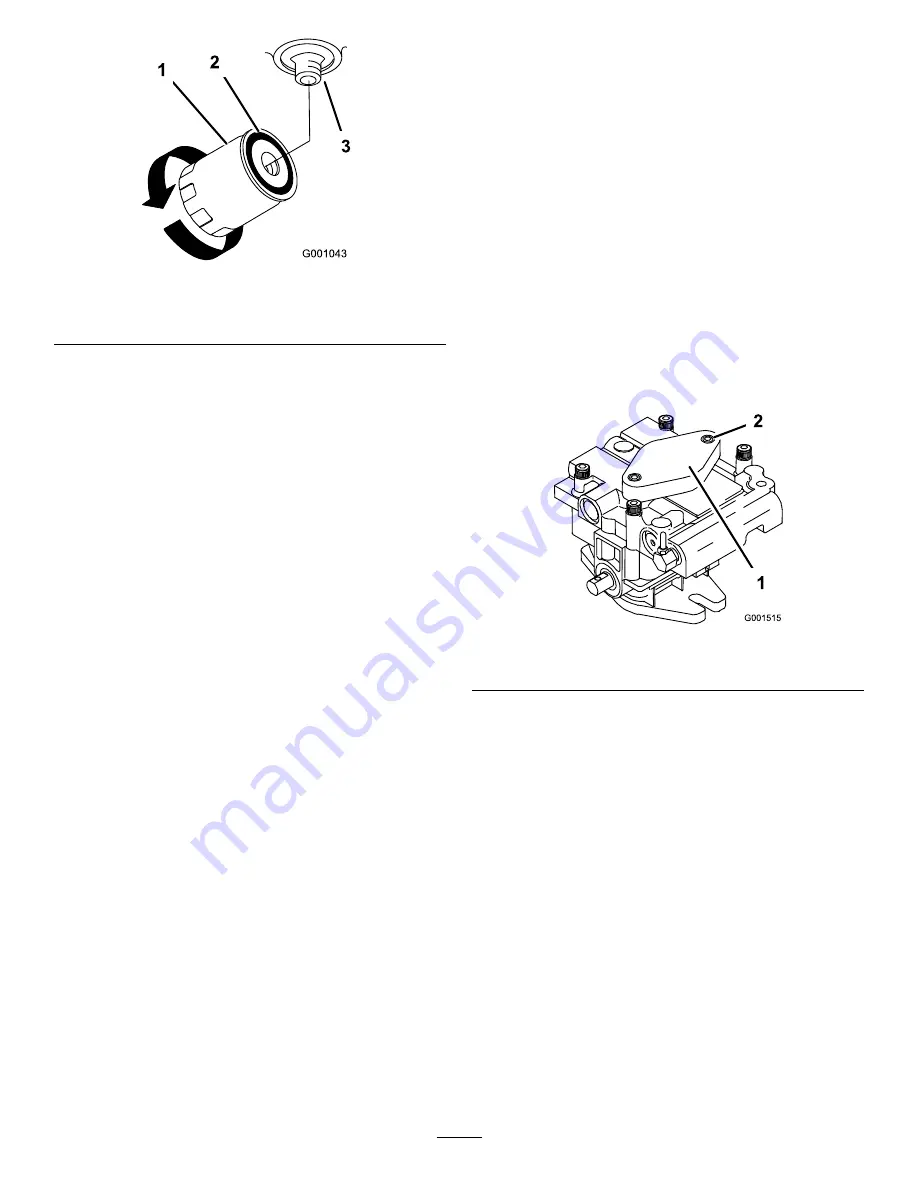

Figure 61

1.

Hydraulic filter

3.

Adapter

2.

Gasket

6.

Apply a thin coat hydro fluid to the rubber gasket on

the replacement filter.

7.

Install replacement hydraulic filter onto the filter

adapter. Do not tighten.

8.

Remove plastic bag from reservoir opening and allow

filter to fill with hydraulic fluid.

9.

When the hydraulic filter is full, turn the oil filter

clockwise until the rubber gasket contacts the filter

adapter, then tighten the filter an additional 1/2 turn

(Figure 61).

10.

Clean up any spilled fluid.

11.

If there is no fluid, add Mobil 1 15W-50 synthetic

motor oil or equivalent synthetic oil to approximately

1/4 inch (6 mm) below the top of reservoir baffle.

Important:

Use oil specified or equivalent. Other

fluids could cause system damage.

12.

Start engine and let run for about two minutes to purge

air from the system. Stop the engine and check for

leaks. If one or both wheels will not drive, refer to

Bleeding Hydraulic System.

13.

Recheck level and add fluid, if required. Do not overfill.

Bleeding the Hydraulic System

The traction system is self bleeding, however, it may be

necessary to bleed the system if fluid is changed or after work

is performed on the system.

Air must be purged from the hydraulic system when any

hydraulic components, including oil filter, are removed or

any of the hydraulic lines are disconnected. The critical area

for purging air from the hydraulic system is between the

oil reservoir and each charge pump located on the top of

each variable displacement pump. Air in other parts of the

hydraulic system will be purged through normal operation

once the charge pump is primed.

1.

Disengage the PTO and set the parking brake.

2.

Stop the engine and wait for all moving parts to stop

before leaving the operating position.

3.

Raise the rear of the machine up onto jack stands high

enough to raise the drive wheels off the ground.

4.

Check the hydraulic fluid level.

5.

Start the engine and move the throttle control to the

full throttle position. Move the speed control lever to

the middle speed position and place the drive levers

into the drive position.

If either drive wheel does not rotate, it is possible

to assist the purging of the charge pump by carefully

rotating the tire in the forward direction.

Note:

It is necessary to lightly touch the charge pump

cap with your hand to check the pump temperature. If

the cap is too hot to touch, turn off engine. The pumps

may be damaged if the pump becomes too hot. If either

drive wheel still does not rotate continue to next step.

Figure 62

1.

Charge pump cap

2.

Socket head screw

6.

Thoroughly clean the area around each of the charge

pump housings.

7.

To prime the charge pump, loosen two hex socket

head capscrews (Figure 62) 1-1/2 turns only. Make

sure engine is not running. Lift charge pump housing

upward and wait for a steady flow of oil to flow out

from under housing. Retighten capscrews. Do this for

both pumps.

Note:

Hydraulic reservoir can be pressurized to up to

5 psi to speed this process.

8.

If either drive wheel still does not rotate, stop and

repeat steps 4 and 5 on the respective pump. If wheels

rotate slowly, the system may prime after additional

running. Recheck hydraulic fluid level.

9.

Allow unit to run several minutes after the charge

pumps are primed with drive system in the full speed

position.

10.

Check the hydro control linkage adjustment. Refer to

Adjusting the Hydro Control Linkages.

42

Summary of Contents for 30934

Page 49: ...Schematics Electrical Schematic Rev Hydraulic Schematic Rev 49 ...

Page 50: ...Notes 50 ...

Page 51: ...Notes 51 ...