; refer to Starting and Stopping the

Engine.

3.

Without holding the Operator Presence Control (OPC)

levers, pull the blade control knob (PTO) up. The

engine should kill.

16

Summary of Contents for 30934

Page 49: ...Schematics Electrical Schematic Rev Hydraulic Schematic Rev 49 ...

Page 50: ...Notes 50 ...

Page 51: ...Notes 51 ...