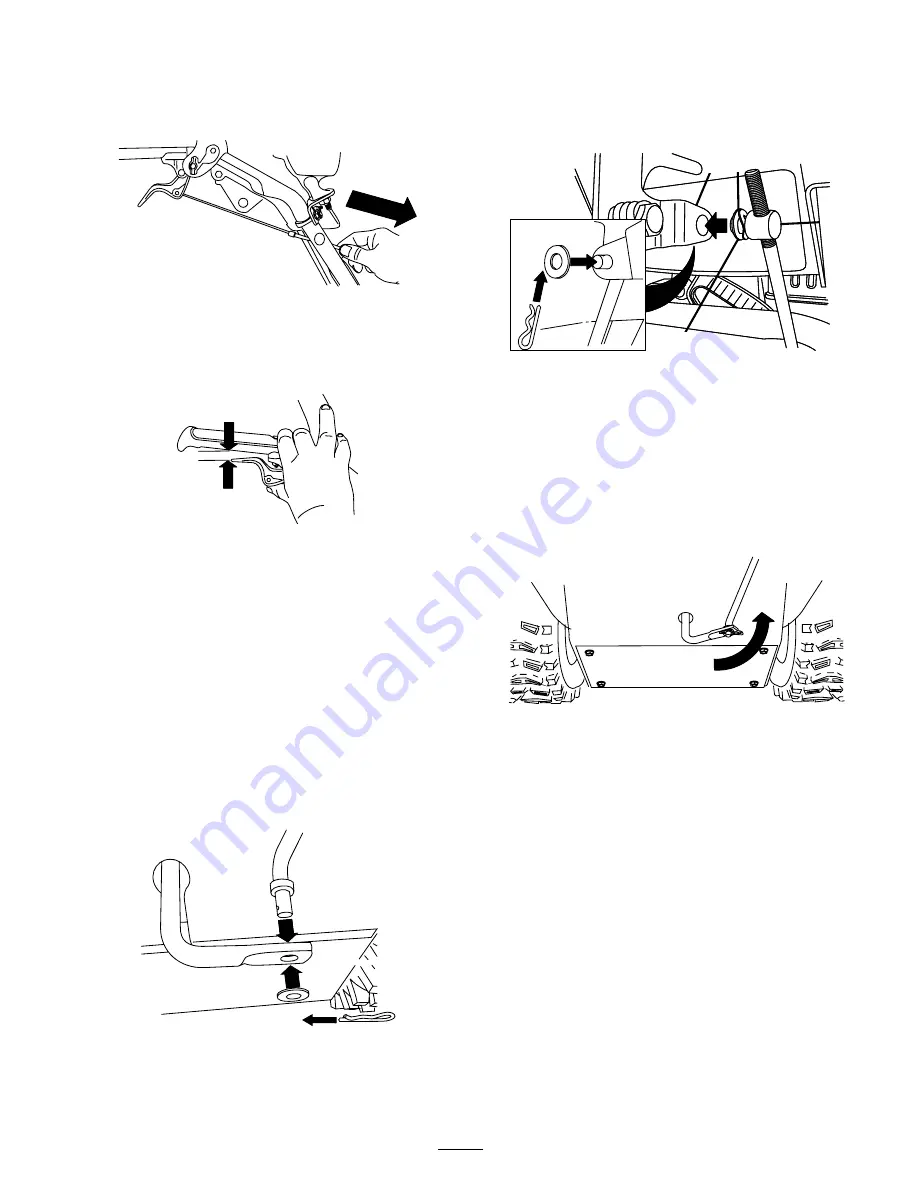

4. Pull the cable jacket down gently until the wheel clutch

lever is down and the slack is out of the cable, then

tighten the cable clamp nut securely (Figure 8).

G001305

Figure 8

5. Squeeze the lever fully, then check the gap between

the bottom of the handle and the wheel clutch lever

end (Figure 9).

G001306

Figure 9

Note:

The gap should be approximately the thickness

of a pencil (1/4 inch or 6 mm). If it is greater, loosen

the cable clamp nut, slide the cable jacket up slightly,

tighten the cable clamp nut, and check the gap again.

6. Repeat steps 2 through 5 for the other cable.

3. Installing the Traction

Control Linkage

1. Remove the hairpin cotter and washer from the lower

end of the speed control rod and insert the lower end

of the rod into the lower link arm so that the bent end

of the speed control rod faces rearward (Figure 10).

G000985

Figure 10

2. Secure the lower end of the speed control rod with the

washer and hairpin cotter that you previously removed.

3. Remove the hairpin cotter and the outer washer from

the trunnion on the upper end of the speed control rod

1 2

3

4

G000986

Figure 11

1. Speed selector lever

3. Trunnion

2. Wave washer

4. Flat washer

Note:

To make installation easier, leave the wave

washer and the

fl

at washer on the trunnion (Figure 11).

4. Shift the speed selector lever into Position R2.

5. Rotate the lower link arm fully upward

(counterclockwise) (Figure 12).

G00987

Figure 12

6. Lift up on the speed control rod and insert the trunnion

into the hole in the speed selector lever (Figure 11).

Note:

If the trunnion does not

fi

t into the hole when

you lift up on the speed control rod, rotate the trunnion

upward or downward on the speed control rod until

it

fi

ts.

7. Secure the trunnion and upper end of the speed control

rod with the outer washer and a hairpin cotter you

previously removed.

7