3. Loosely mount the worm gear and the bracket to the

mounting flange with a bolt, a Belleville washer, and

a locknut as shown in Figure 11.

4. Slide the worm gear into the teeth of the chute

retaining ring and tighten the locknut (Figure 11).

5. Tighten the locknut that secures the chute control

bracket (Figure 10).

6. Check the operation of the chute control rod, and

move the worm gear slightly outward if it binds.

6. Filling the Engine with Oil

Procedure

Your snowthrower comes with 21 oz. (0.62 l) of oil in

the engine.

Note:

Before starting the engine, check the oil level

and add oil if necessary.

Max. fill: 21 oz. (0.62 l), type: automotive detergent

oil with an API service classification of SF, SG, SH, SJ,

SL, or higher.

•

For temperatures above 32°F (0°C), use SAE 30.

•

For temperatures between 0°F and 32°F (-18°C to

0°C), use SAE 5W30 or SAE 10.

•

For air temperatures below 0°F (-18°C), use

SAE 0W30.

1. Move the snowthrower to a level surface to ensure

an accurate oil level reading.

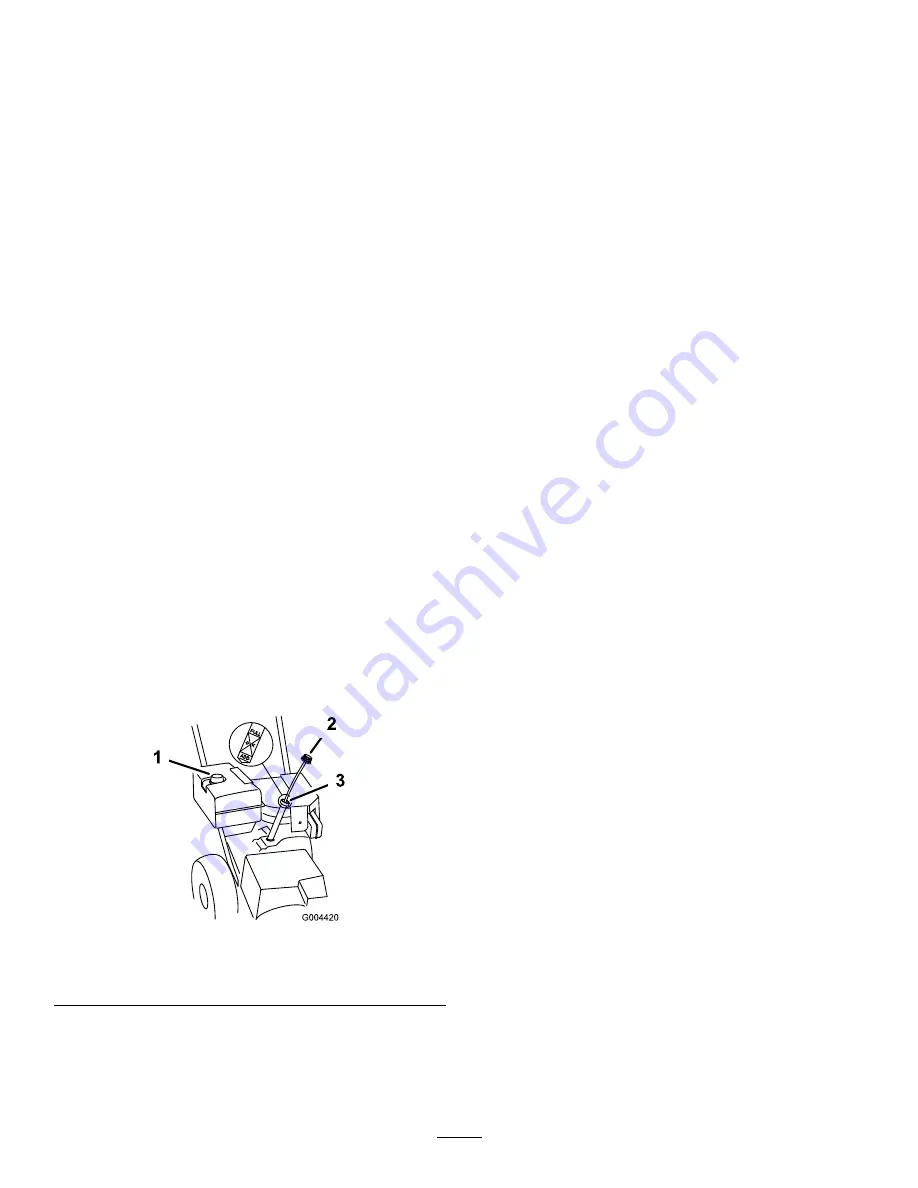

2. Clean around the dipstick (Figure 12).

Figure 12

1.

Fuel tank cap

3.

Filler hole

2.

Dipstick

3. Remove the dipstick by rotating the cap

counterclockwise and pulling it out.

4. Slowly pour about 3/4 of the crankcase capacity of

oil into the crankcase.

5. Wipe the dipstick clean with a clean cloth.

6. Install the dipstick into the filler neck, then remove it.

Note:

To ensure an accurate oil level reading, you

must fully install the dipstick.

7. Read the oil level on the dipstick.

8. If the oil level is below the Add mark on the dipstick,

slowly pour only enough oil into the filler hole to

raise the oil level to the Full mark on the dipstick.

Important:

Do not overfill the crankcase with

oil and run the engine; engine damage will

result. Drain the excess oil until the oil level on

the dipstick reads Full.

9. Insert the dipstick into the filler neck and rotate the

cap clockwise until it is tight.

7. Checking the Tire Pressure

Procedure

The tires are overinflated at the factory for shipping.

Reduce the pressure equally in both tires to between 12

and 15 psi (82 and 103 kPa).

8. Checking the Skids and

Scraper

Procedure

Refer to Checking and Adjusting the Skids and Scraper

in Maintenance.

11

Summary of Contents for 38605

Page 27: ...Notes 27 ...