13

Danger

When fueling, under certain circumstances, a

static charge can develop, igniting the gasoline. A

fire or explosion from gasoline can burn you and

others and damage property.

•

Always place gasoline containers on the ground

and away from your vehicle before filling.

•

Do not fill gasoline containers inside a vehicle or

on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

•

When practical, remove gasoline-powered

equipment from the truck or trailer and refuel

the equipment with its wheels on the ground.

•

If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container, not from a gasoline dispenser nozzle.

•

If you must use a gasoline dispenser nozzle, keep

the nozzle in contact with the rim of the fuel

tank or container opening at all times until

fueling is complete.

Use a fuel stabilizer/conditioner regularly during operation

and storage. A stabilizer/conditioner cleans the engine

during operation and prevents gum-like varnish deposits

from forming in the engine during periods of storage.

Important

Do not use fuel additives other than a fuel

stabilizer/conditioner. Do not use fuel stabilizers with an

alcohol base such as ethanol, methanol, or isopropanol.

1. Clean around the fuel tank cap (Fig. 12).

2. Remove the fuel tank cap.

3. Fill the fuel tank with unleaded to within 1/4 to 1/2 inch

(6 to 13 millimeters) from the top of the tank. Do not

fill into the filler neck.

Important

Do not fill the fuel tank more than 1/4 inch

(6 millimeters) from the top of the tank because the

gasoline must have room to expand.

4. Install the fuel tank cap and wipe up any spilled

gasoline.

Checking the Tire Pressure

Check the pressure of the tires because they are

overinflated at the factory for shipping. Reduce the

pressure equally in both tires to between 12 and 15 psi

(82 and 103 kPa).

Reviewing the Maintenance

Schedule

Review the Recommended Maintenance Schedule on

page 17. You may need to perform one or more additional

procedures before or soon after you begin operating the

snowthrower.

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Operating Controls

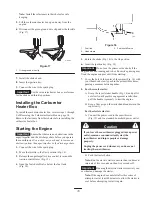

•

Auger/Impeller Drive Control Lever (Fig. 13)—To

engage both the auger and impeller, press the lever

against the right handgrip. To disengage, release the

lever.

879

1

2

3

4

6

5

Figure 13

1.

Auger/impeller drive

control lever

2.

Traction control lever

3.

Speed selector

4.

Discharge chute control

5.

Chute deflector handle

6.

Fuel shutoff valve

•

Traction Control Lever (Fig. 13)—To engage the

traction (wheel drive), press the lever against the left

handgrip. To stop the traction, release the lever.

•

Speed Selector (Fig. 13)—This control has four

positions: three forward speeds and one reverse. To

change speeds, move the speed selector to the desired

position. The lever locks in a notch at each speed

selection.

Note: Before shifting gears into or out of reverse, you

must release the traction control lever. You may shift

between any of the forward speeds without releasing the

traction control lever.

•

Discharge Chute Control (Fig. 13)—Rotate the

discharge chute control clockwise to move the

discharge chute to the left; counterclockwise to move

the chute to the right.

Summary of Contents for 38064

Page 27: ...27 ...