only) to prevent the recoil starter and/or the electric

starter from freezing up.

•

In snowy and cold conditions, some controls and

moving parts may freeze. Do not use excessive force

when trying to operate frozen controls. If you have

difficulty operating any control or part, start the

engine and let it run for a few minutes.

Operating Tips

WARNING

The rotor blades can throw stones, toys, and other

foreign objects and cause serious personal injury to

the operator or to bystanders.

•

Keep the area to be cleared free of all objects

that the rotor blades could pick up and throw.

•

Keep all children and pets away from the area

of operation.

•

Remove the snow as soon as possible after it falls.

•

If the machine does not propel itself forward on

slippery surfaces or in heavy snow, push forward on

the handle, but allow the machine to work at its own

pace.

•

Overlap each swath to ensure complete snow

removal.

•

Discharge the snow downwind whenever possible.

Maintenance

Note:

Determine the left and right sides of the machine from the normal operating position.

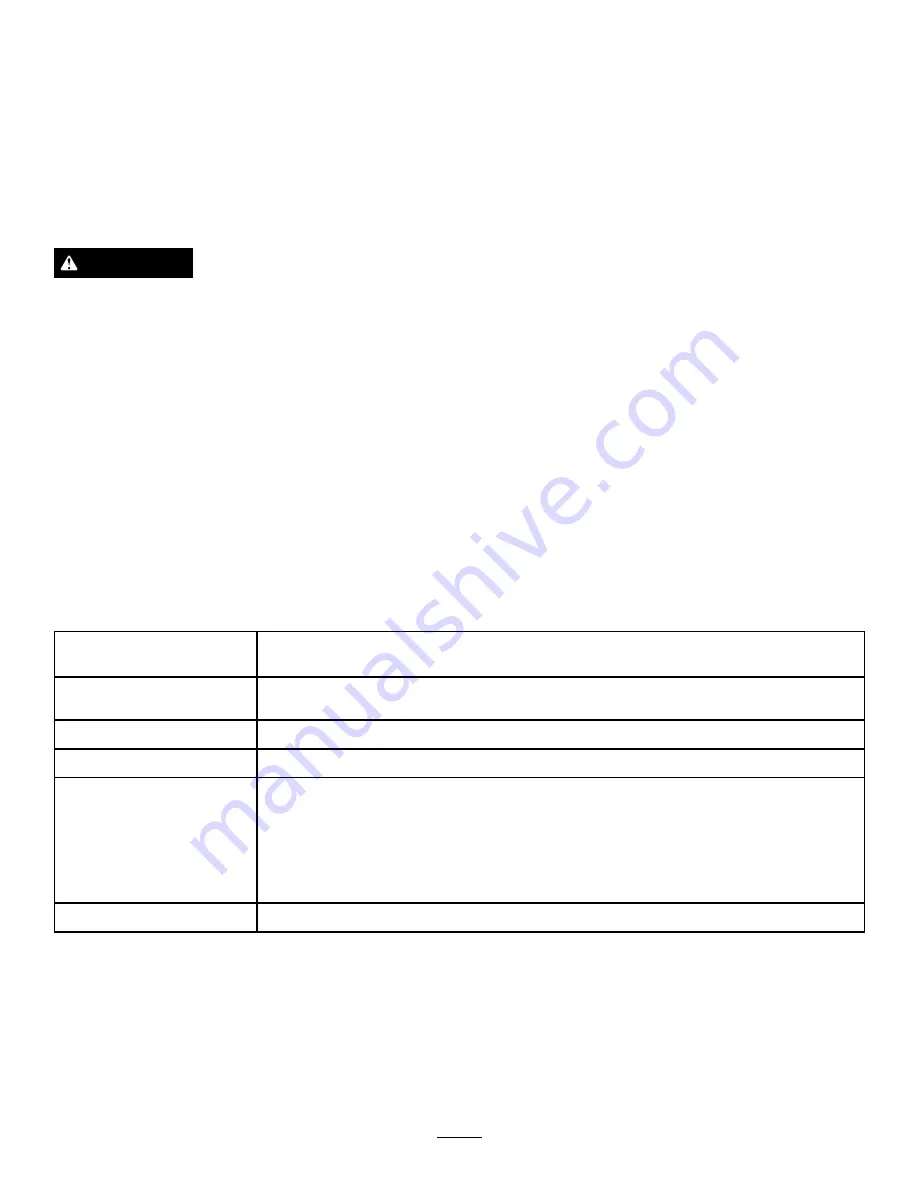

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the first hour

• Check the control cable and adjust it if necessary.

• Check for loose fasteners and tighten them if necessary.

After the first 2 hours

• Change the engine oil.

Before each use or daily

• Check the engine oil level and add oil if necessary.

Yearly

• Check the control cable and adjust it if necessary.

• Inspect the rotor blades and have an Authorized Service Dealer replace the rotor

blades and scraper if necessary.

• Change the engine oil.

• Service the spark plug and replace it if necessary.

• Check for loose fasteners and tighten them if necessary.

• Have an Authorized Service Dealer inspect the drive belt and replace it if necessary.

Yearly or before storage

• Prepare the machine for storage.

Adjusting the Control Cable

Checking the Control Cable

Service Interval:

After the first hour—Check

the control cable and adjust it if

necessary.

Yearly—Check the control cable and

adjust it if necessary.

Move the control bar back toward the handle to remove

the slack in the control cable (Figure 25).

13

Summary of Contents for 38567

Page 21: ...Notes 21 ...