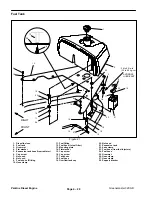

Radiator Removal (Fig. 26)

1. Park machine on a level surface, lower the cutting

units, stop the engine, engage parking brake, and re-

move the key from the ignition switch.

CAUTION

DO NOT open radiator cap or drain coolant

if the engine or radiator is hot. Pressurized

hot coolant can escape and cause burns.

Ethylene–gycol antifreeze is poisonous.

Dispose of it properly or store it in a proper-

ly labeled container away from children and

pets.

2. Place a suitable container under the front end of the

radiator. Open drain petcock (38) on the back of the ra-

diator. Drain radiator completely and close petcock.

3. Remove screen (10) from radiator support (8).

4. If the hydraulic oil cooler is installed, drain the hy-

draulic reservoir and disconnect the oil cooler (see En-

gine Removal).

5. Remove the following hoses from the radiator:

A. Loosen hose clamp (20) and disconnect breath-

er hose (24).

B. Loosen hose clamps (1) and disconnect radiator

hoses (2 and 17).

C. Loosen hose clamp (35) and disconnect air

cleaner hose (34).

6. Remove the following fasteners to remove the ra-

diator support (8) from the frame:

A. Lock nut (9) and cap screw (28) securing the al-

ternator guard (29) to the frame tab. Cap screw (7)

securing the lower radiator support to the frame.

B. Cap screw (7) securing the upper radiator sup-

port tab to the frame. Lock nut (9), cap screw (18),

and flat washer (36) securing the rear radiator sup-

port tab and R–clamp (31) to the frame tab.

7. Remove the radiator support (8) from the frame and

onto a workbench.

8. Remove four cap screws (18) and lock nuts (9) se-

curing the radiator (4) to the radiator support (8). Slide

radiator out of the support.

9. Remove four cap screws (22), lock nuts (27), and

flat washers (15) securing the fan shroud (19) to the ra-

diator (4). Separate the shroud from the radiator.

Radiator Installation (Fig. 26)

1. Secure fan shroud (19) to radiator (4) with four cap

screws (22), lock nuts (27), and flat washers (15).

2. Slide radiator (4) into the radiator support (8). Se-

cure radiator to support with four cap screws (18) and

lock nuts (9). Also, install alternator guard (29) with

washer (36) to the radiator support.

3. Position radiator support (8) to the frame.

A. Secure rear radiator support tab and R–clamp

(31) to the frame with cap screw (18), flat washer

(36), and lock nut (9). Secure upper radiator support

tab to frame with cap screw (7).

B. Secure lower portion of the radiator support to

the frame with cap screw (7). Secure alternator

guard (29) to the frame tab with cap screw (28) and

lock nut (9).

4. Connect the following hoses to the radiator:

A. Air cleaner hose (34) with hose clamp (35)

B. Radiator hoses (2 and 17) with hose clamps (1).

C. Breather hose (24) with hose clamp (20).

5. If the hydraulic oil cooler was installed, connect the

oil cooler (see Engine Installation). Fill the hydraulic res-

ervoir (see Check Hydraulic System Fluid in Chapter 5

– Hydraulic System).

6. Install screen (10) to radiator support (8).

7. Fill radiator (4) with coolant (see Check Cooling

System).

Perkins Diesel

Engine

Greensmaster 3200–D

Page 4 – 19

Perkins Diesel Engine

Summary of Contents for 3200

Page 2: ...Greensmaster 3200 3200 D ...

Page 4: ...Greensmaster 3200 3200 D ...

Page 6: ...Greensmaster 3200 3200 D ...

Page 12: ...Safety Page 1 6 Greensmaster 3200 3200 D ...

Page 14: ...Equivalents and Conversions Product Records and Maintenance Page 2 2 Greensmaster 3200 3200 D ...

Page 17: ...Product Records and Maintenance Page 2 6 Greensmaster 3200 3200 D ...

Page 72: ...Perkins Diesel Engine Page 4 30 Greensmaster 3200 D ...

Page 113: ...Hydraulic System Greensmaster 3200 3200 D Page 5 41 Hydraulic System ...

Page 161: ...Hydraulic System Greensmaster 3200 3200 D Page 5 89 Hydraulic System ...

Page 173: ...Hydraulic System Greensmaster 3200 3200 D Page 5 101 Hydraulic System ...

Page 234: ...Wheels and Brakes Page 7 12 Greensmaster 3200 3200 D ...

Page 261: ...Cutting Units Greensmaster 3200 3200 D Page 8 27 Cutting Units ...

Page 273: ......

Page 274: ...Commercial Products FORM 96 900 SL E The Toro Company 1997 Printed in U S A ...